Conductive gel and preparation method thereof

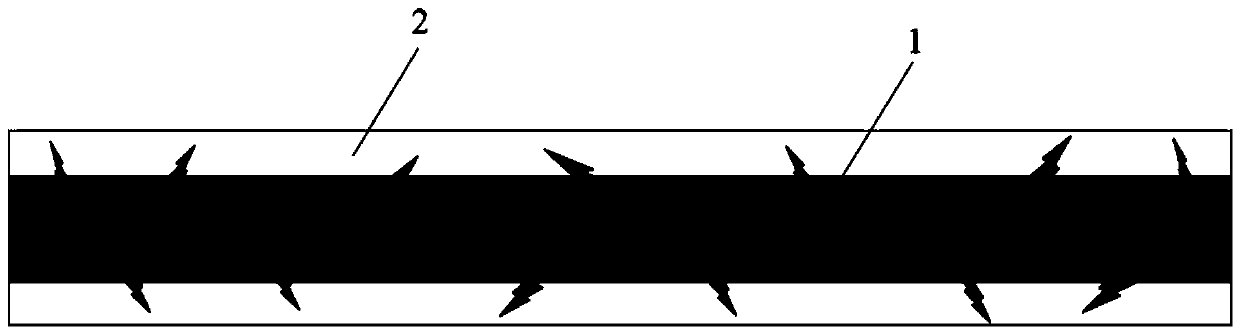

A conductive gel and gel technology, which is applied in the field of conductive gel and its preparation, can solve the problems of affecting the conductivity, the conductive gel is prone to cracks, and the device is damaged, and achieves the effects of fast and convenient preparation process and shortening the preparation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] Specifically, the preparation method comprises the following steps:

[0067] S1: adding the first conductive filler, the first polymer and the first gel factor into the first dispersion medium to prepare the first mixed solution;

[0068] S2: adding the second conductive filler, the second gel factor, and the second polymer into the second dispersion medium and mixing to prepare a second mixed solution;

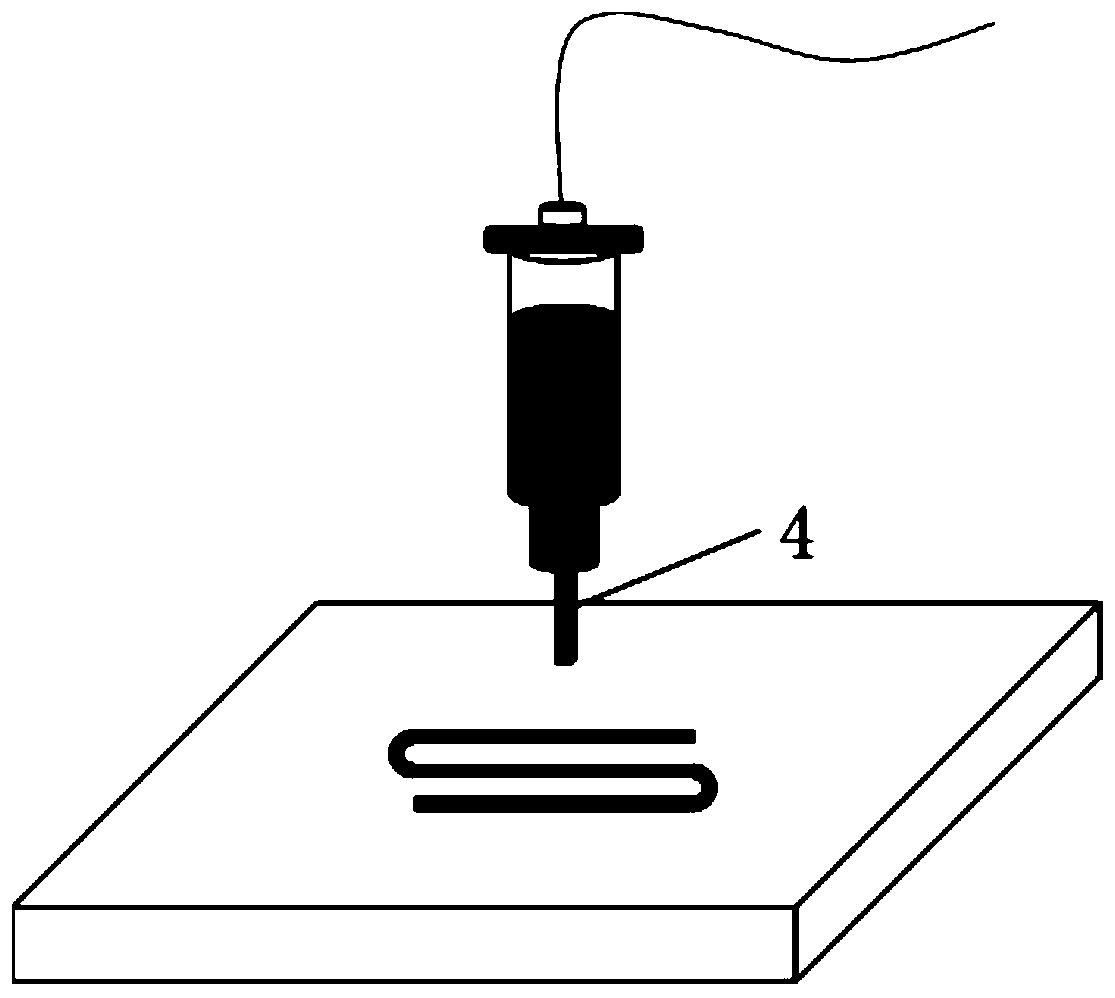

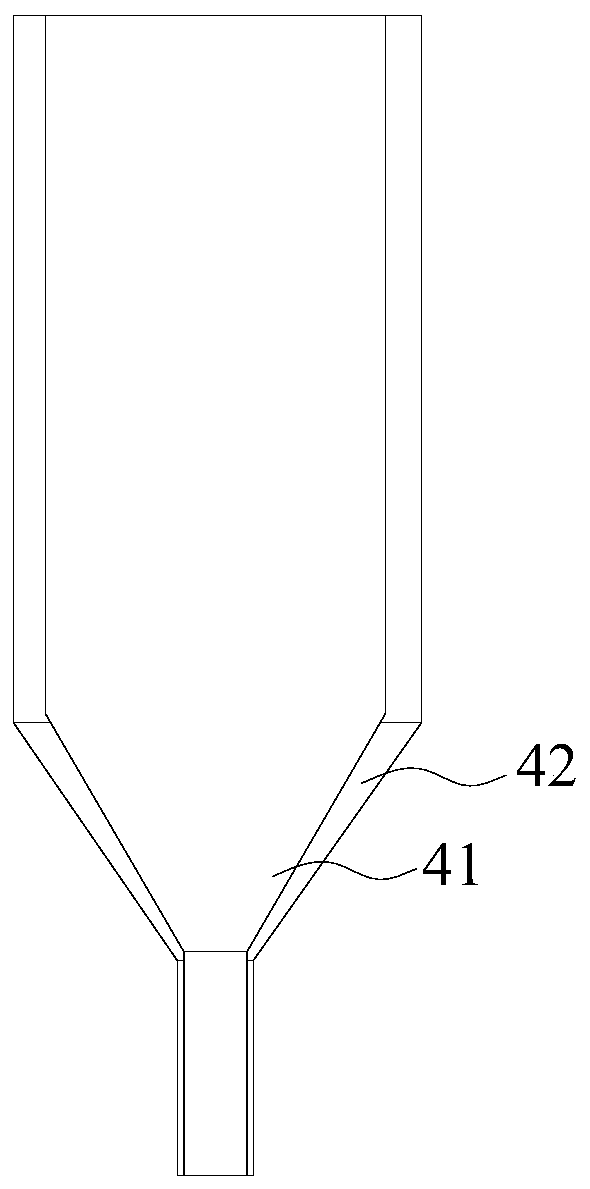

[0069] S3: Provide a printer nozzle 4, the printer nozzle 4 includes a first nozzle 41 and a second nozzle 42 covering the first nozzle 41, place the first mixed solution in the first nozzle 41, and place the second mixed solution in the second nozzle 42, and print the first mixed solution and the second mixed solution through the printer nozzle 4 to obtain a preform;

[0070] S4: Curing the preform to prepare a conductive gel.

[0071] Preferably, in step S1, the mass ratio of the first polymer, the first gelling factor, the first dispersion medium and the first con...

Embodiment 1

[0101] Add 1wt% gold nanoparticles, 0.5wt% polyacrylic acid (molecular weight: 5000), and 0.1wt% borax to 98.4wt% water and mix evenly to prepare a first mixed solution.

[0102] The sodium chloride of 1wt%, the polyvinyl alcohol (molecular weight is 10000) of 0.5wt%, the borax of 0.1wt%, the acrylamide of 10wt%, the N-N'-methylenebisacrylamide of 0.1wt% and 0.1 The wt% 2959 initiator was added into 88.2 wt% water and mixed uniformly to obtain the second mixed solution.

[0103] The first mixed solution is placed in the first nozzle, the second mixed solution is placed in the second nozzle, and printed by a printer nozzle to obtain a preform, wherein the second nozzle is sleeved on the first nozzle and arranged coaxially with the first nozzle.

[0104] The preform is cured to obtain a conductive gel.

[0105] Among them, the outer diameter of the first nozzle in the printer nozzle is 0.2mm, and the outer diameter of the second nozzle is 0.5mm; the printing speed during the pr...

Embodiment 2

[0109] This embodiment is basically the same as Embodiment 1, the only difference is:

[0110] Add 5wt% silver nanoparticles, 5wt% agarose (molecular weight: 2000), 1wt% boric acid to 89wt% water and mix evenly to prepare a first mixed solution.

[0111] Add 5wt% lithium chloride, 5wt% polyethylene glycol (molecular weight: 5000), and 1wt% boric acid into 89wt% water and mix evenly to obtain a second mixed solution.

[0112] Among them, the outer diameter of the first nozzle in the printer nozzle is 6mm, and the outer diameter of the second nozzle is 10mm; the printing speed during the printing process is 0.5mm / s, and the printing air pressure is 0.5psi; the wave band range during curing treatment is 200nm~ 400nm, light time is 5s, light intensity is 50mW / cm 2 .

[0113] The conductive gel is roughly in a double-layer core-shell structure. After testing, the outer diameter of the conductive gel is 10mm, the resistance is 20Ω / m, the elongation rate is 600%, and the Young's mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com