Boride modified Mo2FeB2-based metal ceramic and preparation method thereof

A technology based on metals and borides, which is applied in the field of boride-modified Mo2FeB2-based cermets and its preparation, can solve the problems that the hardness and fracture toughness of cermets cannot be improved at the same time, the fracture toughness is not specified in detail, and the hardness of cermets is reduced. Achieve the effects of shortening sintering time, improving comprehensive mechanical properties and reducing time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

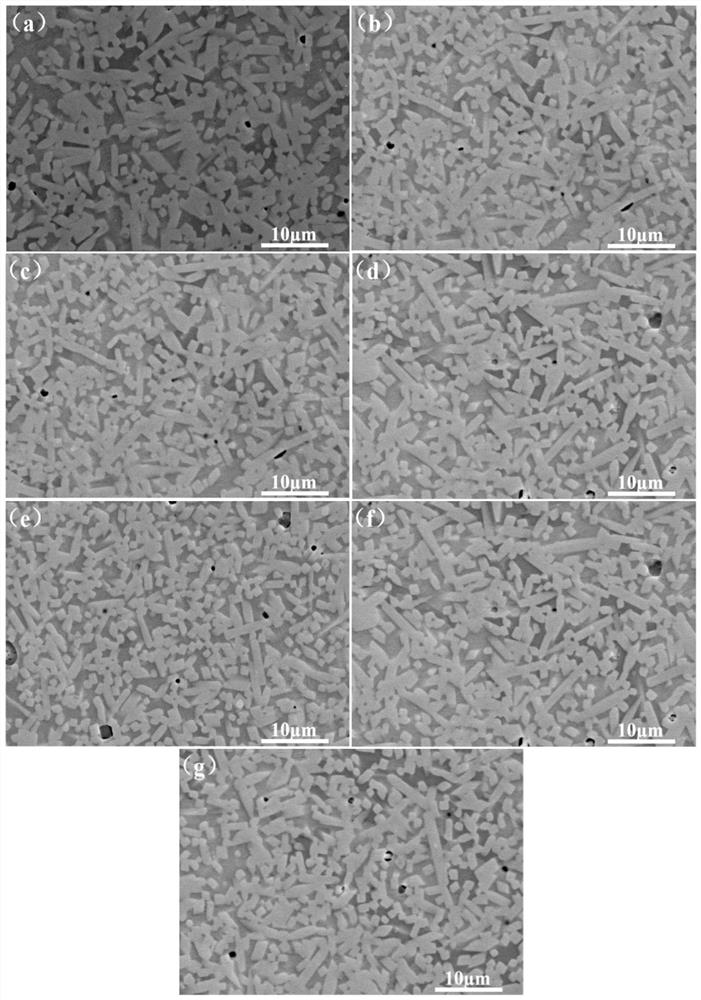

Image

Examples

Embodiment 1

[0027] A kind of boride modified Mo 2 FeB 2 A base cermet and a preparation method thereof, the raw materials are prepared through mixing, ball milling, drying, molding, and vacuum sintering, including the following steps:

[0028] S1. Mo, FeB, Fe, Cr, Ni, C and LaB with a purity of not less than 99.5% 6 Powder mixing, mixing mass ratio: Mo:44.4%; FeB:29.7%; Fe:20.125%, Cr:2.5%; Ni:2.9%; C:0.375%; LaB 6 :0%.

[0029] S2. Pour the mixed slurry into a ball milling tank, add absolute ethanol as a ball milling medium, the balls used for ball milling are cemented carbide balls, the ball-to-material ratio is 5:1, the ball milling speed is 200r / min, and the ball milling time is 36h .

[0030] S3. Put the ball-milled slurry into a vacuum drying oven, the temperature of the vacuum drying oven is 80° C., and the drying time is 2 hours.

[0031] S4. Compress the dried powder into molding, the molding pressure is 200MPa, and the holding time is 45s.

[0032] S5. Put the pressed cerm...

Embodiment 2

[0040] A kind of boride modified Mo 2 FeB 2 A base cermet and a preparation method thereof, the raw materials are prepared through mixing, ball milling, drying, molding, and vacuum sintering, including the following steps:

[0041] S1. Mo, FeB, Fe, Cr, Ni, C and LaB with a purity of not less than 99.5% 6Powder mixing, mixing mass ratio: Mo:44.4%; FeB:29.7%; Fe:19.875%, Cr:2.5%; Ni:2.9%; C:0.375%; LaB 6 :0.25%.

[0042] S2. Pour the mixed slurry into a ball milling tank, add absolute ethanol as a ball milling medium, the balls used for ball milling are cemented carbide balls, the ball-to-material ratio is 5:1, the ball milling speed is 200r / min, and the ball milling time is 36h .

[0043] S3. Put the ball-milled slurry into a vacuum drying oven, the temperature of the vacuum drying oven is 80° C., and the drying time is 2 hours.

[0044] S4. Compress the dried powder into molding, the molding pressure is 200MPa, and the holding time is 45s.

[0045] S5. Put the pressed ce...

Embodiment 3

[0053] A kind of boride modified Mo 2 FeB 2 A base cermet and a preparation method thereof, the raw materials are prepared through mixing, ball milling, drying, molding, and vacuum sintering, including the following steps:

[0054] S1. Mo, FeB, Fe, Cr, Ni, C and LaB with a purity of not less than 99.5% 6 Powder mixing, mixing mass ratio: Mo:44.4%; FeB:29.7%; Fe:19.625%, Cr:2.5%; Ni:2.9%; C:0.375%; LaB 6 :0.50%.

[0055] S2. Pour the mixed slurry into a ball milling tank, add absolute ethanol as a ball milling medium, the balls used for ball milling are cemented carbide balls, the ball-to-material ratio is 5:1, the ball milling speed is 200r / min, and the ball milling time is 36h .

[0056] S3. Put the ball-milled slurry into a vacuum drying oven, the temperature of the vacuum drying oven is 80° C., and the drying time is 2 hours.

[0057] S4. Compress the dried powder into molding, the molding pressure is 200MPa, and the holding time is 45s.

[0058] S5. Put the pressed c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com