Bubble-free fast and deep curing one-component modified PU court material and preparation method thereof

A deep curing, one-component technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of construction personnel, bulging bubbles, strict environmental temperature requirements, etc., to achieve easy mass production and construction application, The effect of low TVOC content and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

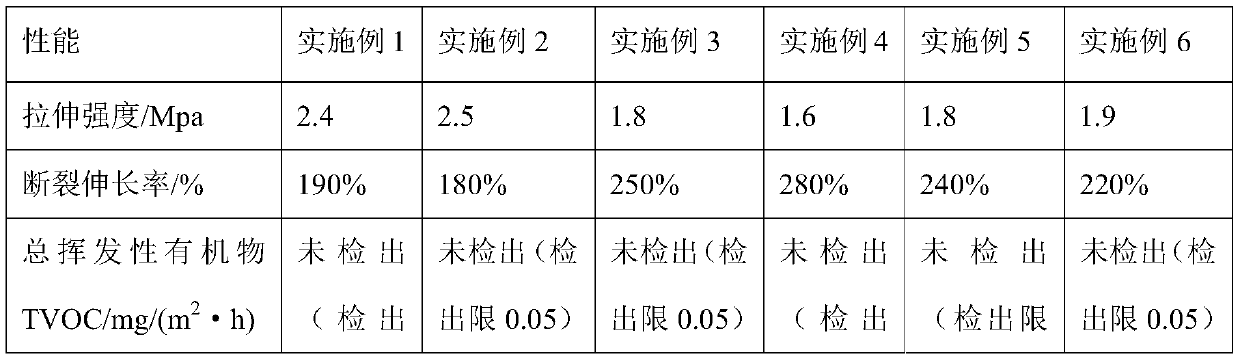

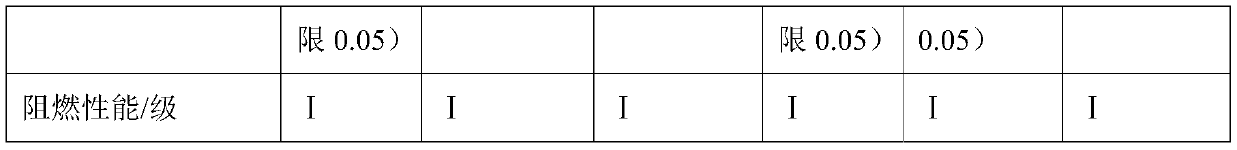

Examples

Embodiment 1

[0051]Embodiment 1 A kind of one-component modified PU court material of foam-free rapid deep layer curing, the single-component modified PU court material of foam-free rapid deep layer solidification, comprises each component of following percentage by weight:

[0052] Polyether polyol: 60g polyoxyethylene / propylene copolyethylene glycol (2000 molecular weight), 70g polyoxypropylene glycol (4000 molecular weight) and 50g polyoxypropylene trihydric alcohol (5000 molecular weight);

[0053] Isocyanate: 31.25g diphenylmethane diisocyanate;

[0054] Filler: 401.9g ground calcium carbonate;

[0055] Environmental diluent: 235.85g epoxy soybean oil;

[0056] Composite stabilizer: 8g antioxidant tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 8g ultraviolet absorber 2-(2-hydroxyl-3-dodeca Alkyl-5-methyl)benzotriazole, 8g light stabilizer bis(1,2,2,6,6-pentamethyl-4-piperidinyl) sebacate);

[0057] Latent curing agent: 50g of Incozol 4 purchased f...

Embodiment 2

[0075] A one-component modified PU court material with no foam and rapid deep curing, the one-component modified PU court material with no foam and rapid deep cure, comprising the following components in weight percentage:

[0076] Polyether polyol: 80g polyoxyethylene glycol (2000 molecular weight), 50g polyoxypropylene glycol (4000 molecular weight), 50g polyoxypropylene trihydric alcohol (5000 molecular weight);

[0077] Isocyanate: 33.75g of diphenylmethane diisocyanate;

[0078] Filler: 411.9g ground calcium carbonate;

[0079] Environmental diluent: 218.35g synthetic vegetable ester;

[0080] Composite stabilizer: 8g antioxidant triethylene glycol bis-[3-(3-tert-butyl-4-hydroxyl-5-methylphenyl) propionate], 8g ultraviolet light absorber 2-(2'- Hydroxy-3', 5'-di-tert-amylphenyl) benzotriazole and 8g light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate;

[0081] Latent curing agent: 45g of Incozol K purchased from Incorez Ltd.;

[0082] Described auxiliary ...

Embodiment 3

[0098] A one-component modified PU court material with no foam and rapid deep curing, the one-component modified PU court material with no foam and rapid deep cure, comprising the following components in weight percentage:

[0099] Polyether polyol: polytetrahydrofuran glycol (2000 molecular weight) of 70g, polyoxypropylene glycol (4000 molecular weight) of 60g, polyoxypropylene trihydric alcohol (5000 molecular weight) of 50g;

[0100] Isocyanate: 32.5g diphenylmethane diisocyanate;

[0101] Filler: 360g ground calcium carbonate;

[0102] Environmental diluent: 274.5g citric acid ester;

[0103] Composite stabilizer: 8g antioxidant 3,5-di-tert-butyl-4-hydroxyphenylpropionate isooctyl, 8g ultraviolet absorber 2-(2-hydroxy-3-dodecyl-5-methyl Phenyl) benzotriazole, 8g light stabilizer Tinuvin PUR 68 8g;

[0104] Latent solidifying agent: 42g is purchased from the Incozol HP of Incorez Ltd. company;

[0105] Described auxiliary agent comprises each component that accounts for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com