5-aminolevulinic acid production strain and its construction method and application

A technology of aminolevulinic acid and Corynebacterium glutamicum, applied in the biological field, can solve the problems of low yield, staying at the level of several grams, low ALA production level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

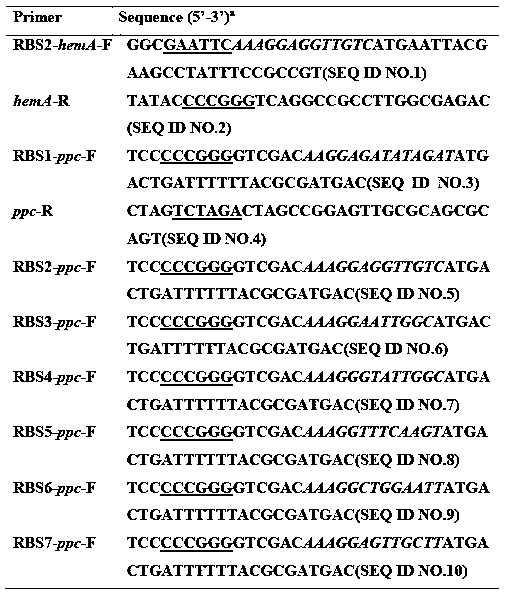

[0043] Example 1 hemA Expression optimization vector construction

[0044] According to the NCBI released Rhodopseudomonas palustris ( Rhodopseudomonas palustris ) ATCC 17001 ALA synthetase coding gene sequence (GenBank: JQ048720.1), designed primer RBS2- hemA -F (SEQ ID NO.1) and hemA -R (SEQ ID NO. 2). With pZWA1 vector (WO2014121724A, in this vector hemA The RBS sequence is RBS1) as a template to obtain the RBS2 with RBS2 hemA Gene fragments, the PCR amplification system is as follows: PCR amplification parameters are: 94°C for 10 min, 94°C for 20 s, 55°C for 30 s, 72°C for 40 s, 30 cycles, and 72°C for 5 min. target segment Eco RI and Sma I double digestion treatment, and then under the action of DNA ligase, the obtained fragment was ligated with the plasmid pEC-XK99E that was also digested, and the ligated product was transformed into DH5α competent cells, and the kanamycin-resistant plate was coated and cultured overnight , pick positive clones for colony PCR ...

Embodiment 2

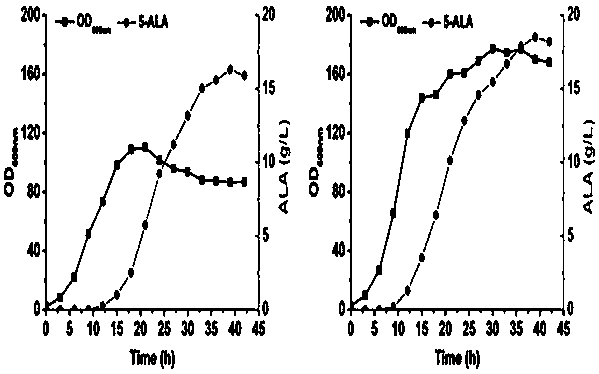

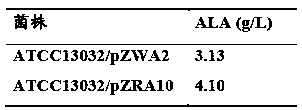

[0046] Example 2 hemA Effect of expression optimization on ALA synthesis

[0047] The above recombinant vector pZRA10 was transformed into Corynebacterium glutamicum ATCC 13032 to obtain recombinant strain ATCC13032 / pZRA10. The above-mentioned recombinant strain ATCC13032 / pZRA10 and the original strain ATCC13032 / pZWA2 were inoculated into 10 mL of LB liquid medium containing 50 μg / mL kanamycin and 20 g / L glucose, respectively, and cultured at 30 °C, 200 rpm for 12 h. According to the initial OD of 0.5, a 500 mL Erlenmeyer flask filled with 50 mL of fermentation medium was transferred, cultured at 30°C and 200 rpm for 3 h, and then IPTG with a final concentration of 100 μM was added. concentration. Wherein the shake flask fermentation medium formula is: Na 2 HPO 4 12H 2 O 17.1 g / L, KH 2 PO 4 3.0 g / L, NaCl 0.5 g / L, NH 4 Cl 1.0 g / L, MgSO 4 2mM, CaCl 2 0.1mM, glucose 50 g / L, yeast powder 2 g / L, glycine 6 g / L. The final concentration of kanamycin was 50 µg / mL. ALA de...

Embodiment 3p

[0050] Example 3 ppc Expression optimization vector construction

[0051] Utilize the same technical method of embodiment 1, through primer design and PCR amplification, obtain respectively with RBS2-RBS7 ppc Gene fragment, the primer sequence used RBS2- ppc -F, RBS3- ppc -F, RBS4- ppc -F, RBS5- ppc -F, RBS6- ppc -F, RBS7- ppc -F and ppc -R are respectively shown in Table 2, and the sequences of RBS2-RBS7 are respectively shown in Table 3. The PCR amplification system was as follows: PCR amplification parameters were: 94°C for 10 min, 94°C for 20 s, 55°C for 30 s, 72°C for 2 min, 30 cycles, and 72°C for 5 min. target segment Sma I and XbaI double digestion treatment, and then under the action of DNA ligase, the obtained fragment was connected to the pZRA8 vector of the same digestion treatment, and the ligation product was transformed into DH5α competent cells, and the kanamycin resistance plate was coated for overnight culture, and the challenge The posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com