Heat production and recovery system for cogeneration unit

A combined heat and power unit, heat recovery technology, applied in the direction of electric components, mechanical equipment, electromechanical devices, etc., can solve the problems affecting the work of the unit, low generator efficiency, temperature rise, etc., to achieve simple structure, improve efficiency, and reduce the overall The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

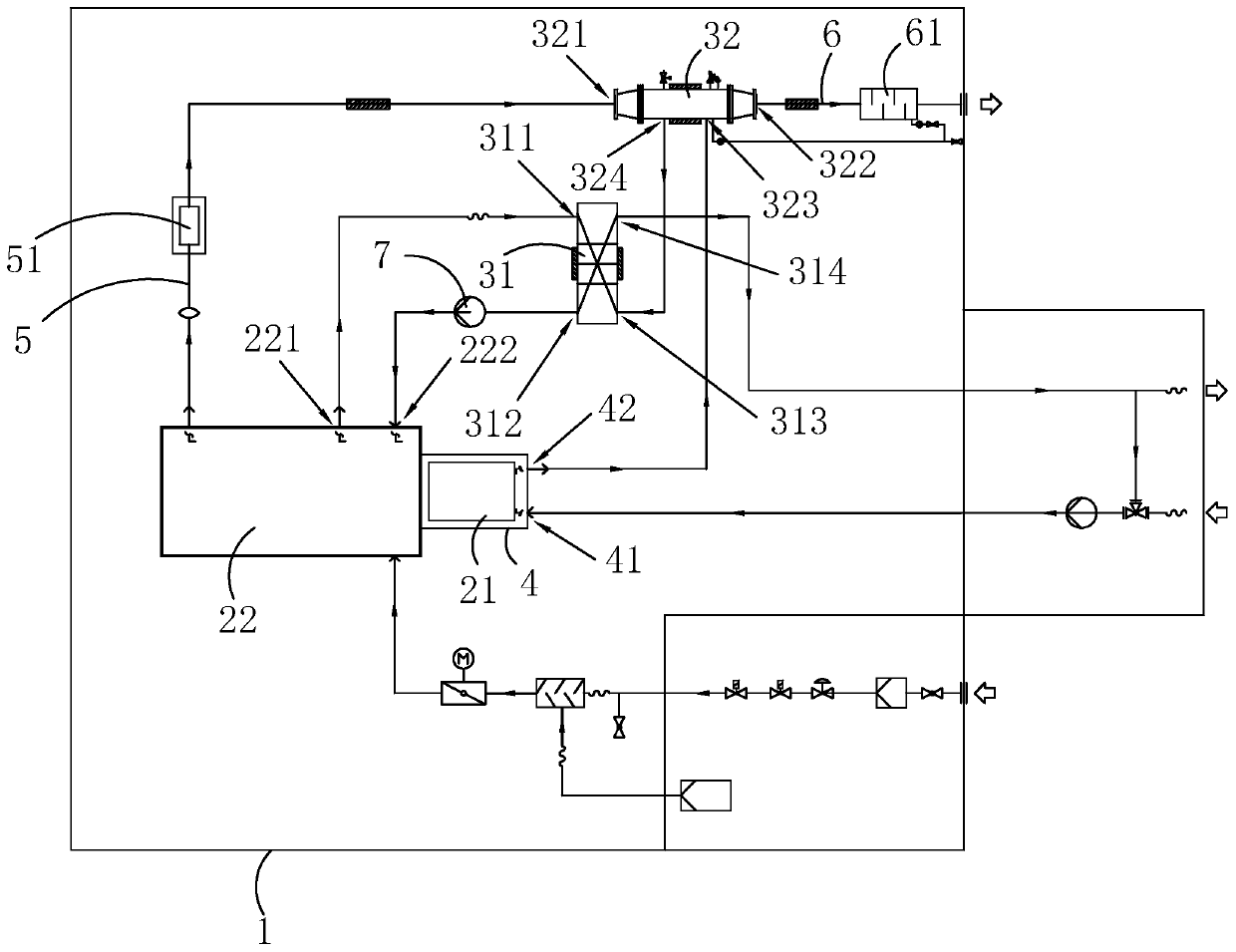

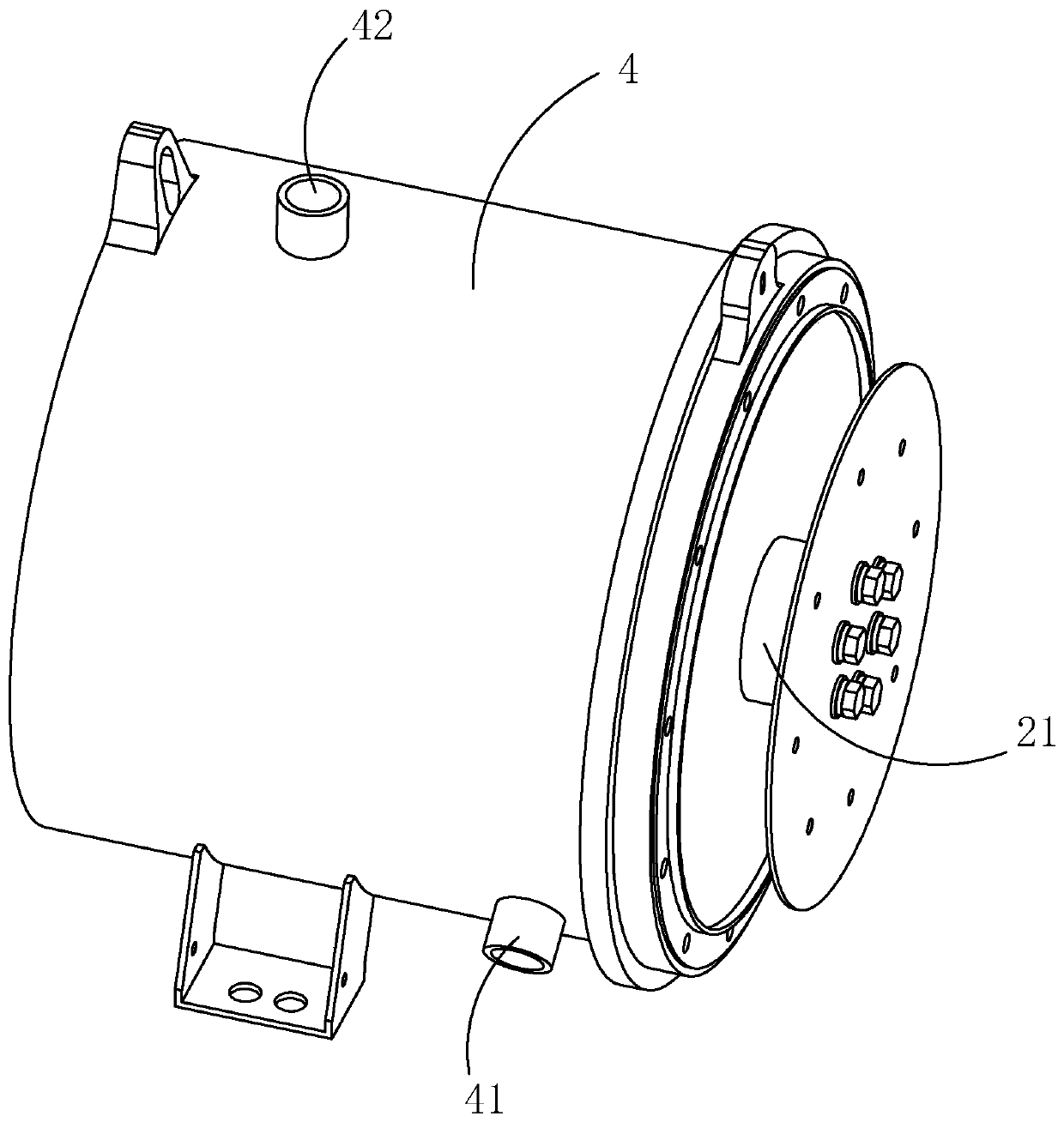

[0031] Such as figure 1 As shown, a cogeneration heat recovery system includes a body 1, a power generation system and a heat exchange system. The power generation system includes a generator 21 and an engine 22 for driving the generator 21. The engine 22 is a gas engine 22. Both the power generation system and the heat exchange system are arranged in the body 1 . The heat exchange system includes a plate heat exchanger 31 for exchanging heat of cooling water of the engine 22 and a flue gas heat exchanger 32 for exchanging heat of exhaust gas of the engine 22 .

[0032] Among them, such as figure 1 As shown, the flue gas heat exchanger 32 includes a flue gas inlet 321, a flue gas outlet 322, a first water inlet 323 and a first water outlet 324; The smoke pipe 5 is provided with a three-way catalytic converter 51; the three-way catalytic converter 51 proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com