Perovskite LED device based on surface ligand control and preparation method thereof

A light-emitting diode and perovskite technology, which is applied in the field of perovskite light-emitting diode devices and their preparation, can solve problems such as research on the electroluminescent properties of light-emitting diode devices, and achieve the goals of reducing leakage current, high repeatability, and suppressing the formation of defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

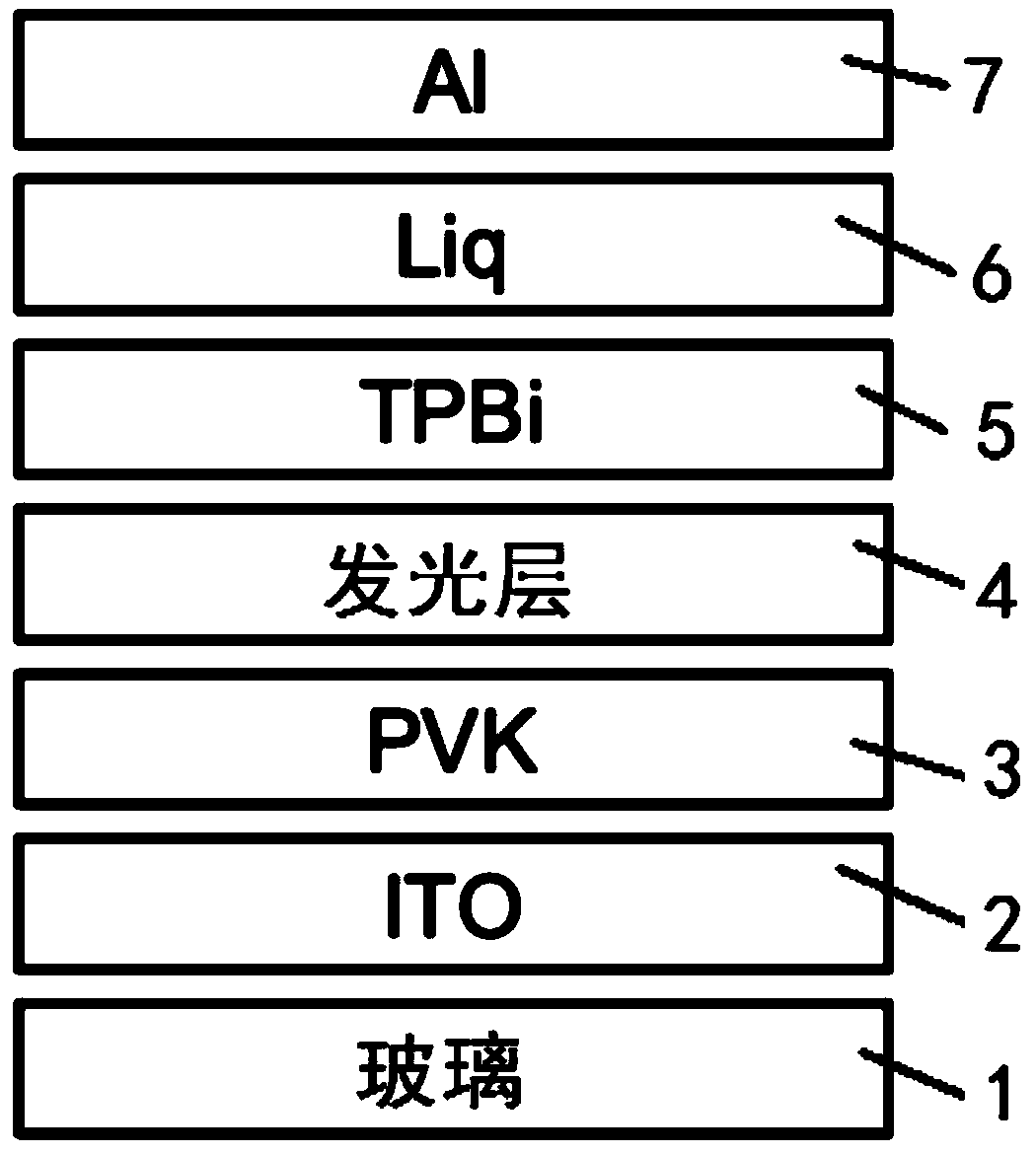

[0043] Such as figure 1 As shown, a perovskite light-emitting diode device based on surface ligand control of the present invention includes glass 1, ITO2, PVK layer 3, light-emitting layer 4, TPBi layer 5, Liq layer 6, Al electrode layer 7. Its preparation method steps are as follows:

[0044] Step 1: Use a nano-sponge dipped in cleaning agent to scrub the ITO glass and rinse it with deionized water. Place it in a beaker and put it in an ultrasonic water bath. Use ethanol, acetone and deionized water to ultrasonically clean it for 15 minutes and repeat 2-3 times. After cleaning, put the beaker containing the ITO glass in a drying oven to heat and dry it, and finally put the ITO glass face up in a watch glass, and treat it in a UV-ozone cleaning machine for 15 minutes;

[0045] Step 2: Filter the poly(9-vinylcarbazole) solution through a 0.22 μm filter head, and spin it on the ITO glass at a rotation speed of 3500-4500 rpm for 40-60 seconds, and then anneal at 100-110 ° C fo...

Embodiment 2

[0050] A preparation method of a perovskite light-emitting diode device based on surface ligand control, the preparation steps of the preparation method are as follows:

[0051] Step 1: Use a nano-sponge dipped in cleaning agent to scrub the ITO glass and rinse it with deionized water. Place it in a beaker and put it in an ultrasonic water bath. Use ethanol, acetone and deionized water to ultrasonically clean it for 15 minutes and repeat 2-3 times. After cleaning, put the beaker containing the ITO glass in a drying oven to heat and dry it, and finally put the ITO glass face up in a watch glass, and treat it in a UV-ozone cleaning machine for 15 minutes;

[0052] Step 2: Filter the poly(9-vinylcarbazole) solution through a 0.22 μm filter head, and spin it on the ITO glass at a speed of 3500-4500 rpm for 40-60 seconds, and then anneal at 100-110 ° C for 10-15 minutes;

[0053] Step 3: The precursor materials of cesium bromide, lead bromide and phenethylammonium bromide are disso...

Embodiment 3

[0057] A preparation method of a perovskite light-emitting diode device based on surface ligand control, the preparation steps of the preparation method are as follows:

[0058] Step 1: Use a nano-sponge dipped in cleaning agent to scrub the ITO glass and rinse it with deionized water. Place it in a beaker and put it in an ultrasonic water bath. Use ethanol, acetone and deionized water to ultrasonically clean it for 15 minutes and repeat 2-3 times. After cleaning, put the beaker containing the ITO glass in a drying oven to heat and dry it, and finally put the ITO glass face up in a watch glass, and treat it in a UV-ozone cleaning machine for 15 minutes;

[0059] Step 2: Filter the poly(9-vinylcarbazole) solution through a 0.22 μm filter head, and spin it on the ITO glass at a rotation speed of 3500-4500 rpm for 40-60 seconds, and then anneal at 100-110 ° C for 10-15 minutes;

[0060] Step 3: The precursor materials of cesium bromide, lead bromide and phenethylammonium bromide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com