Preparation method of curdlan oxide

An oxidation reaction and resulting technology, applied in the field of biomass materials, can solve problems such as unobtainable and affecting the health of operators, and achieve the effects of green and pollution-free prices, excellent antibacterial effects, and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Dissolve 1 g of curdlan in 50 mL of 2mol / L NaOH solution, and stir at room temperature for 2 hours to obtain curdlan aqueous solution A;

[0032] (2) Heat solution A to 60°C, add 2ml of hydrogen peroxide, stir and react for 1 hour, then add 2ml of hydrogen peroxide to react for 1 hour;

[0033] (3) the pH of the solution obtained in (2) is adjusted to 7 with hydrochloric acid of 2mol / L;

[0034] (4) After the solution obtained in step (3) was cooled to room temperature, the supernatant was filtered by a centrifuge, and the supernatant was freeze-dried to obtain 0.98 g of oxidized curdlan gum powder product. (Yield rate: 90%)

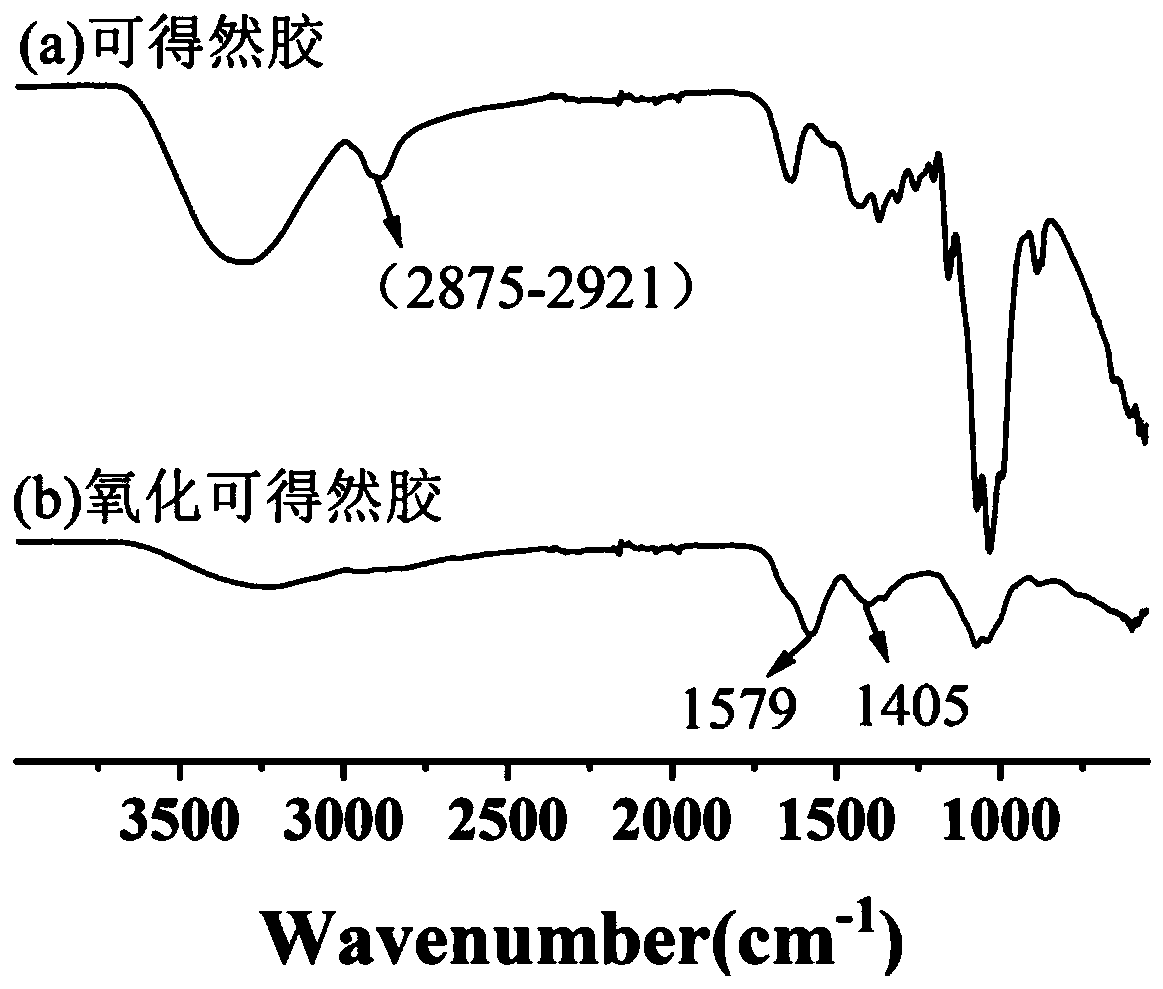

[0035] From figure 1 It can be seen that in the figure at 3360cm -1 There is a broad absorption peak nearby corresponding to the stretching vibration of the large amount of -OH in the curdlan main chain. at 2875-2921cm -1 The absorption peak corresponds to -CH 2 The CH symmetric stretching vibration group. The oxidized curdlan gum that ...

Embodiment 2

[0037] (1) Take 1 g of curdlan gum and dissolve it in 50 mL of 2mol / L NaOH solution, stir at room temperature for 3 hours to obtain curdlan gum aqueous solution A;

[0038] (2) Heat solution A to 50°C, add 2ml of hydrogen peroxide, stir and react for 1 hour, then add 1ml of hydrogen peroxide, react for one hour, add 1ml of hydrogen peroxide to react for half an hour;

[0039] (3) the pH of the solution obtained in (2) is adjusted to 7 with hydrochloric acid of 2mol / L;

[0040] (4) After cooling the solution obtained in step (3) to room temperature, filter the supernatant with a centrifuge, and freeze-dry the supernatant to obtain the oxidized curdlan gum powder product.

[0041] The oxidized curdlan powder product is a C6-position completely carboxylated oxidized curdlan product, and the yield is: 91%.

Embodiment 3

[0043] (1) Dissolve 1 g of curdlan in 50 mL of 2mol / L NaOH solution, and stir at room temperature for 2 hours to obtain curdlan aqueous solution A;

[0044] (2) Heat solution A to 60°C, add 5ml of hydrogen peroxide, stir and react for 1 hour, then add 5ml of hydrogen peroxide, and continue the reaction for one hour;

[0045] (3) the pH of the solution obtained in (2) is adjusted to 7 with hydrochloric acid of 2mol / L;

[0046] (4) After cooling the solution obtained in step (3) to room temperature, filter the supernatant with a centrifuge, and freeze-dry the supernatant to obtain the oxidized curdlan gum powder product.

[0047] The oxidized curdlan powder product is a C6-position completely carboxylated oxidized curdlan product with a yield of 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com