Mortar containing polyurethane dispersion with ethylene oxide units

A technology of polyurethane dispersion and ethylene oxide, which is applied in the field of mortar containing polyurethane dispersion with ethylene oxide units, can solve the problems of inconvenient construction site treatment and the like, and achieve good water impermeability, easy handling, good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0201] The following examples illustrate the invention without limiting it.

[0202] "Standard climate" means a temperature of 23 ± 1° C. and a relative atmospheric humidity of 50 ± 5%. "Nc" means "standard climate".

[0203] 1. Nonionic polyurethane dispersion:

[0204] PUD-N1:

[0205] 50.88 parts by weight of water were placed in a round bottom flask at a temperature of 17°C. Subsequently 28.4 parts by weight of the isocyanate-functional polyurethane polymer P1 prepared as described below, which had a temperature of 50° C., were added with good stirring while forming a milky dispersion. Immediately thereafter, 12.72 parts by weight of ice (frozen water) was added with good stirring, followed by 8.00 parts by weight of 20 wt% (2-methylpentamethylenediamine from Invista). The dispersion was stirred for another 30 minutes.

[0206] The obtained water-based polyurethane dispersion is a milky white fluid containing about 70 wt% water, 24.9 wt% chain-extended polyurethane...

Embodiment M-1

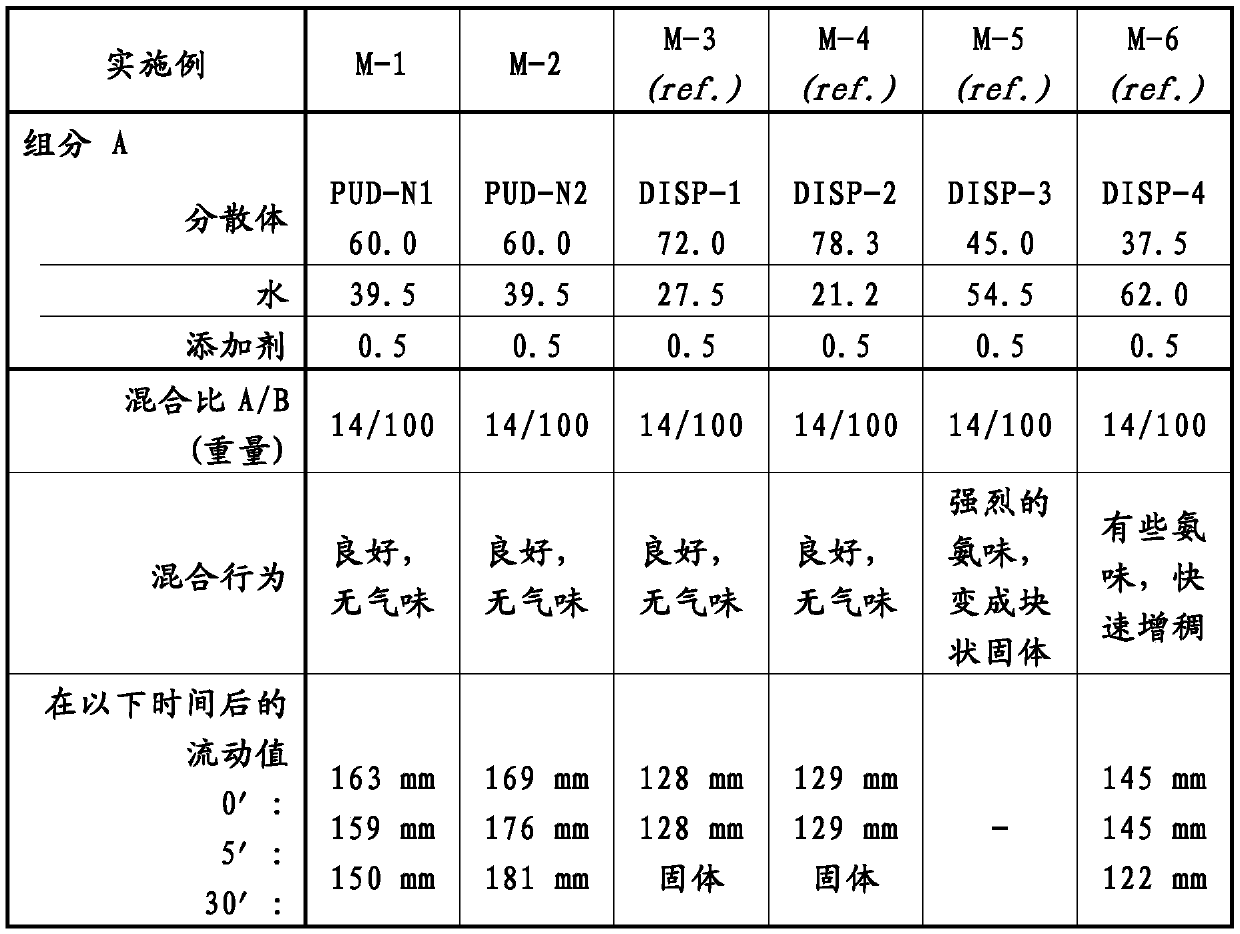

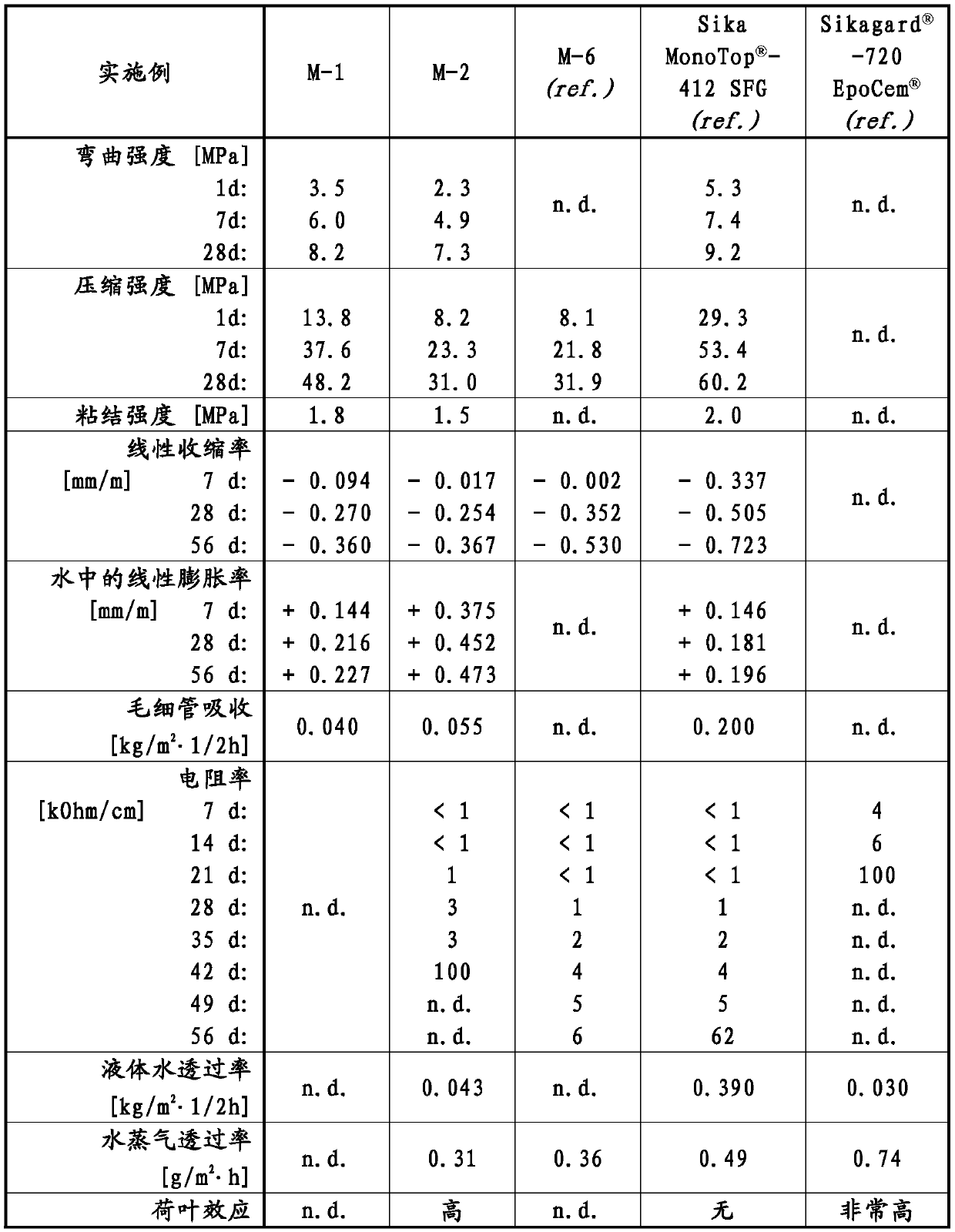

[0221] Embodiments M-1 to M-6:

[0222]For each example, liquid component A was prepared separately by mixing parts by weight of the ingredients according to Table 1. Each Component A was stored in a sealed polyethylene bottle where it was storage stable.

[0223] By blending 32.8 parts by weight of Portland cement CEM I 42.5N / SR, 63.6 parts by weight of quartz sand with a diameter of 0.1 to 2mm, 0.8 parts by weight of calcium oxide powder, 0.7 parts by weight of silica fume, 0.1 parts by weight of 6mm Long polypropylene fibers and 2 parts by weight of other mortar additives were used to prepare Component B in solid granular form. Component B is stored in sealed drums where it is storage stable. It was used in Examples M-1 to M-6.

[0224] The repair mortars of Examples M-1 to M-6 were mixed by blending each of Component A and Component B in the mixing ratio given in Table 1, and mixed within 3 minutes using a Hobart-mixer to form a homogeneous quality fresh mortar. Eac...

Embodiment M-7 and M-8

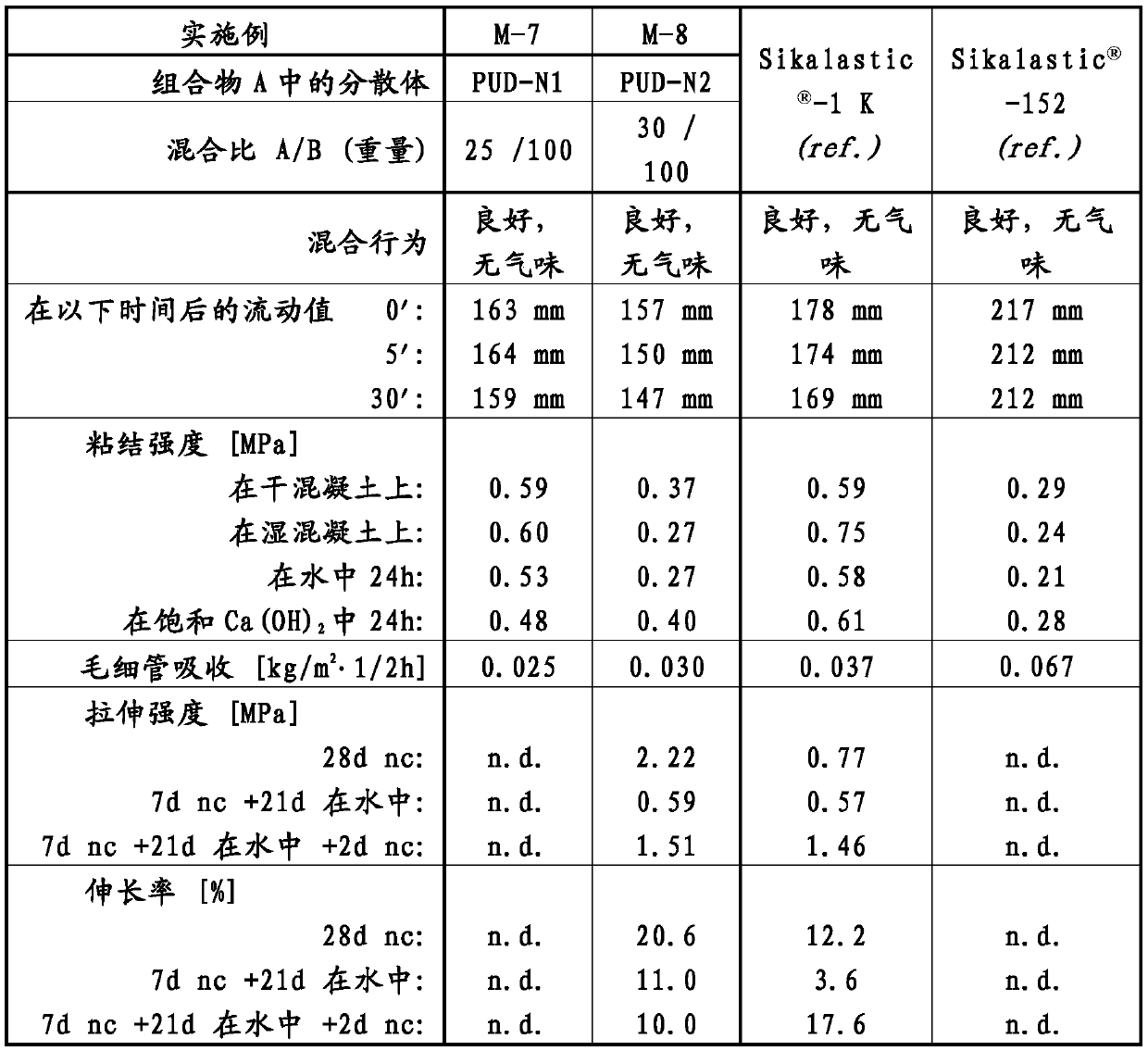

[0243] For each example, liquid component A was prepared by blending 60.0 parts by weight of PUD-N1 or PUD-N2 according to Table 3, 39.5 parts by weight of water, and 0.5 parts by weight of mortar additives, respectively. Each Component A was stored in a closed polyethylene bottle where it was storage stable.

[0244] By adding 6.0 parts by weight of Portland cement CEM I 52.5R, 63.0 parts by weight of quartz sand with a diameter of 0.1 to 0.3 mm, 20.0 parts by weight of redispersible ethylene-vinyl acetate powder, and 4.2 parts by weight of calcium carbonate Filler, 3.5 parts by weight of metakaolin, 2.5 parts by weight of silicon powder and 0.8 parts by weight of additives were blended to prepare component B in solid granular form. Component B is stored in sealed drums where it is storage stable. It was used in Examples M-7 and M-8.

[0245] The waterproof mortars of Examples M-7 and M-8 were mixed by blending each Component A with Component B in the mixing ratios given in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com