Method for immobilizing protein by using biofilm

A biofilm and protein technology, applied in the field of protein immobilization, can solve the problems of not being able to fully utilize biofilm materials, and achieve the effect of increasing the scope of use and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: the cultivation of Clostridium acetobutylicum biofilm

[0044] Clostridium acetobutylicum preserved at -80°C was inoculated in P2 medium, cultured under anaerobic conditions at 37°C to prepare seed liquid, and then the seed liquid was inoculated into anaerobic culture bottles (P2 medium plus cotton towel), and Static culture and fermentation at 37°C. Biofilms grown on cotton towels were sampled at 3, 5, and 7 days. The obtained biofilm was washed with PBS and used for polysaccharide staining and subsequent preparation of immobilized materials.

[0045] Biofilm polysaccharides were stained using FITC-labeled PNA and UEA I, which specifically recognizes D(+)-galactose and UEA I specifically recognizes L(-)-trehalose, and PI was used to stain dead cells. The result of CLSM is as figure 1 , where green indicates lectin-labeled polysaccharides, red indicates PI-labeled dead cells, and yellow is the combined color of the two. The results showed that with the...

Embodiment 2

[0046] Embodiment 2: the modification of biofilm material

[0047]The above-mentioned biofilm was first oxidized with TEMPO by adding 10 g of the biofilm to a solution containing 1 mM TEMPO and 10 mM NaBr, and then adding NaClO solution to the mixture to start the reaction. During the reaction, NaOH solution was continuously added to the system to control the pH of the system at 10, and when the pH no longer changed, a small amount of ethanol was added to terminate the reaction, and the pH was adjusted to 7.0 with HCl solution. The oxidized biofilm material was subjected to high-speed centrifugation to collect the precipitate and washed three times with deionized water.

[0048] The oxidized biofilm material was further modified with EDC / NHS by immersing the oxidized biofilm material in an MES solution (100 mM, pH 6.0) containing 434 mM EDC and 53.2 mM NHS, and incubating with shaking at room temperature for 3 h. After the precipitate was collected by centrifugation, it was w...

Embodiment 3

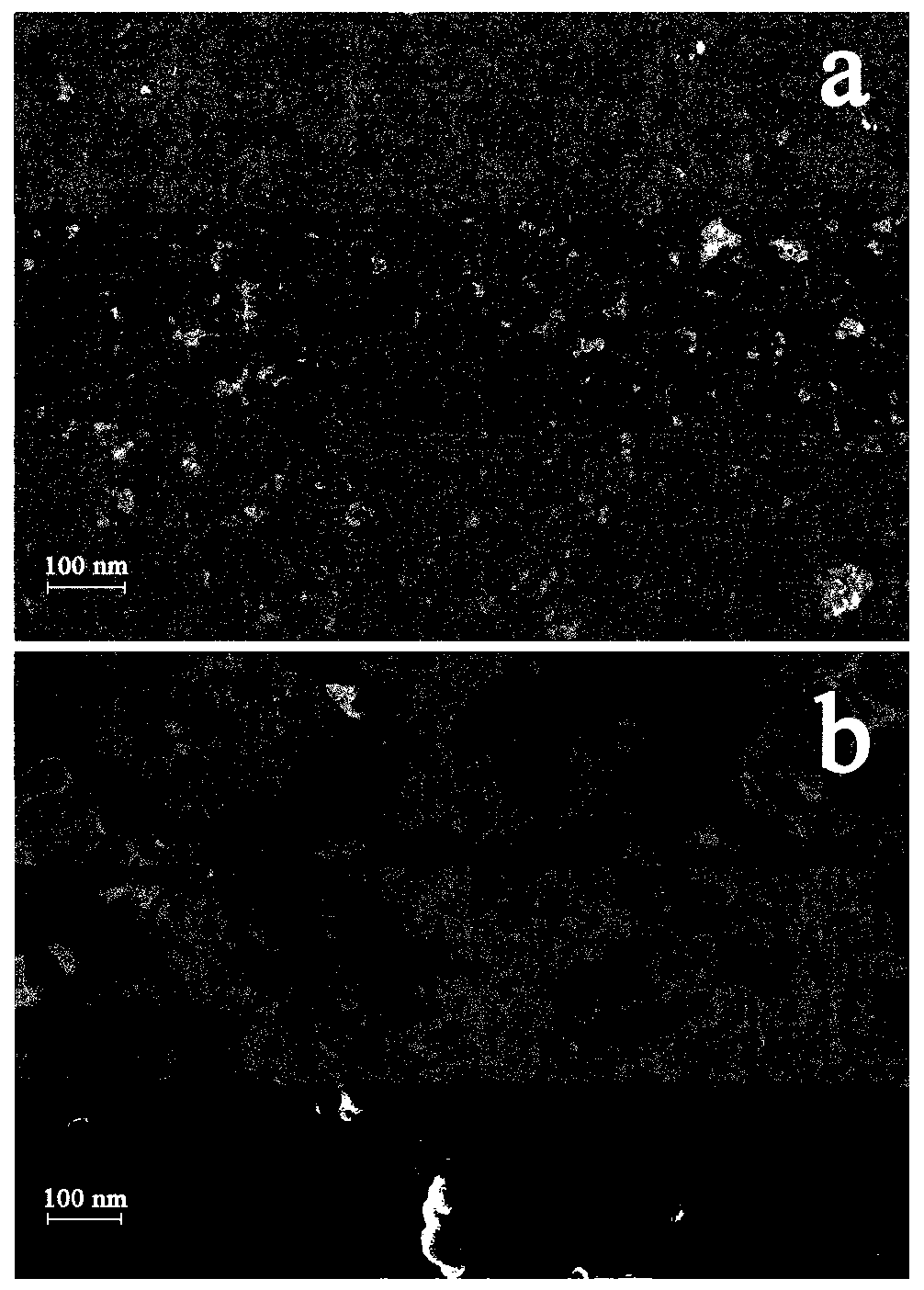

[0050] Example 3: Preparation of Magnetic Nanoparticles

[0051] Preparation of Fe using chemical co-precipitation 3 o 4 Magnetic nanoparticles by adding 1.25 g of FeCl to 100 mL of deionized water 2 4H 2 O and 3.40 g FeCl 3 ·6H 2 O, making Fe 3+ and Fe 2+ The ratio of the mixture was controlled at 2:1, and the mixture was pre-stirred at 60°C under a nitrogen atmosphere. Then 6 mL of ammonia water was added thereto, and stirring was continued for 30-40 minutes. The black precipitate was collected by centrifugation and washed thoroughly with deionized water and ethanol.

[0052] Preparation of SiO using sol-gel method 2 Covered magnetic nanoparticles, the method is: take the above 0.145g Fe 3 o 4 Magnetic nanoparticles were dispersed in ethanol, and 6 mL of deionized water and 3 mL of ammonia water were added thereto. The reaction was started by adding 0.4 mL of TEOS thereto, and the mixture was incubated with stirring at room temperature. collect solid Fe 3 o 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com