Sweetening agent compound composition capable of keeping flavor of momordica grosvenori

A compound composition and sweetener technology, applied in food ingredients as taste improvers, food science, food ingredients containing natural extracts, etc., can solve problems such as poor taste, bitterness and astringency, and improve products The effect of high value, high commercial value, and simple process route method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Compounding: The raw materials are 60 parts of Luo Han Guo sweetener—V30 product (the content of sweet glycoside V is about 30%), 5 parts of adenosine monophosphate, 7 parts of ferulic acid, 8 parts of phosphatidic acid, 2 parts of tannic acid, 5 parts of zinc lactate, 27 parts of white dextrin, 0.8 parts of honeysuckle extract, 0.6 parts of roselle extract, 0.2 parts of mulberry leaf extract, and 0.2 parts of coix seed extract. Dissolve and mix evenly to obtain a compound solution;

[0050] 2. Drying: Spray drying under the condition that the inlet temperature is 150-180°C and the outlet temperature is 70-90°C;

[0051] 3. Screening: After the spray-dried material passes through a 120-mesh sieve, the finished product is obtained;

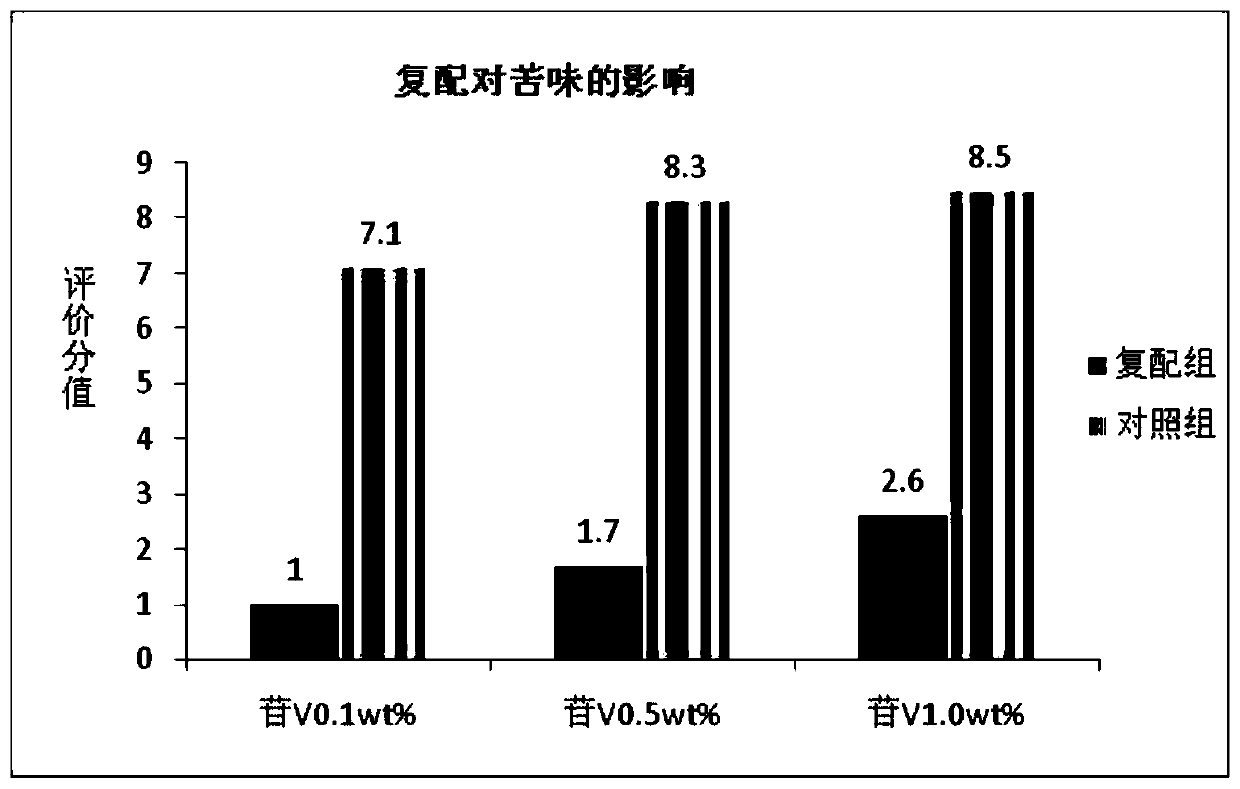

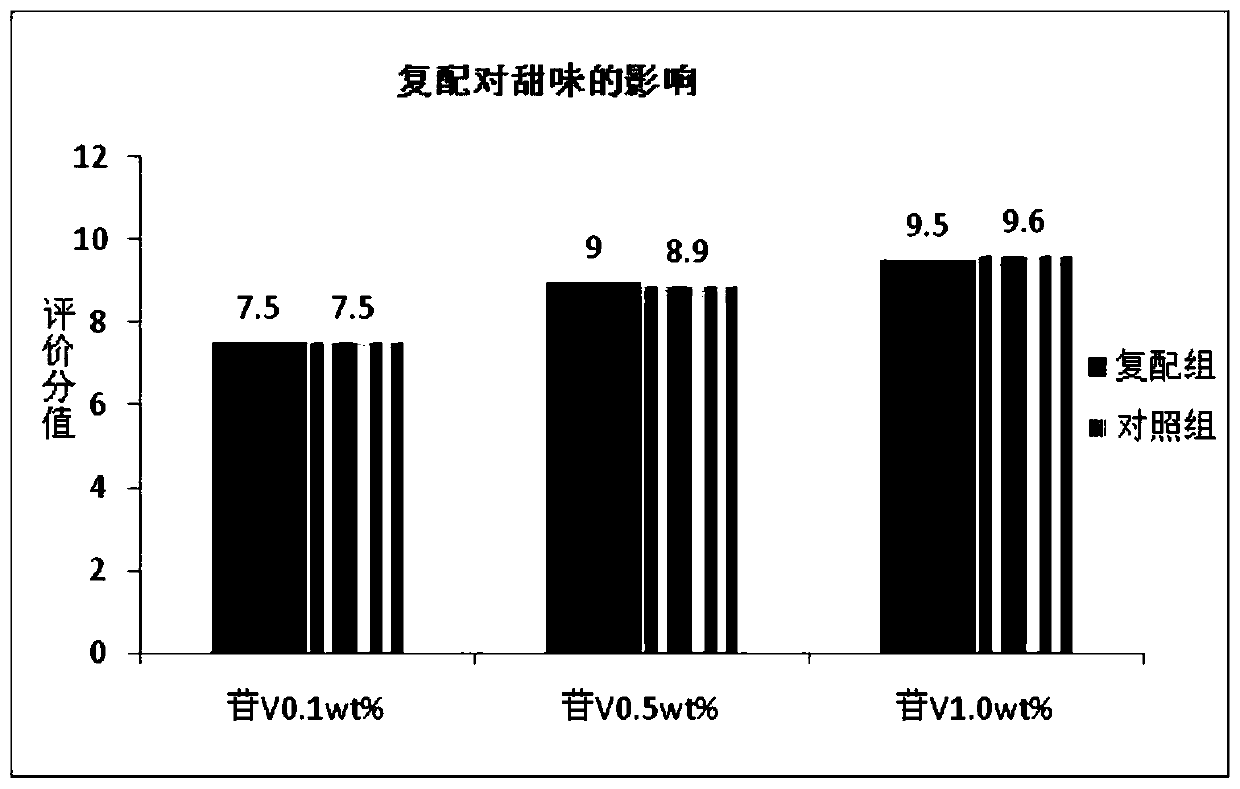

[0052] 4. Sensory evaluation: Divide the samples into a compound combination control group. The compound group consists of three different concentrations of 0.1wt%, 0.5wt% and 1.0wt% of the sieved finished product in terms of mogroside V...

Embodiment 2

[0056] 1. Compounding: The raw materials are 40 parts of Luo Han Guo sweetener—V50 product (the content of sweet glycoside V is about 50%), 2 parts of adenosine monophosphate, 3 parts of ferulic acid, 5 parts of phosphatidic acid, 3 parts of tannic acid, 1 part of zinc lactate, 25 parts of white dextrin, 0.8 parts of honeysuckle extract, 0.5 parts of roselle extract, 0.2 parts of mulberry leaf extract, and 0.2 parts of coix seed extract. Dissolve and mix evenly to obtain a compound solution;

[0057] 2. Drying: Carry out vacuum drying at 75°C and a vacuum degree of -0.1MPa.

[0058] 3. Screening: After the vacuum-dried material is crushed and passed through a 100-mesh screen, the finished product is obtained.

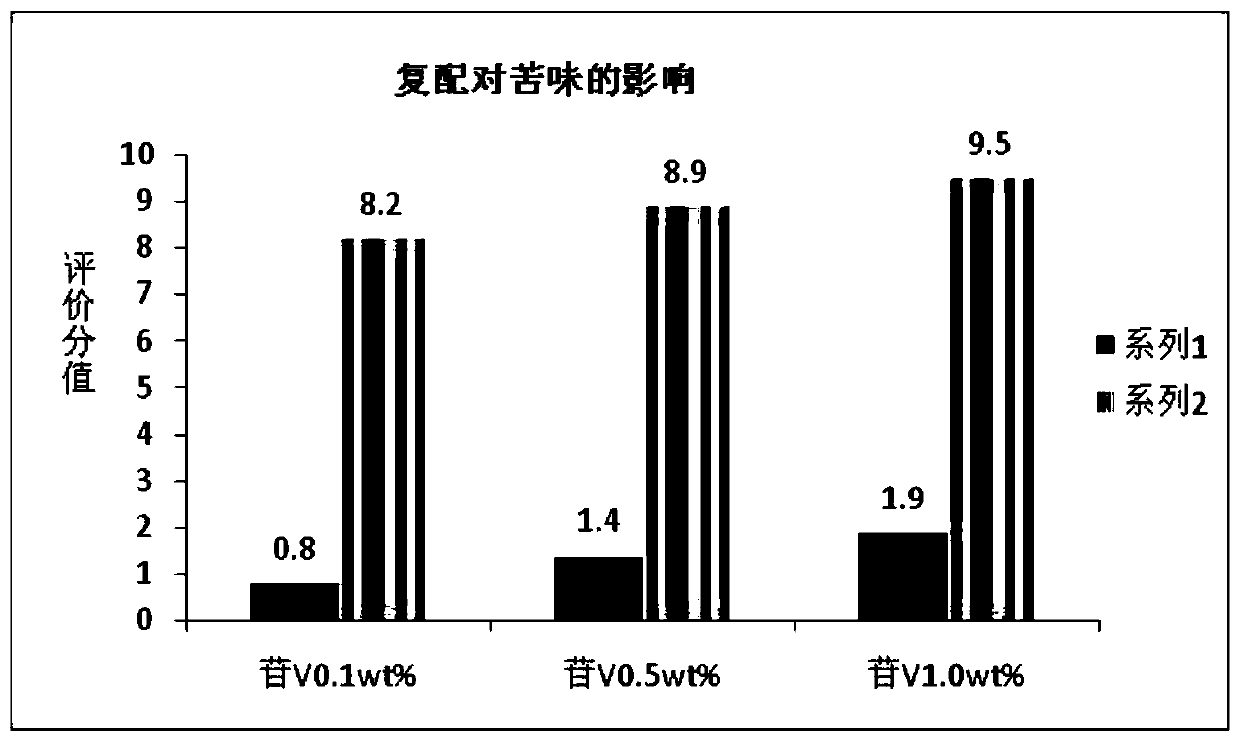

[0059] 4. Sensory evaluation: Divide the samples into a compound combination control group. The compound group consists of three different concentrations of 0.1wt%, 0.5wt% and 1.0wt% of the sieved finished product in terms of mogroside V and stir the aqueous solution ...

Embodiment 3

[0063] The method of preparing the sweet composition of Luo Han Guo is the same as that in Example 1, except that the functional extracts in the compound formula in step 1 are 1.2 parts of honeysuckle extract, 0.8 part of roselle extract, 0.3 part of mulberry leaf extract, and coix seed extract According to the compounding of 0.3 parts of substance, bitterness and sweetness are evaluated according to the same method of embodiment 1, and the results are shown in Table 3.

[0064] table 3

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com