Preparation method of dark-streak anti-counterfeiting paperboard

A dark-grain, paperboard technology, applied in the field of preparation of dark-grain anti-counterfeit paperboard, can solve problems such as poor dispersion, adverse effects on production, and huge equipment investment, and achieve the effects of high strength, increased production costs, and concealed distinguishability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a preparation method of dark-grain anti-counterfeit cardboard, which comprises: dehydrating the slurry through a forming board, then dehydrating through a forming net under vacuum, and then pressing and drying to obtain a dark-grain anti-counterfeit cardboard; It is stated that the speed difference of the bottom pulp net is -5--20m / min during the dehydration treatment of the forming net; the forming net is provided with a dark grain structure.

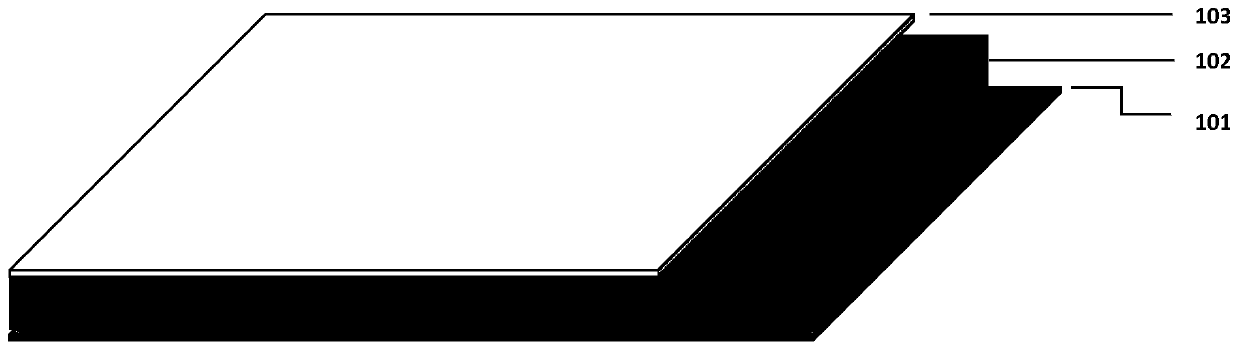

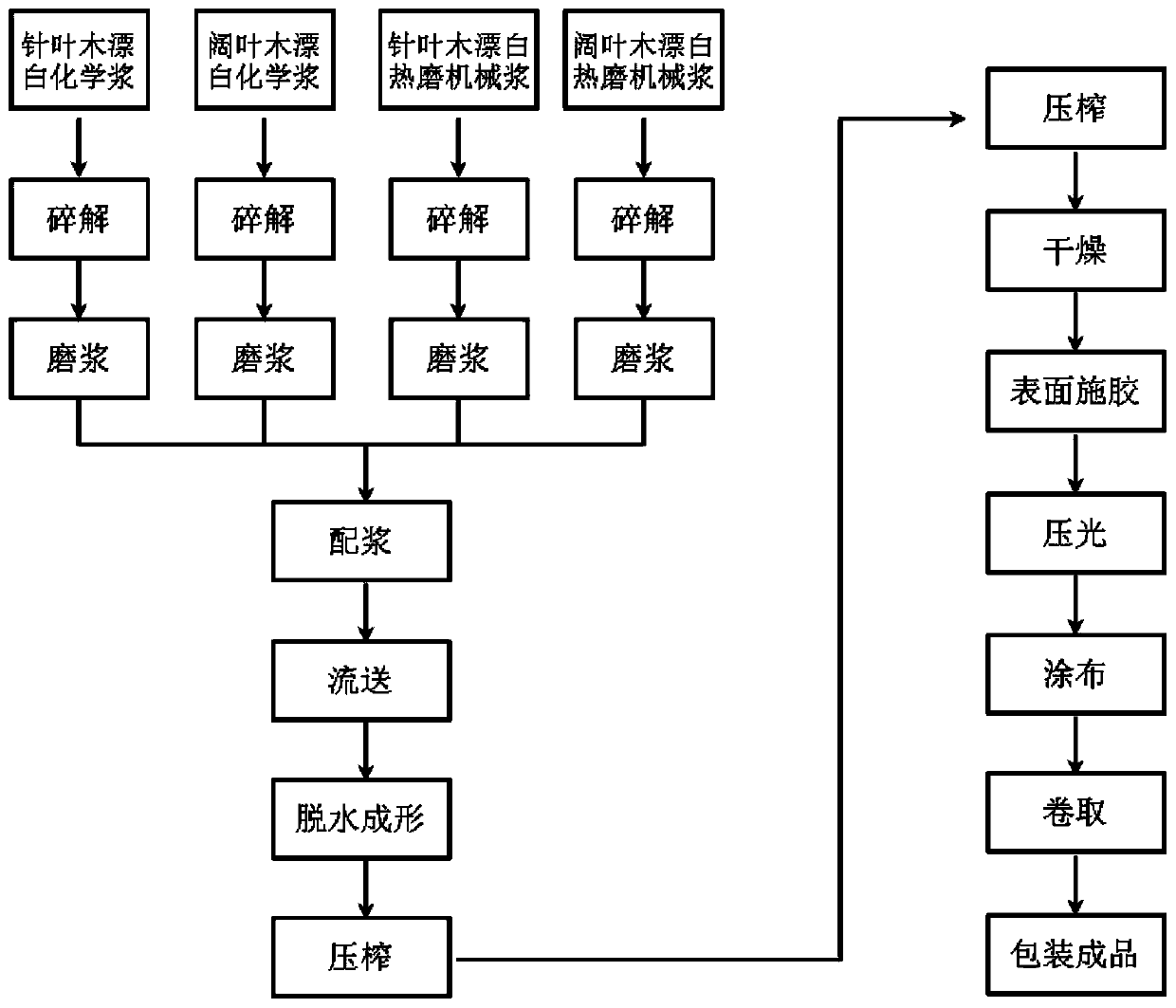

[0026] see figure 1 and figure 2 , figure 1 Schematic diagram of the structure of the dark pattern anti-counterfeiting cardboard prepared for the present invention; figure 2 It is a schematic diagram of the preparation process of the dark grain anti-counterfeiting cardboard provided by the present invention.

[0027] The present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0028] Wherein, the pulp preferably includes softwood bleached...

Embodiment 1

[0039] Such as figure 2 The schematic diagram of the paperboard preparation process is shown. The softwood bleached chemical pulp, hardwood bleached chemical pulp, softwood bleached thermomechanical pulp, and hardwood bleached thermomechanical pulp are pulped, refined and blended respectively. Among them, the proportion of softwood bleached chemical pulp is 8%, the proportion of hardwood bleached chemical pulp is 55%, the proportion of softwood bleached thermomechanical pulp is 9%, and the proportion of hardwood bleached thermomechanical pulp is 28%.

[0040] The mixed slurry is screened, slag removed, degassed and diluted in the flow delivery section, and then pumped to the headbox of each layer of the surface and core bottom. The mass concentration of the three layers of slurry after dilution is 0.3% and 1.0% respectively. , 0.3%; after the slurry is sprayed by the headbox, due to its own speed and downward gravity, the natural dehydration effect is formed at the forming pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com