Glass-sealed voltage regulation diode, tube core and manufacturing method thereof

A voltage adjustment, diode technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as the difference in thermal expansion coefficient between the die and the glass shell, device cracking, breakdown leakage, etc., to reduce leakage current, The effect of avoiding stress difference and eliminating parasitic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

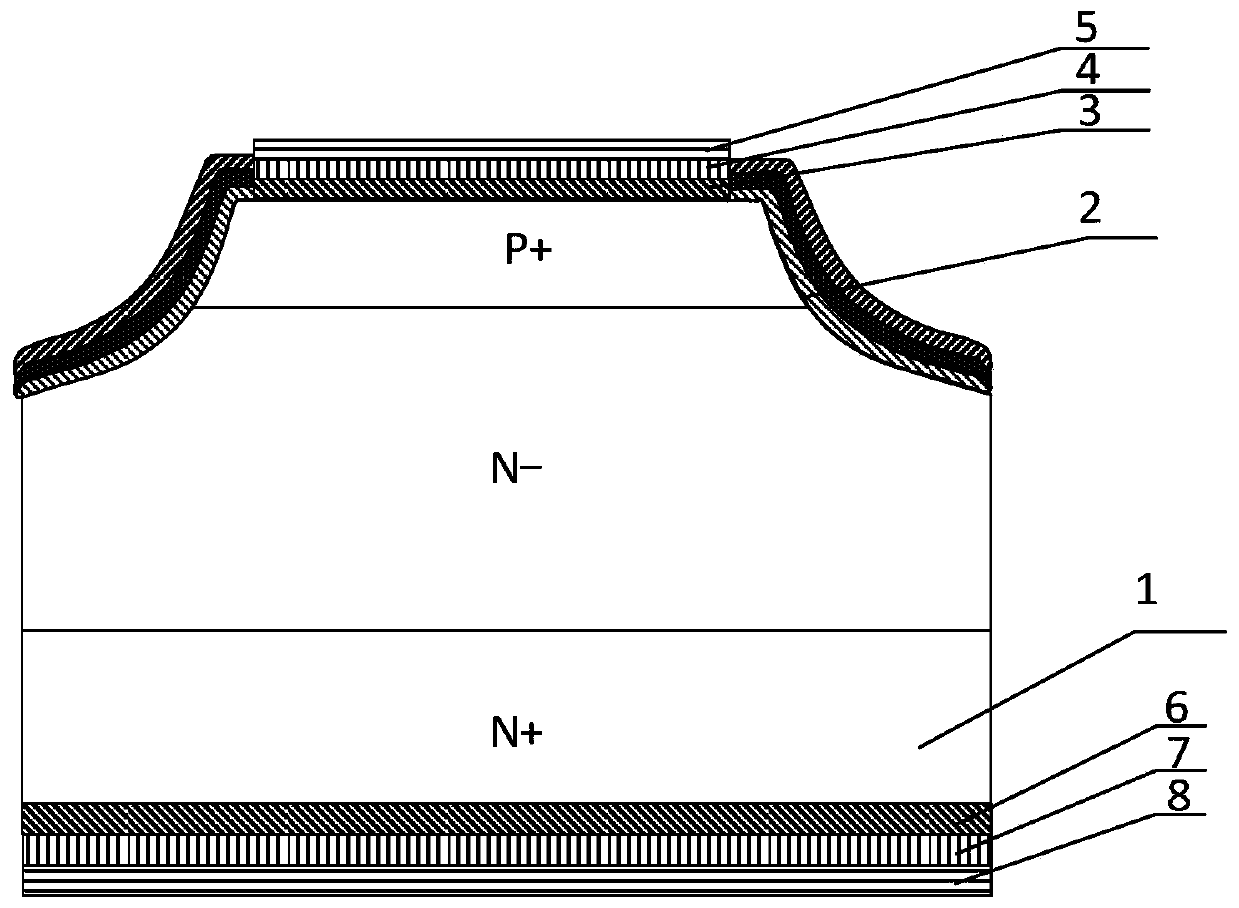

[0043] The preparation method of the above-mentioned voltage adjustment diode die includes the following steps:

[0044] s1-1. Diffusion and deep junction diffusion of the silicon wafer 1 are carried out sequentially to form a PN junction with a certain junction depth on the front side of the silicon wafer 1; the silicon wafer 1 can be an N-type silicon wafer, using N type, The thickness is 220 μm, and a PN junction is formed through a diffusion process, and a deep junction diffusion process is performed on the PN junction to form a PN junction with a junction depth of 18-22um; of course, the silicon wafer 1 can also be a P-type silicon wafer.

[0045] (s1-2), performing wet etching treatment on the periphery of the front surface of the silicon wafer 1 to generate an arc-shaped gap to form a central island area for attaching the first electrode;

[0046] (s1-3), performing passivation treatment on the front side of the silicon wafer, depositing the first silicon dioxide layer,...

Embodiment 1

[0061] In this embodiment, a glass-encapsulated voltage-adjusting diode die is prepared, which includes the following steps:

[0062] s1-1. Diffusion and deep junction diffusion of the silicon wafer 1 are carried out sequentially to form a PN junction with a certain junction depth on the front side of the silicon wafer 1; the silicon wafer 1 can be an N-type silicon wafer, using N type, The thickness is 220 μm, and a PN junction is formed through a diffusion process, and a deep junction diffusion process is performed on the PN junction to form a PN junction with a junction depth of 18 um; of course, the silicon wafer 1 can also be a P-type silicon wafer.

[0063] (s1-2), performing wet etching treatment on the periphery of the front surface of the silicon wafer 1 to generate an arc-shaped gap to form a central island area for attaching the first electrode;

[0064] (s1-3), carry out passivation treatment to the front side of the silicon wafer, deposit the first silicon dioxide...

Embodiment 2

[0076] In this embodiment, a glass-encapsulated voltage-adjusting diode die is prepared, which includes the following steps:

[0077] s1-1. Diffusion and deep junction diffusion of the silicon wafer 1 are carried out sequentially to form a PN junction with a certain junction depth on the front side of the silicon wafer 1; the silicon wafer 1 can be a P-type silicon wafer, using a P type, The thickness is 525 μm, and a PN junction is formed through a diffusion process, and a deep junction diffusion process is performed on the PN junction to form a PN junction with a junction depth of 22 μm; of course, the silicon wafer 1 can also be an N-type silicon wafer.

[0078] (s1-2), performing wet etching treatment on the periphery of the front surface of the silicon wafer 1 to generate an arc-shaped gap to form a central island area for attaching the first electrode;

[0079] (s1-3), carry out passivation treatment to the front side of the silicon wafer, deposit the first silicon dioxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com