A kind of rigid mof composite membrane preparation method for organic dye nanofiltration

An organic dye, composite membrane technology, applied in the field of materials, can solve problems such as interface defects, achieve the effects of good separation performance and stability, easy industrialization, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

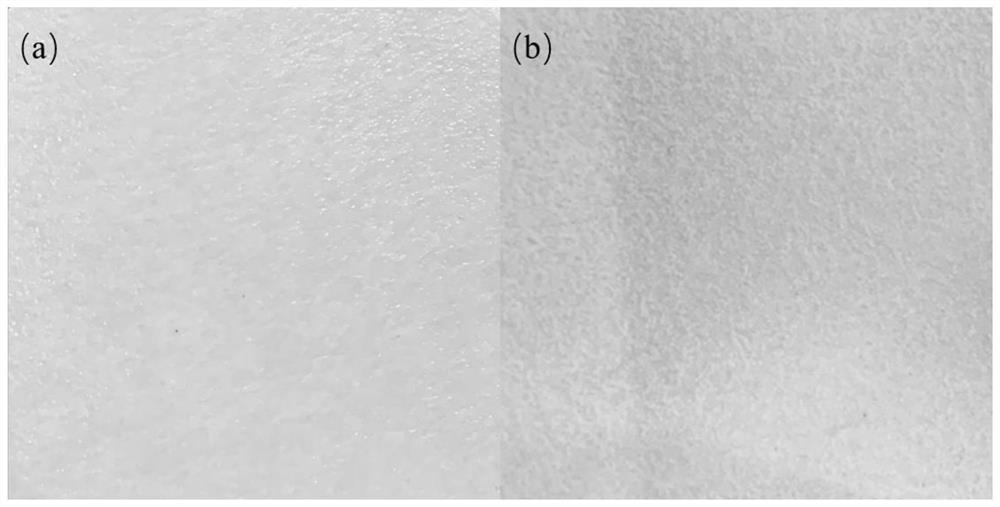

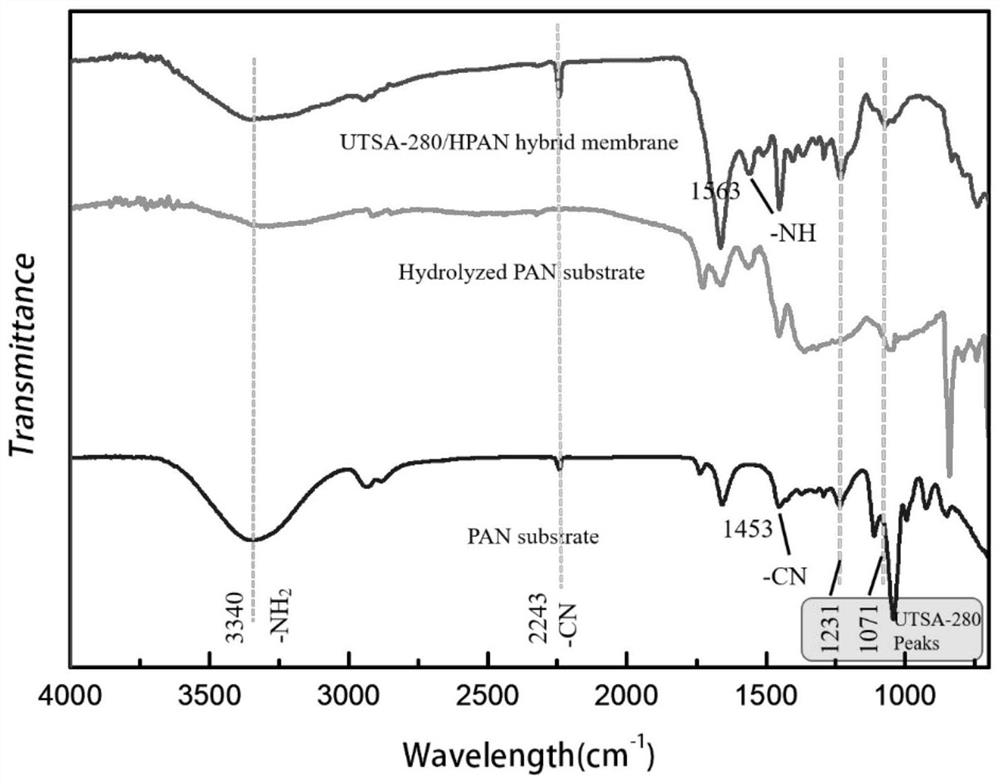

Image

Examples

Embodiment 1

[0026] The organic polymer base membrane used is a commercial polyacrylonitrile material in the form of a flat ultrafiltration membrane with a molecular weight cut-off of 200,000 and an effective diameter of 3 cm. The cross-linking agent used is polyethyleneimine, and the solvent used is deionized water.

[0027] (1) Using conventional hydrolysis modification technology, the cyano group (-CN) on the surface of polyacrylonitrile (PAN) ultrafiltration membrane is hydrolyzed into carboxyl group (-COO - ). First prepare 2mol / L NaOH solution, immerse the polyacrylonitrile ultrafiltration membrane in it at 65°C for 1 hour, and modify it into a polymer membrane with carboxyl groups on the surface;

[0028] (2) Take out the modified polymer film and rinse it with a large amount of deionized water to neutrality;

[0029] (3) NaOH, CH 3 COOH and Ca(OH) 2 4H 2 O was dissolved in 40 mL of deionized water, and under the action of ultrasonic stirring, Ca 2+ A metal ion precursor solut...

Embodiment 2

[0041] The organic polymer base membrane used is a commercial polyacrylonitrile material in the form of a flat ultrafiltration membrane with a molecular weight cut-off of 200,000 and an effective diameter of 3 cm. The cross-linking agent used is polyethyleneimine, and the solvent used is deionized water.

[0042](1) Using conventional hydrolysis modification technology, the cyano group (-CN) on the surface of polyacrylonitrile (PAN) ultrafiltration membrane is hydrolyzed into carboxyl group (-COO - ). First prepare 2mol / L NaOH solution, immerse the polyacrylonitrile ultrafiltration membrane in it at 65°C for 1 hour, and modify it into a polymer membrane with carboxyl groups on the surface;

[0043] (2) Take out the modified polymer film and rinse it with a large amount of deionized water to neutrality;

[0044] (3) NaOH, CH 3 COOH and Ca(OH) 2 4H 2 O was dissolved in 40 mL of deionized water, and under the action of ultrasonic stirring, Ca 2+ A metal ion precursor soluti...

Embodiment 3

[0055] The organic polymer base membrane used is a commercial polyacrylonitrile material in the form of a flat ultrafiltration membrane with a molecular weight cut-off of 200,000 and an effective diameter of 3 cm. The cross-linking agent used is polyethyleneimine, and the solvent used is deionized water.

[0056] (1) Using conventional hydrolysis modification technology, the cyano group (-CN) on the surface of polyacrylonitrile (PAN) ultrafiltration membrane is hydrolyzed into carboxyl group (-COO - ). First prepare 2mol / L NaOH solution, immerse the polyacrylonitrile ultrafiltration membrane in it at 65°C for 1 hour, and modify it into a polymer membrane with carboxyl groups on the surface;

[0057] (2) Take out the modified polymer film and rinse it with a large amount of deionized water to neutrality;

[0058] (3) NaOH, CH 3 COOH and Ca(OH) 2 4H 2 O was dissolved in 40 mL of deionized water, and under the action of ultrasonic stirring, Ca 2+ A metal ion precursor solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com