Water-based highlight two-component acrylic polyurethane coating and preparation method thereof

An acrylic polyurethane, two-component technology, applied in the field of coatings, can solve the problems of low performance and poor appearance of water-based coatings, and achieve the effects of small haze, high gloss, improved adhesion and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

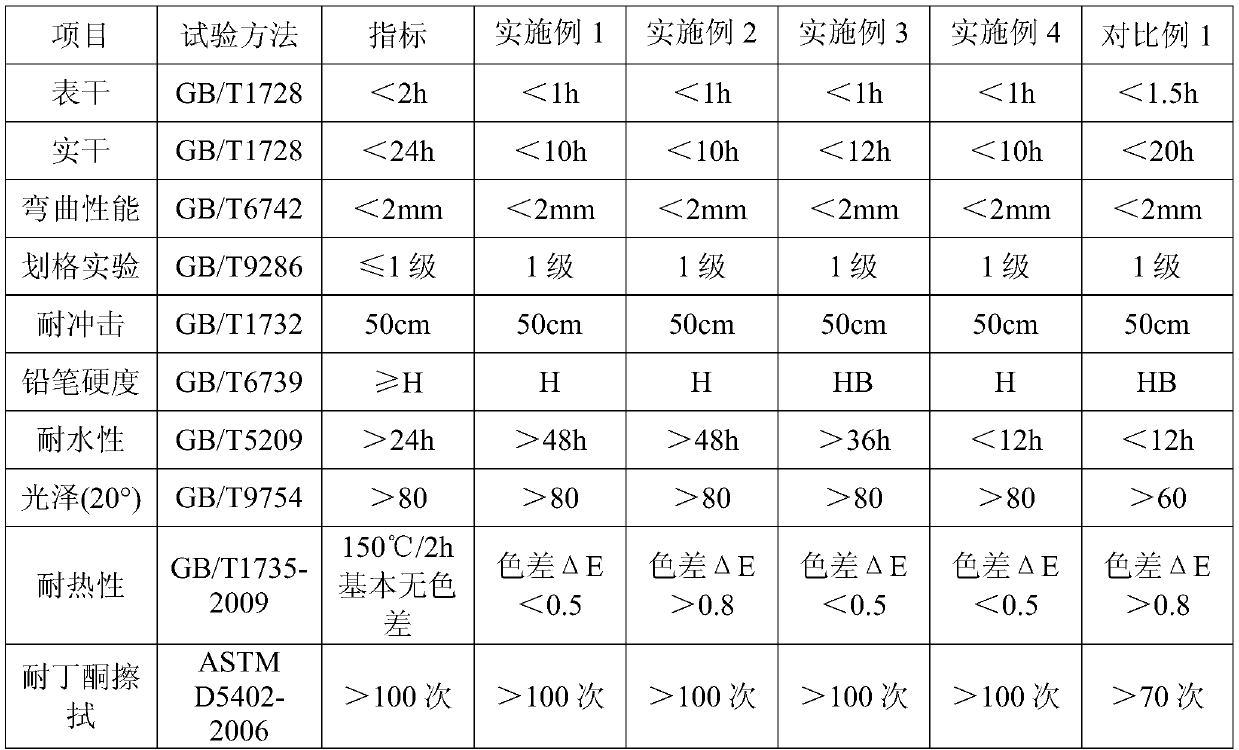

Examples

Embodiment 1

[0050] Water-based high-gloss two-component acrylic polyurethane coating, including parts by weight of the following components:

[0051] Component A: 40 parts of aqueous hydroxy acrylic dispersion, 20 parts of aqueous hydroxy acrylic dispersion II, 0.2 part of N,N-dimethylethanolamine I, 1 part of dispersant, 0.1 part of bentonite, 0.2 part of silicone defoamer, 22 parts of titanium dioxide, 0.2 parts of N,N-dimethylethanolamine II, 2 parts of ethylene glycol butyl ether, 0.3 parts of wetting agent, 0.3 parts of leveling agent, 0.2 parts of silicon-free defoamer, silane coupling agent 0.3 part, 0.5 part of antioxidant, 8 part of deionized water, 0.2 part of anti-flash rust agent, 0.2 part of thickener.

[0052] Component B: 50.4 parts of isocyanate curing agent I, 21.6 parts of isocyanate curing agent II, 7 parts of propylene glycol diacetate.

[0053] Preparation of water-based high-gloss two-component acrylic polyurethane coating:

[0054] Component A preparation:

[0055] (1) In p...

Embodiment 2

[0062] Water-based high-gloss two-component acrylic polyurethane coating, including parts by weight of the following components:

[0063] Component A: 40 parts of aqueous hydroxy acrylic dispersion, 20 parts of aqueous hydroxy acrylic dispersion II, 0.2 part of N,N-dimethylethanolamine I, 1 part of dispersant, 0.1 part of bentonite, 0.2 part of silicone defoamer, 22 parts of titanium dioxide, 0.2 parts of N,N-dimethylethanolamine II, 2 parts of ethylene glycol butyl ether, 0.3 parts of wetting agent, 0.3 parts of leveling agent, 0.2 parts of silicon-free defoamer, silane coupling agent 0.3 parts, 8 parts deionized water, 0.2 parts anti-flash rust agent, 0.2 parts thickener.

[0064] Component B: 50.4 parts of isocyanate curing agent I, 21.6 parts of isocyanate curing agent II, 7 parts of propylene glycol diacetate.

[0065] Preparation of water-based high-gloss two-component acrylic polyurethane coating:

[0066] Component A preparation:

[0067] (1) In parts by weight, control the sp...

Embodiment 3

[0074] Water-based high-gloss two-component acrylic polyurethane coating, including parts by weight of the following components:

[0075] Component A: 20 parts of aqueous hydroxy acrylic dispersion, 40 parts of aqueous hydroxy acrylic dispersion II, 0.2 part of N,N-dimethylethanolamine I, 1 part of dispersant, 0.1 part of bentonite, 0.2 part of silicone defoamer, 22 parts of titanium dioxide, 0.2 parts of N,N-dimethylethanolamine II, 2 parts of ethylene glycol butyl ether, 0.3 parts of wetting agent, 0.3 parts of leveling agent, 0.2 parts of silicon-free defoamer, silane coupling agent 0.3 part, 0.5 part of antioxidant, 8 part of deionized water, 0.2 part of anti-flash rust agent, 0.2 part of thickener.

[0076] Component B: 50.4 parts of isocyanate curing agent I, 21.6 parts of isocyanate curing agent II, 7 parts of propylene glycol diacetate.

[0077] Preparation of water-based high-gloss two-component acrylic polyurethane coating:

[0078] Component A preparation:

[0079] (1) In p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com