Flame-retardant polyamide fiber and preparation method thereof

A flame-retardant polyamide and polyamide technology, which is applied in the manufacture of fire-retardant and flame-retardant filaments, fiber processing, and conjugated synthetic polymer man-made filaments, etc., can solve the problem of poor spinnability, difficult industrial application, mechanical properties and flame Performance can not be taken into account and other problems, to achieve the effect of increasing the surface area, reducing the dosage, and improving the spinnability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of flame-retardant polyamide fiber, its specific process is as follows:

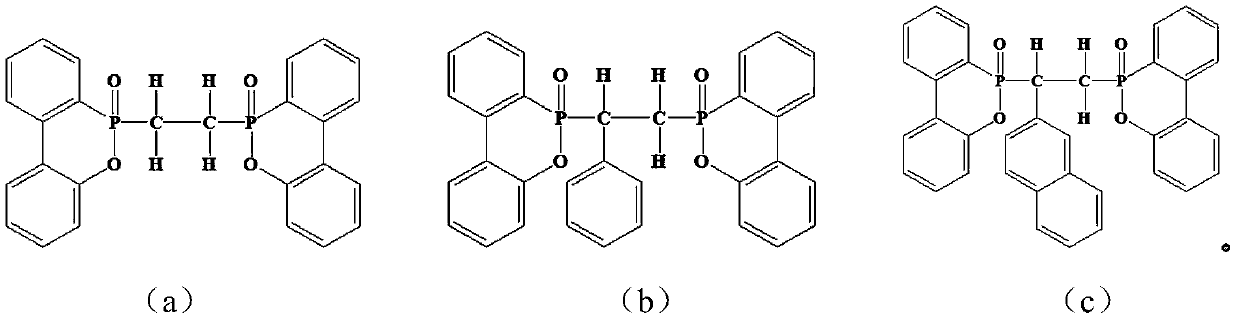

[0032] (1) 94 parts of nylon 6, 3.5 parts of melamine cyanurate, 0.5 parts of graphite-like carbon nitride, 0.5 parts of zinc sulfide and 1.5 parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene -10-Oxide derivatives were melt-blended to prepare flame-retardant polyamide chips, wherein the melt-blending temperature was 270°C, and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxidized The structural formula of the derivative is:

[0033]

[0034] (2) Dry and pre-crystallize the flame-retardant polyamide slices. The process is: firstly raise the temperature from 20°C to 65°C within 0.75h, keep it warm for 6h, then continue to heat up to 95°C within 0.75h, keep it warm for 6h, and then Continue to heat up to 115°C within 0.68h, keep warm for 12h, and finally cool down to 60°C within 0.56h;

[0035] (3) melt-spinning and drawing-winding are carried out to the polyamide c...

Embodiment 2

[0038] A kind of preparation method of flame-retardant polyamide fiber, its specific process is as follows:

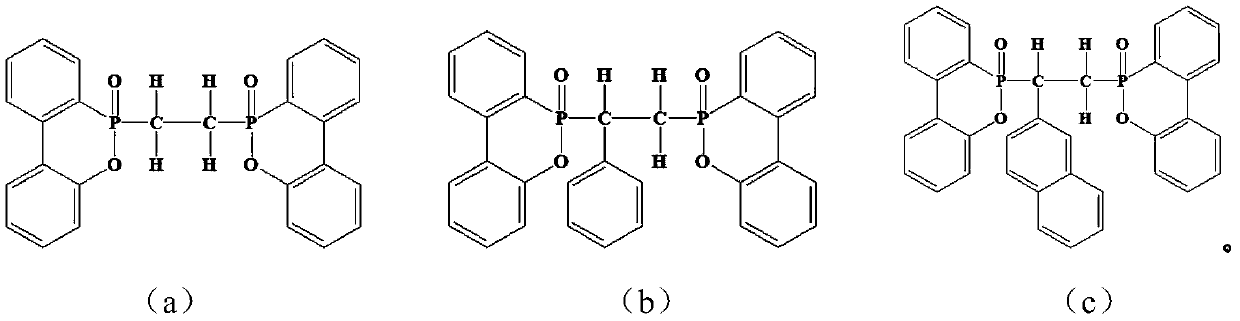

[0039] (1) 92 parts of nylon 66, 5 parts of melamine cyanurate, 0.5 parts of graphite-like carbon nitride, 0.5 parts of zinc diethylphosphinate and 2 parts of 9,10-dihydro-9-oxa- 10-Phosphaphenanthrene-10-oxide derivatives were melt-blended to prepare flame-retardant polyamide chips, wherein the melt-blending temperature was 260°C, The structural formula of phenanthrene-10-oxide derivatives is:

[0040]

[0041] (2) Dry and pre-crystallize the flame-retardant polyamide slices. The process is: firstly raise the temperature from 15°C to 50°C within 0.5h, keep it warm for 10h, then continue to heat up to 90°C within 0.5h, keep it warm for 8h, and then Continue to heat up to 110°C within 0.5h, keep warm for 15h, and finally cool down to 50°C within 0.5h;

[0042] (3) melt-spinning and drawing-winding are carried out to the processed polyamide chip of step (2) to make ...

Embodiment 3

[0045] A kind of preparation method of flame-retardant polyamide fiber, its specific process is as follows:

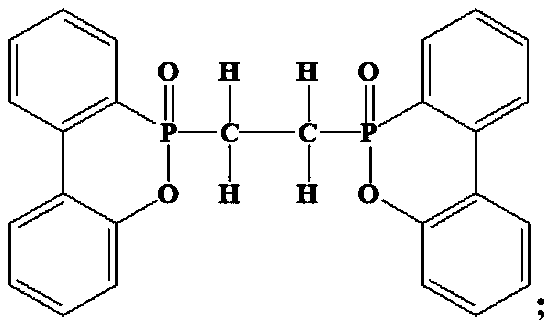

[0046] (1) 95.5 parts of nylon 56, 3 parts of melamine cyanurate, 0.4 parts of graphite-like carbon nitride, 0.4 parts of 2-carboxyethylphenyl phosphinate zinc and 1.7 parts of 9,10-dihydro-9 -Oxa-10-phosphaphenanthrene-10-oxide derivatives are melt-blended to prepare flame-retardant polyamide chips, wherein the melt-blending temperature is 280°C, and 9,10-dihydro-9-oxa- The structural formula of 10-phosphaphenanthrene-10-oxide derivatives is:

[0047]

[0048] (2) Dry and pre-crystallize the flame-retardant polyamide slices. The process is: firstly raise the temperature from 25°C to 80°C within 1h, keep it warm for 5h, then continue to heat up to 100°C within 1h, keep it warm for 4h, and then within 1h Continue to heat up to 120°C, keep warm for 8h, and finally cool down to 80°C within 1h;

[0049] (3) carry out melt spinning and draft winding to the polyamide ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com