Preparation method of all-solid-state electrolyte battery and all-solid-state electrolyte battery

A solid electrolyte and electrolyte technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, solid electrolytes, etc., can solve the problems of reducing interface impedance, energy consumption, bad interface modification layer, etc., to achieve capacity and cycle life improvement, performance Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

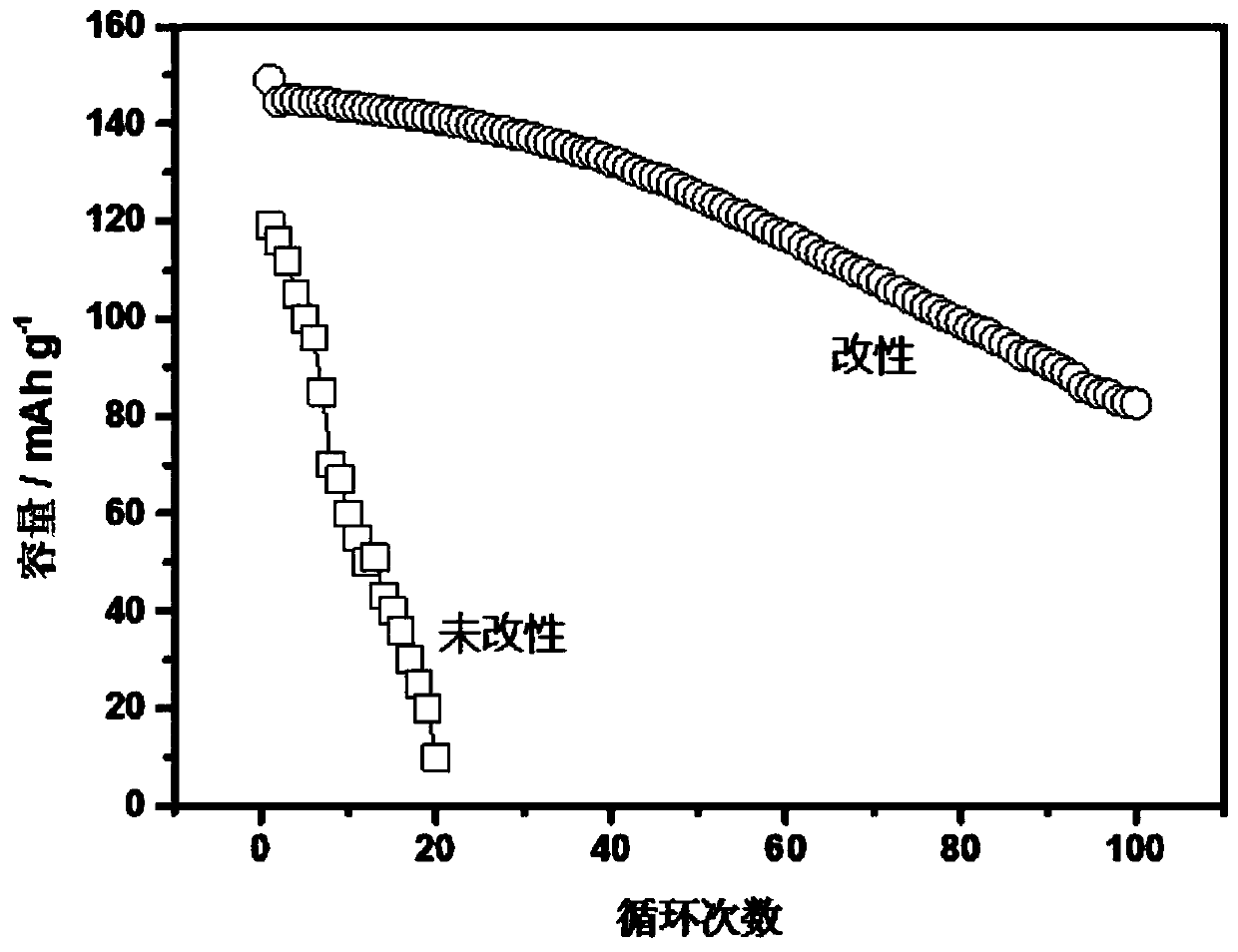

Embodiment 1

[0043] A method for preparing an all-solid electrolyte battery includes the following steps:

[0044] S1. Preparation of the solid electrolyte layer: drop concentrated nitric acid on the two surfaces of the well-fired and polished LLZO solid electrolyte sheet, treat them separately for 3 minutes, and then put the LLZO solid electrolyte sheet into absolute ethanol or isopropanol The surface is cleaned with a brush in a solvent, and then placed in an ultrasonic instrument for ultrasonic cleaning for 2 minutes, and finally an LLZO solid electrolyte ceramic sheet with a three-dimensional porous structure on both surfaces is obtained.

[0045] S2. Preparation of positive electrode slurry: ball mill the commercial ternary material (NMC532) to obtain nano-scale NMC532 ternary material, and then disperse it into a solution of α-terpineol and ethyl cellulose to form a flowing slurry.

[0046] S3. The combination of the positive electrode layer and the solid electrolyte layer: coating the prep...

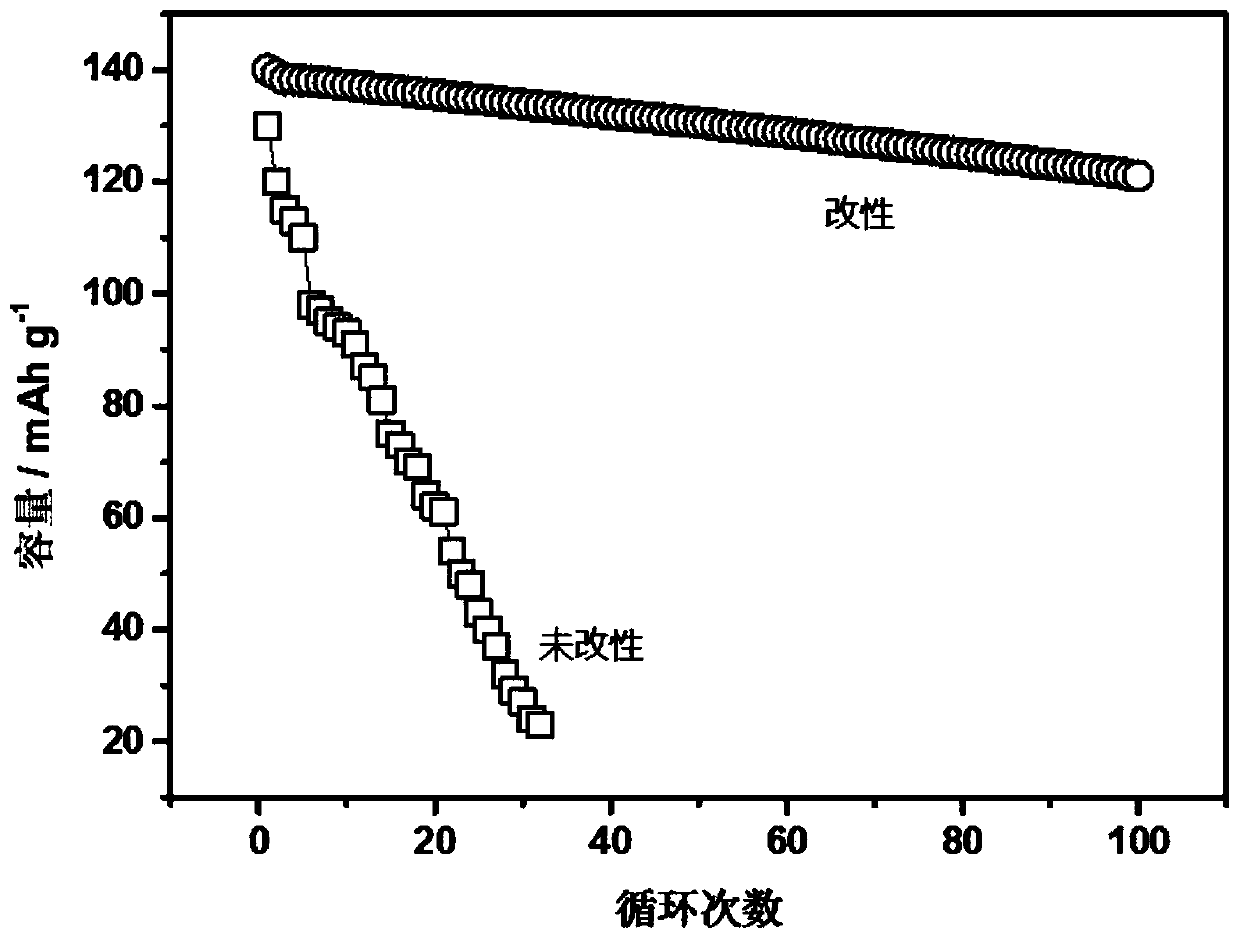

Embodiment 2

[0054] A method for preparing an all-solid electrolyte battery includes the following steps:

[0055] S1. Preparation of solid electrolyte layer: Add 50% citric acid solution dropwise to the two surfaces of the well-fired and polished LLZO solid electrolyte sheet, treat them for 5 minutes, and then place the LLZO solid electrolyte sheet on The surface was cleaned with a brush in anhydrous ethanol or isopropanol solvent, and then placed in an ultrasonic instrument for ultrasonic cleaning for 1 min. Finally, an LLZO solid electrolyte ceramic sheet with a three-dimensional porous structure on both surfaces was obtained.

[0056] S2. Preparation of positive electrode slurry: ball milling commercial lithium iron phosphate (LFP) to obtain nano-scale LFP, which is then dispersed in a solution of α-terpineol and ethyl cellulose to form a flowing slurry.

[0057] S3. Combination of the positive electrode layer and the solid electrolyte layer: coating the prepared positive electrode slurry on ...

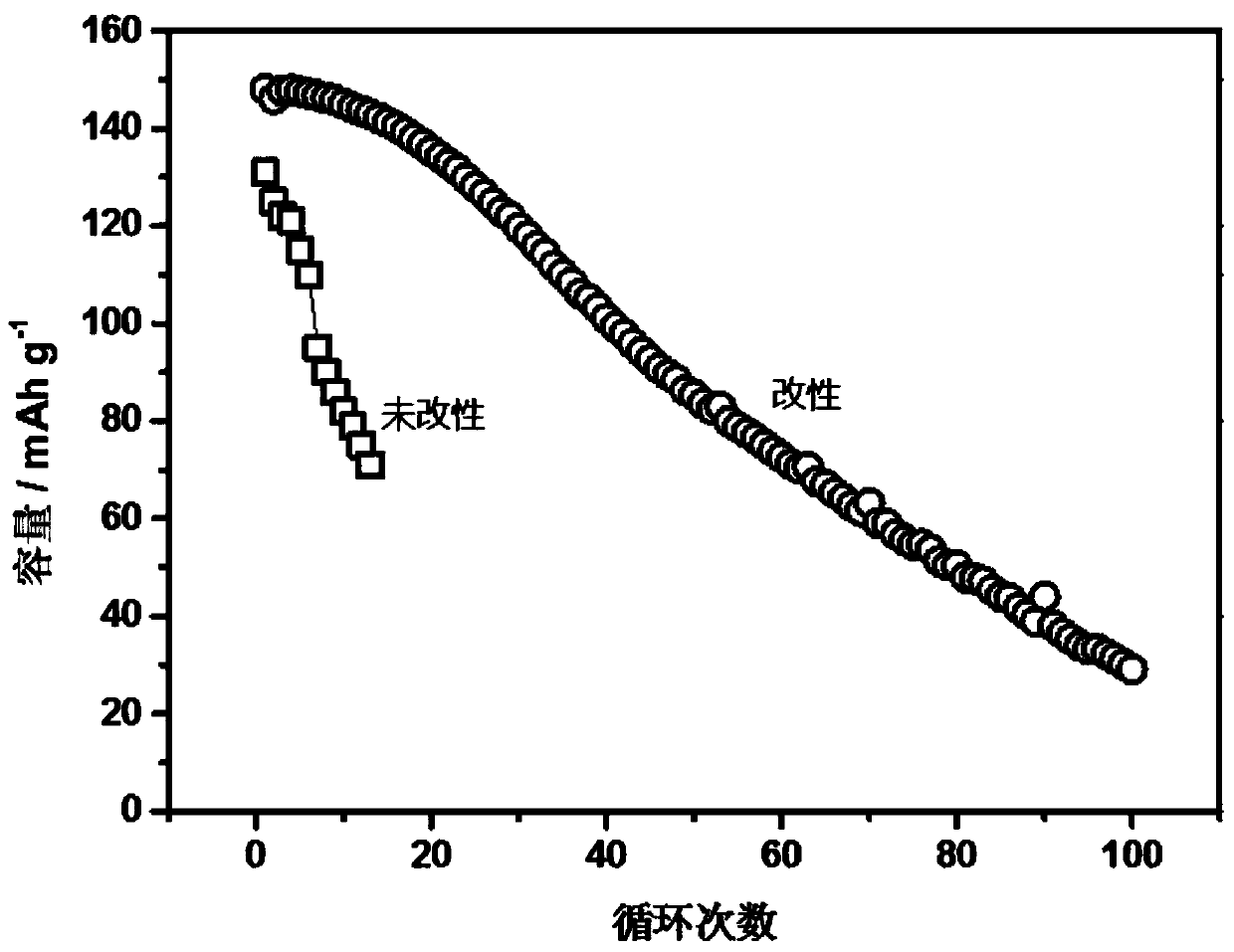

Embodiment 3

[0062] A method for preparing an all-solid electrolyte battery includes the following steps:

[0063] S1. Preparation of the solid electrolyte layer: drop a 50% mass fraction of citric acid solution onto the two surfaces of the well-fired and polished LLZO solid electrolyte sheet, treat them separately for 8 minutes, and then place the LLZO solid electrolyte sheet on The surface was cleaned with a brush in absolute ethanol or isopropanol solvent, and then placed in an ultrasonic instrument for ultrasonic cleaning for 3 minutes, and finally an LLZO solid electrolyte ceramic sheet with a three-dimensional porous structure on both surfaces was obtained.

[0064] S2. Preparation of positive electrode slurry: ball milling commercial lithium cobalt oxide (LCO) to obtain nano-scale LCO, which is then dispersed in a solution of α-terpineol and ethyl cellulose to form a flowing slurry.

[0065] S3. Combination of the positive electrode layer and the solid electrolyte layer: coating the prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com