Copper-iron bimetal loaded monolithic denitration catalyst, and preparation method and application thereof

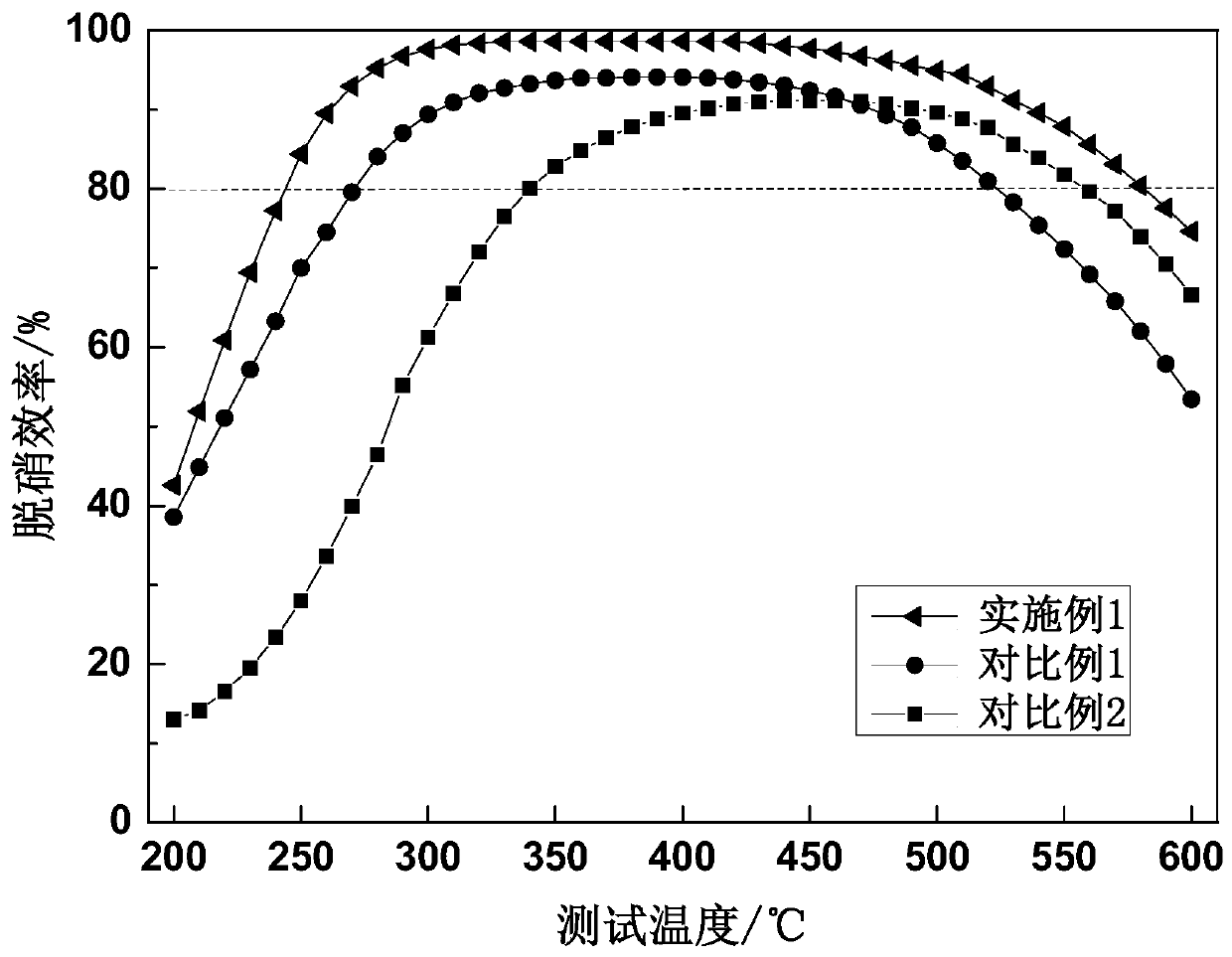

A denitration catalyst, copper-iron bimetal technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of copper-based molecular sieves, such as poor anti-sulfur ammonium salt poisoning ability and narrow active temperature range, etc. To achieve the effect of improving the resistance to ammonium sulfate poisoning, improving the denitration activity, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A copper-iron bimetallic supported monolithic denitrification catalyst, the components of which include, in parts by weight: 85 parts of cordierite ceramics, 18.6 parts of copper sulfate modified molecular sieves, and 37.1 parts of polyferric sulfate modified TiO 2 slurry, 34 parts aluminum sol and 4.3 parts PEG-400.

[0049] The preparation method of the above-mentioned copper-iron bimetallic supported monolithic denitration catalyst has the following steps:

[0050] (1) Preparation of copper sulfate modified molecular sieve

[0051] Add 3.3 parts of copper sulfate to 278.6 parts of deionized water for dissolution, then add 27.9 parts of ZSM-5 molecular sieve, keep it at 80°C for 8 hours, filter, dry, and roast at 600°C for 3 hours;

[0052] (2) Carrier pretreatment

[0053] Soak 85 parts of cordierite ceramics in sulfuric acid solution for 8 hours, rinse with deionized water until neutral, and dry;

[0054] (3) Coating TiO modified by polyferric sulfate 2 slurry ...

Embodiment 2

[0059] A copper-iron bimetallic supported monolithic denitration catalyst, the components of which include in parts by weight: 85 parts of cordierite ceramics, 17.7 parts of copper sulfate modified molecular sieves, and 28.4 parts of TiO modified by polyferric chloride 2 Slurry, 44 parts aluminum sol and 4.2 parts PEG-4000.

[0060] The preparation method of the above-mentioned copper-iron bimetallic supported monolithic denitration catalyst has the following steps:

[0061] (1) Preparation of copper sulfate modified molecular sieve

[0062] Add 4.7 parts of copper sulfate to 264.8 parts of deionized water for dissolution, then add 26.5 parts of Beta molecular sieves, heat at 90°C for 4 hours, filter, dry, and roast at 550°C for 5 hours;

[0063] (2) Carrier pretreatment

[0064] Soak 85 parts of cordierite ceramics in acetic acid solution for 8 hours, rinse with deionized water until neutral, and dry;

[0065] (3) Coating copper sulfate modified molecular sieve

[0066] A...

Embodiment 3

[0070] A copper-iron bimetallic supported monolithic denitration catalyst, the components of which include, in parts by weight: 78 parts of cordierite ceramics, 16.7 parts of copper sulfate modified molecular sieves, 22.4 parts of polysilicate ferric sulfate modified TiO 2 Slurry, 51 parts aluminum sol and 3.8 parts PEG-4000.

[0071] The preparation method of the above-mentioned copper-iron bimetallic supported monolithic denitration catalyst has the following steps:

[0072] (1) Preparation of copper sulfate modified molecular sieve

[0073] Add 5.9 parts of copper sulfate to 250.1 parts of deionized water for dissolution, then add 25.0 parts of SSZ-13 molecular sieves, heat at 100°C for 2 hours, filter, dry, and roast at 500°C for 6 hours;

[0074] (2) Carrier pretreatment

[0075] Soak 78 parts of cordierite ceramics in oxalic acid solution for 24 hours, rinse with deionized water until neutral, and dry;

[0076] (3) Coating polysilicate iron sulfate modified TiO 2 slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com