A kind of preparation method of inorganic flocculant based on tuff and aluminum ash

An inorganic flocculant and tuff technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water treatment parameter control, etc., can solve the problems of low pollutant removal rate and poor separation effect of flocculant water body, etc., to achieve The effect of low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

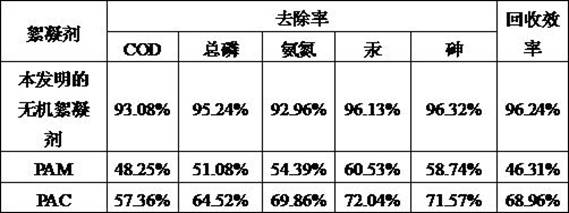

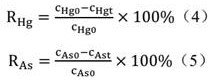

[0022] Effects of the mass ratio of sodium phosphate and tuff on the removal of COD, total phosphorus, ammonia nitrogen, mercury and arsenic in landfill leachate by the prepared inorganic flocculant

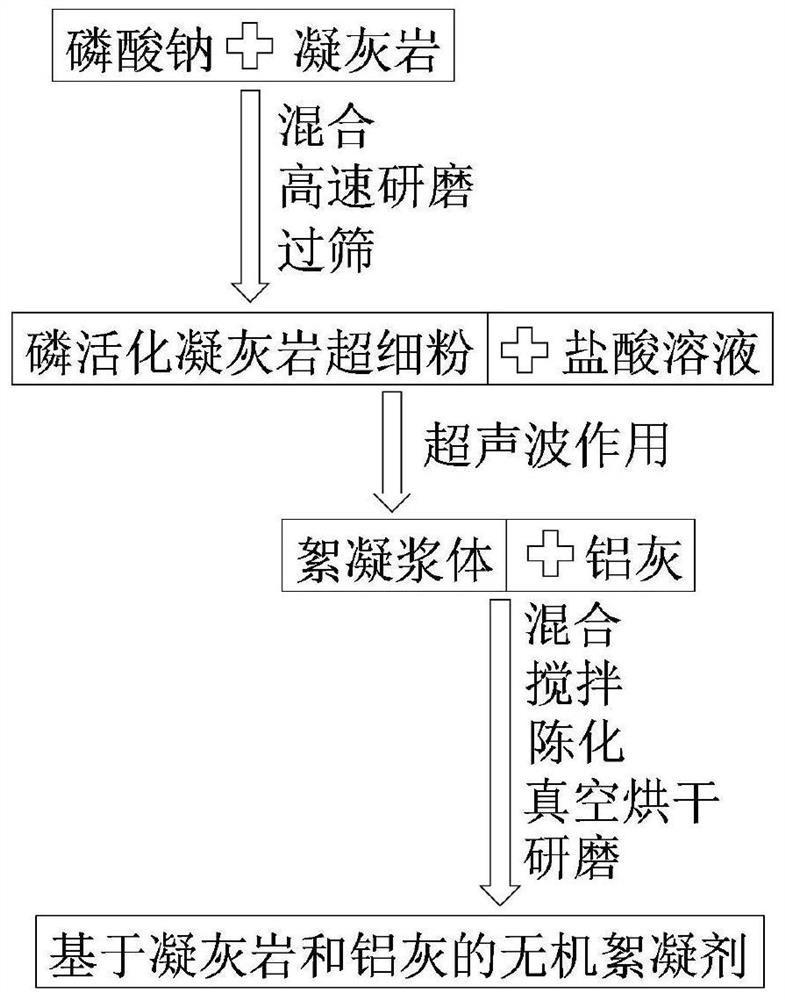

[0023] Preparation of inorganic flocculants based on tuff and aluminum ash: as figure 1 As shown, according to the mass ratio of sodium phosphate and tuff 2.5:100, 3.5:100, 4.5:100, 5:100, 10:100, 15:100, 15.5:100, 16.5:100, 17.5:100 respectively weigh sodium phosphate Mix with tuff, grind at 2000rpm at a high speed for 30min, and pass through a 2000 mesh sieve to obtain phosphorus-activated tuff superfine powder; mix concentrated hydrochloric acid and water to prepare 5mol / L hydrochloric acid solution, according to the solid-liquid ratio of 1:1 (mg:mL ) Add phosphorus-activated tuff superfine powder into hydrochloric acid solution, and apply ultrasonic waves for 6 hours under the condition of 60°C and 400W output power to obtain flocculation slurry; weigh aluminum ash according ...

Embodiment 2

[0037] Effect of concentration of hydrochloric acid solution on the removal of COD, total phosphorus, ammonia nitrogen, mercury and arsenic in landfill leachate by the prepared inorganic flocculant

[0038] Preparation of inorganic flocculant based on tuff aluminum ash: take sodium phosphate and tuff according to the mass ratio of sodium phosphate and tuff 15:100, mix, grind for 45min under the condition of 6000rpm high speed, and pass through a 5000 mesh sieve to obtain phosphorus-activated tuff super Fine powder; mixed with concentrated hydrochloric acid and water to prepare 2.5mol / L, 3.5 mol / L, 4.5 mol / L, 5 mol / L, 10 mol / L, 15mol / L, 15.5 mol / L, 16.5 mol / L, 17.5 mol / L hydrochloric acid solution; according to the solid-to-liquid ratio of 1:1.5 (mg:mL), add phosphorous-activated tuff superfine powder into the hydrochloric acid solution, and apply ultrasonic waves for 9 hours at 80°C and 800W output power to obtain flocculation slurry; Weigh aluminum ash and flocculation slurry...

Embodiment 3

[0044] Effects of the mass ratio of aluminum ash and flocculation slurry on the removal of COD, total phosphorus, ammonia nitrogen, mercury and arsenic in landfill leachate by the prepared inorganic flocculant

[0045] The preparation of the inorganic flocculant based on tuff and aluminum ash: take sodium phosphate and tuff by weighing sodium phosphate and tuff mass ratio 15:100, mix, grind 60min under the condition of 10000rpm high speed, pass 8000 mesh sieves, obtain phosphorus-activated tuff super Fine powder; mix concentrated hydrochloric acid and water to prepare 15mol / L hydrochloric acid solution, add phosphorus-activated tuff ultra-fine powder to the hydrochloric acid solution according to the solid-to-liquid ratio of 1:2 (mg:mL), under the conditions of 100°C temperature and 1200W output power Ultrasound for 12 hours to obtain flocculation slurry; according to the mass ratio of aluminum ash and flocculation slurry 1:100, 1.5:100, 1.75:100, 2:100, 4:100, 6:100, 6.5:100, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com