High-strength low-carbon low-alloy steel for building and preparing process thereof

A low-alloy steel and preparation process technology, applied in the field of alloy steel, can solve the problems of poor strength and toughness, and achieve the effects of reducing scarce precious metals, reducing production costs, and uniform structure without defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

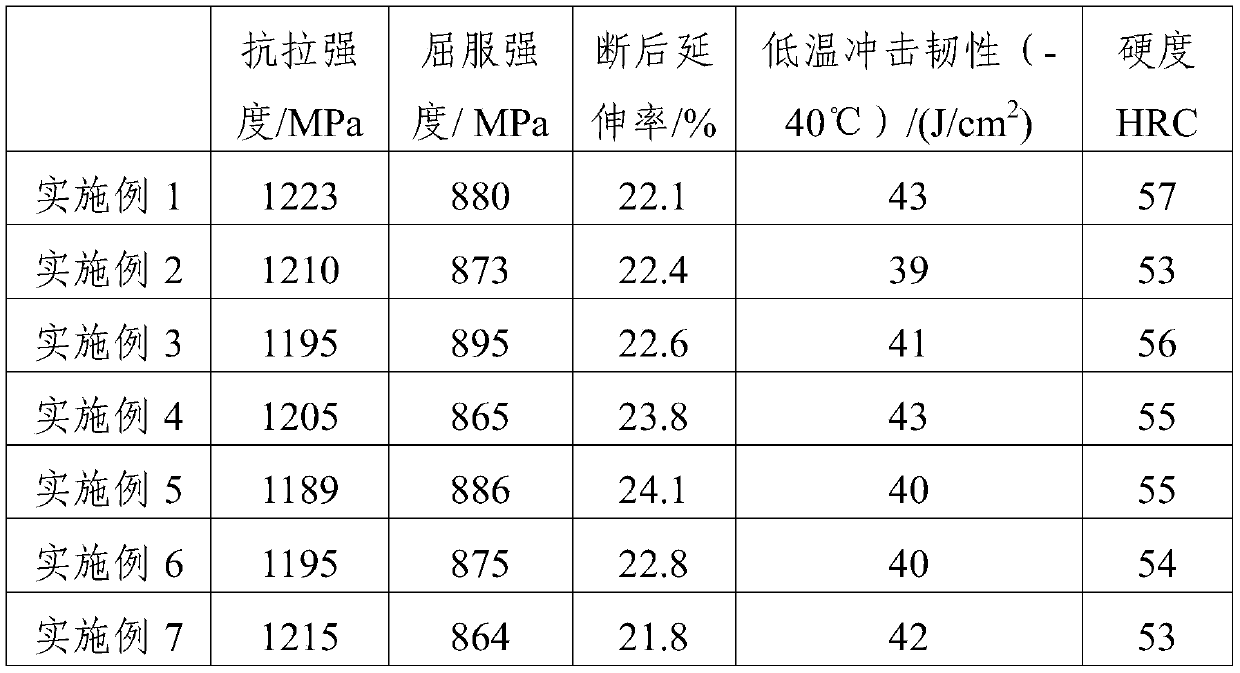

Examples

Embodiment 1

[0039] A high-strength low-carbon low-alloy steel for construction, the weight percentage of each element composition is: C: 0.078%, Si: 0.13%, Mn: 0.95%, Ni: 0.72%, B: 0.019%, Zr: 0.15% , Nb: 0.08%, Re: 0.0025%, P≤0.006%, S≤0.01%, the balance is Fe and unavoidable impurities.

[0040] The preparation process of the above-mentioned high-strength low-carbon low-alloy steel for construction comprises the following steps:

[0041] (1) After batching, add each raw material into an intermediate frequency induction furnace for smelting, heat to 1590 ° C, keep warm for 10 minutes, add 0.06% of the total amount of raw materials into nano-zirconium carbide, and keep warm for 20 minutes;

[0042] (2) Deoxidize molten steel with 0.05% silicon-calcium powder, then insert aluminum wire for final deoxidation, adjust the temperature of molten steel to 1630°C, and release it from the furnace; put a modifier at the bottom of the ladle, and the amount of modifier added is the total amount of molt...

Embodiment 2

[0049] A high-strength low-carbon low-alloy steel for construction, the weight percentage of each element composition is: C: 0.09%, Si: 0.16%, Mn: 0.7%, Ni: 0.81%, B: 0.013%, Zr: 0.14% , Nb: 0.07%, Re: 0.0018%, P≤0.006%, S≤0.01%, the balance is Fe and unavoidable impurities.

[0050] The preparation process of the above-mentioned high-strength low-carbon low-alloy steel for construction comprises the following steps:

[0051] (1) After batching, add each raw material into an intermediate frequency induction furnace for smelting, heat to 1600°C, keep warm for 10 minutes, add 0.07% of the total amount of raw materials into nano-zirconium carbide, and keep warm for 20 minutes;

[0052] (2) Deoxidize molten steel with 0.05% silicon-calcium powder, then insert aluminum wire for final deoxidation, adjust the temperature of molten steel to 1620°C, and release it from the furnace; put a modifier at the bottom of the ladle, and the amount of modifier added is the total amount of molten...

Embodiment 3

[0059] A high-strength low-carbon low-alloy steel for construction, the weight percentage of each element composition is: C: 0.11%, Si: 0.13%, Mn: 0.7%, Ni: 0.6%, B: 0.021%, Zr: 0.16% , Nb: 0.07%, Re: 0.0018%, P≤0.006%, S≤0.01%, the balance is Fe and unavoidable impurities.

[0060] The preparation process of the above-mentioned high-strength low-carbon low-alloy steel for construction comprises the following steps:

[0061] (1) After batching, add each raw material into an intermediate frequency induction furnace for smelting, heat to 1580 ° C, keep warm for 10 minutes, add 0.05% of the total amount of raw materials into nano-zirconium carbide, and keep warm for 18 minutes;

[0062] (2) Deoxidize molten steel with 0.05% silicon-calcium powder, then insert aluminum wire for final deoxidation, adjust the temperature of molten steel to 1620°C, and release it from the furnace; put a modifier at the bottom of the ladle, and the amount of modifier added is the total amount of molte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com