Nickel-cobalt-manganese composite hydroxide added with hexavalent elements and preparation method of nickel-cobalt-manganese composite hydroxide

A technology of composite hydroxide and hexavalent elements, which is applied in the field of nickel-cobalt-manganese composite hydroxide and its preparation, can solve the problems of uneven doping of hexavalent elements and easily broken particles, and achieve crystal lattice stability and element distribution Uniform, safety-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

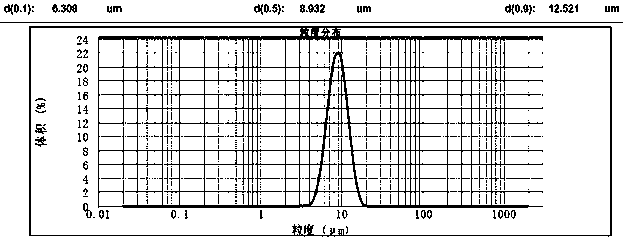

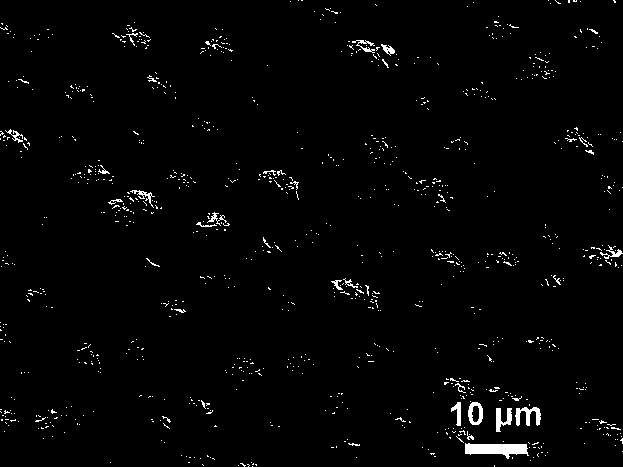

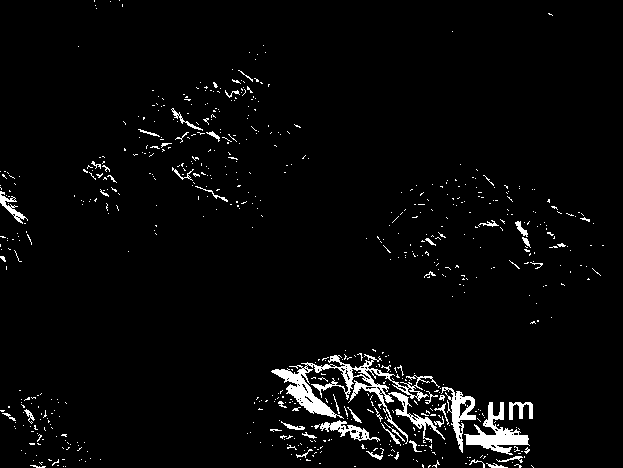

[0046] The chemical formula is Ni 0.6 co 0.2 mn 0.2 (OH) 1.98 (MoO 4 ) 0.01 , D50=8.9μm Preparation method of nickel-cobalt-manganese composite hydroxide with hexavalent molybdenum added:

[0047] Step 1, according to the molar ratio of nickel, cobalt, manganese and hexavalent molybdenum in the nickel-cobalt-manganese hydroxide that needs to add hexavalent molybdenum, that is, 0.6:0.2:0.2:0.01, select nickel sulfate, cobalt sulfate, sulfuric acid Manganese and molybdenum trioxide are raw materials;

[0048] Step 2, nickel sulfate, cobalt sulfate, manganese sulfate and pure water selected in step 1 are mixed with a mixed salt solution whose total metal ion concentration is 2.0mol / L;

[0049] Step 3, preparation concentration is 5.0 mol / L sodium hydroxide solution;

[0050] Step 4, dissolving the molybdenum trioxide selected in step 1 into the sodium hydroxide solution prepared in step 3 until clarification without precipitation, obtaining a sodium hydroxide solution cont...

Embodiment 2

[0060] The chemical formula is Ni 0.34 co 0.33 mn 0.33 (OH) 1.994 (WO 4 ) 0.003 , D50=2.6μm Preparation method of nickel-cobalt-manganese composite hydroxide with hexavalent tungsten added:

[0061] Step 1, according to the molar ratio of nickel, cobalt, manganese and hexavalent tungsten element in the nickel-cobalt-manganese hydroxide to which hexavalent tungsten element needs to be added, that is, 0.34:0.33:0.33:0.003, nickel sulfate, cobalt sulfate, sulfuric acid Manganese and ammonium tungstate are raw materials;

[0062] Step 2, nickel sulfate, cobalt sulfate, manganese sulfate and pure water selected in step 1 are mixed with a mixed salt solution whose total metal ion concentration is 2.0mol / L;

[0063] Step 3, preparation concentration is 10.0 mol / L sodium hydroxide solution;

[0064] Step 4, dissolving the ammonium tungstate selected in step 1 into the sodium hydroxide solution prepared in step 3 until it is clear and free of precipitation, to obtain a sodium hy...

Embodiment 3

[0074] The chemical formula is Ni 0.6 co 0.2 mn 0.2 (OH) 1.98 (WO 4 ) 0.01 , D50=8.9μm Preparation method of nickel-cobalt-manganese composite hydroxide with hexavalent tungsten added:

[0075] Step 1, according to the molar ratio of nickel, cobalt, manganese and hexavalent tungsten element in the nickel-cobalt-manganese hydroxide to which hexavalent tungsten element needs to be added, that is, 0.6:0.2:0.2:0.01, nickel sulfate, cobalt sulfate, sulfuric acid Manganese and ammonium tungstate are raw materials;

[0076] Step 2, nickel sulfate, cobalt sulfate, manganese sulfate and pure water selected in step 1 are mixed with a mixed salt solution whose total metal ion concentration is 2.0mol / L;

[0077] Step 3, preparation concentration is 5.0 mol / L sodium hydroxide solution;

[0078] Step 4, dissolving the ammonium tungstate selected in step 1 into the sodium hydroxide solution prepared in step 3 until it is clear and free of precipitation, to obtain a sodium hydroxide so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com