Dye solvent heat-sensitive MOFs photocatalyst, preparation method and application thereof

A photocatalyst and solvothermal technology, which is applied in physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, chemical instruments and methods, etc., can solve the problems of poor visible light absorption capacity and improve visible light catalysis Effects of hydrogen production activity, improved stability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

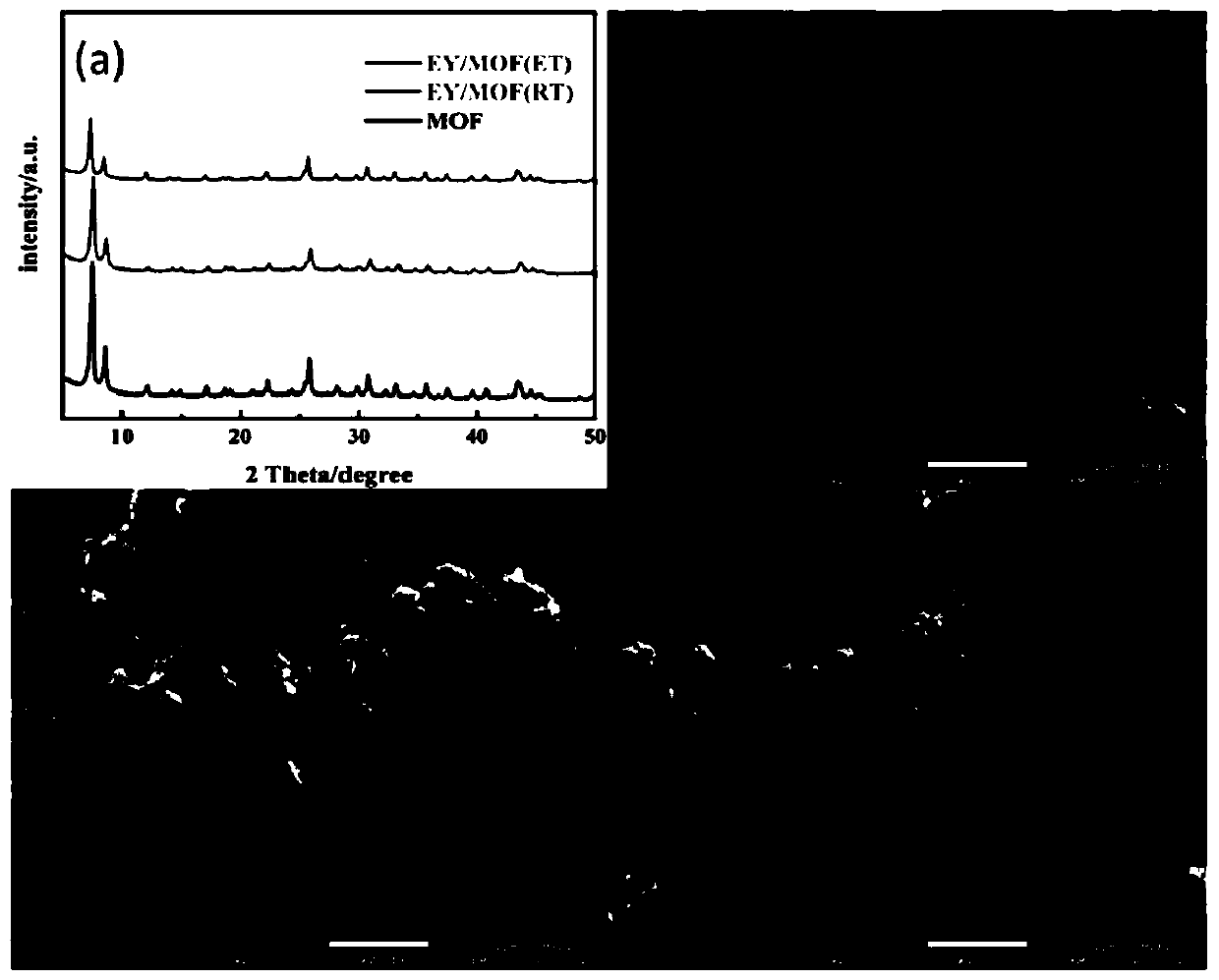

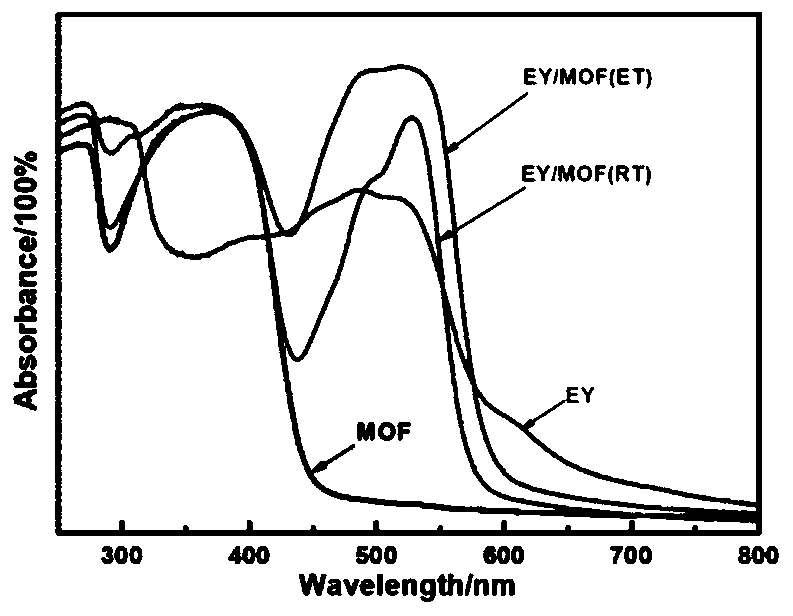

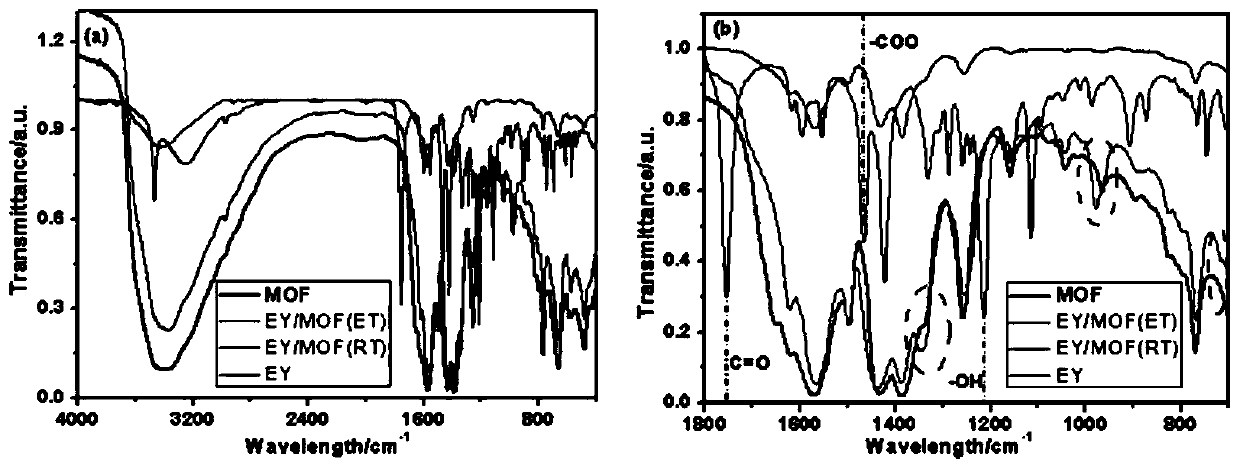

[0028] A kind of preparation method of dye solvent heat-sensitized MOFs photocatalyst of the present invention, the steps are as follows:

[0029] Step 1: Synthesis of MOFs (UiO-66-NH 2 For example): add 0.2-0.5g zirconium chloride hexahydrate and 10-50mL N,N-dimethylformamide (DMF) polytetrafluoroethylene hydrothermal kettle lining, ultrasonic 20min zirconium chloride completely After dissolving, add 1-8mL concentrated hydrochloric acid dropwise, then add 0.1-0.5g 2-aminoterephthalic acid (H 2 APTA) and 10-30mL DMF, continue to sonicate for 20min. Next, transfer the lining of the hydrothermal kettle to the outer shell of the stainless steel hydrothermal kettle, seal it, and keep it in an oven at 60-120° C. for 12-48 hours. After the reaction was completed, the obtained pale yellow suspension was centrifuged, and the precipitate was washed 3 times with DMF and 3 times with methanol. The yellow sample obtained by centrifugation was dried at 85°C to obtain UiO-66-NH 2 (This ...

Embodiment 1

[0034] Embodiment 1 is the standard preparation method that the present invention uses

[0035] Step 1: Add 0.268g of zirconium chloride hexahydrate to the inner lining of 20mL DMF polytetrafluoroethylene hydrothermal kettle, ultrasonically dissolve the zirconium chloride for 20 minutes, add 2mL of concentrated hydrochloric acid dropwise, and then add 0.250g of 2-amino p- Phthalic acid (H 2 APTA) and 10mL DMF, continue to sonicate for 20min. Next, transfer the inner lining of the hydrothermal kettle to the outer shell of the stainless steel hydrothermal kettle, seal it, and keep it in an oven at 80°C for 24 hours. After the reaction was completed, the obtained pale yellow suspension was centrifuged, and the precipitate was washed 3 times with DMF and 3 times with methanol. The yellow sample obtained by centrifugation was dried at 85°C to obtain UiO-66-NH 2 .

[0036] Step 2: Add EY and MOF to the lining of a hydrothermal kettle containing 20mL of ethanol according to the m...

Embodiment 2

[0038] Embodiment 2 is the preparation method that has changed concentrated hydrochloric acid amount

[0039] Step 1: Add 0.268g of zirconium chloride hexahydrate to the lining of 20mL DMF polytetrafluoroethylene hydrothermal kettle, ultrasonically dissolve the zirconium chloride for 20min, add 1mL of concentrated hydrochloric acid dropwise, and then add 0.250g of 2-amino p- Phthalic acid and 10mL DMF, continue to sonicate for 20min. Next, transfer the inner lining of the hydrothermal kettle to the outer shell of the stainless steel hydrothermal kettle, seal it, and keep it in an oven at 80°C for 24 hours. After the reaction was completed, the obtained pale yellow suspension was centrifuged, and the precipitate was washed 3 times with DMF and 3 times with methanol. The yellow sample obtained by centrifugation was dried at 85°C to obtain UiO-66-NH 2 .

[0040] Step 2: Add EY and MOF to the lining of a hydrothermal kettle containing 20mL of ethanol according to the mass ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com