Novel spherical powder and preparation method thereof

A spherical powder, a new type of technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of increasing pore content and microcracks in parts, difficult 3D printing technology, high powder preparation cost, etc., to achieve regular particle shape, Good sphericity and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

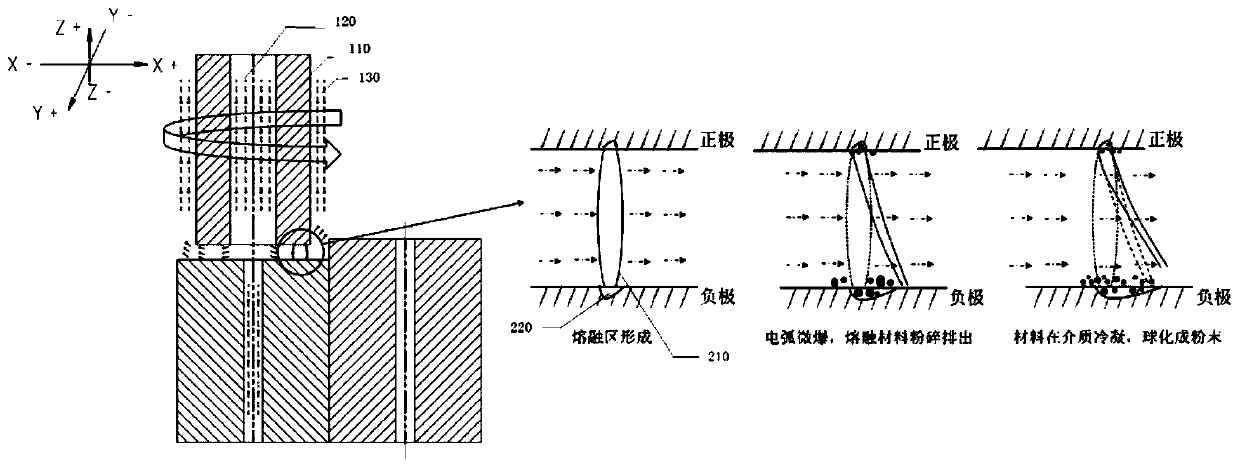

[0016] A kind of preparation method of novel spherical powder, comprises the following steps:

[0017] Place the electrode and the workpiece on the two poles of the power supply, adjust the discharge gap between the electrode and the workpiece through the motion control system to generate arc plasma, and when the arc plasma acts on the electrode and the surface of the workpiece, the electrode and the surface of the workpiece are promoted Melting, forming a melting zone, at the same time, introducing a fluid medium in the discharge gap, by controlling the flow rate of the fluid medium, and the relative rotational speed of the electrode or the workpiece, the arc plasma working form is changed, and the melting zone is promoted generating tiny explosions, pulverizing and throwing away the material located in the melting zone, condensing the pulverized molten material in the fluid medium, and collecting the condensed fine spherical powder;

[0018] The electrode is provided with a ...

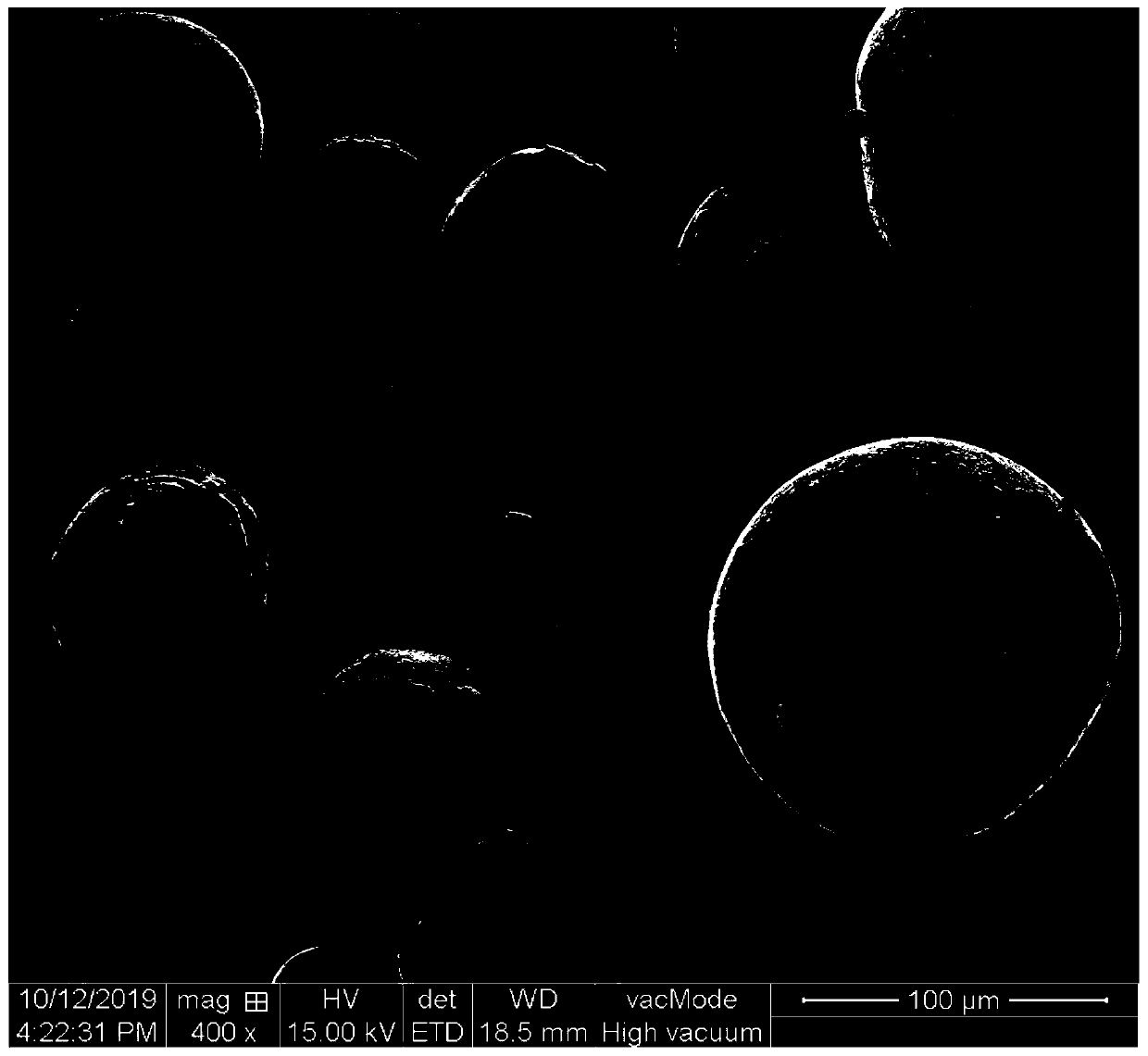

Embodiment 1

[0039] The present embodiment provides a kind of preparation method of novel spherical powder, comprises the following steps:

[0040] Take block 304 stainless steel as the workpiece, the size is 100mm*100mm*20mm, after cleaning and decontaminating it, connect it to the cathode of the power supply. Connect the graphite electrode provided with a single tube to the positive pole of the power supply. The distance between the discharge end of the electrode and the workpiece is 0.5 mm. The multiple tubes refer to several channel tubes located between the electrode assemblies, and the outlets of the channel tubes face the block 304 stainless steel.

[0041] The power supply parameters are set as follows: the gap voltage is 45V-55V, the discharge current is 500A, the pulse width is 2000μs, and the pulse interval is 200μs, the power supply is turned on, and the rotation speed of the electrode is controlled to be 5000r / min. Simultaneously, feed distilled water in several said channel...

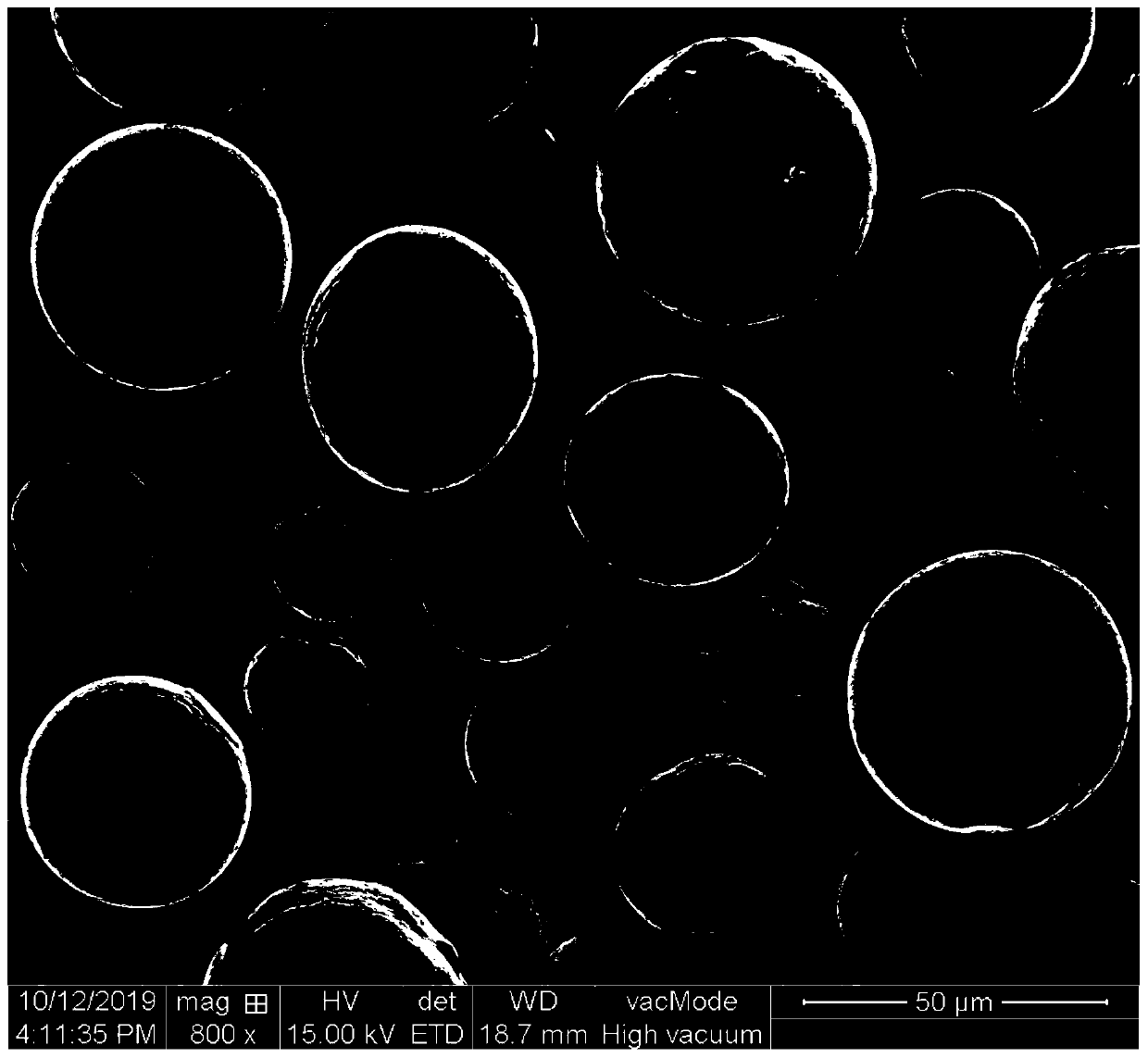

Embodiment 2

[0044] The present embodiment provides a kind of preparation method of novel spherical powder, comprises the following steps:

[0045] The rod-shaped TC4 (titanium alloy) is used as the workpiece for processing, and the outer diameter is Inner diameter is The length is 100mm. After cleaning and decontaminating it, connect it to the anode of the power supply. Connect the TC4 electrode to the cathode of the power supply, the distance between the discharge end of the electrode and the workpiece is 1mm, the rod-shaped TC4 is provided with a channel tube, and the outlet of the channel tube faces the TC4 electrode.

[0046] The power supply parameters are set as follows: gap voltage 45V-55V, discharge current 500A, pulse width 2000μs, pulse interval 200μs, start the power supply, and control the rotating speed of the tube rotating electrode to 3000r / min. Simultaneously, distilled water is passed into the passage pipe and the passage pipe, and when passing through, its flow rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com