Preparation method for linagliptin and intermediate thereof

An intermediate and solid technology, applied in the field of preparation of linagliptin and its intermediates, can solve the problems of difficulty in filtration or centrifugal drying, genotoxic impurities, bromide residues, etc., and achieves reduction of time and labor costs, and purity. Improve and reduce the effect of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Preparation of linagliptin intermediate

[0035] a) At room temperature, add the compound 8-bromo-7-(2-butynyl)-3,7-dihydro-3-methyl-1-[(4-methyl-2-quinazole) into the reaction flask Phenyl)methyl]-1H-purine-2,6-dione (100.00g, 220.6mmol), (R)-3-tert-butoxycarbonylaminopiperidine (57.50g, 287.0mmol), potassium carbonate (122.00g , 883.0mmol), acetonitrile 475ml, dimethyl sulfoxide 25ml, stirred and heated up to 84-86°C, kept stirring for about 20 hours.

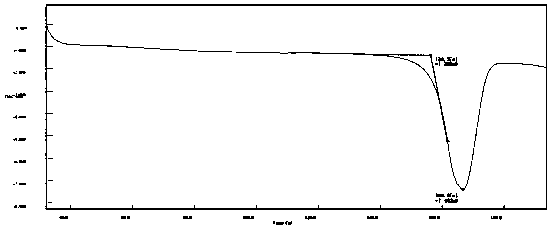

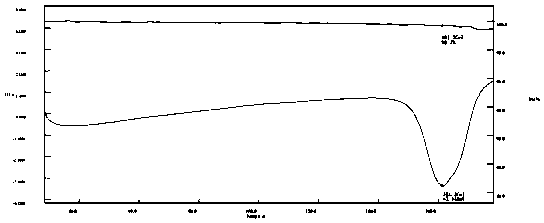

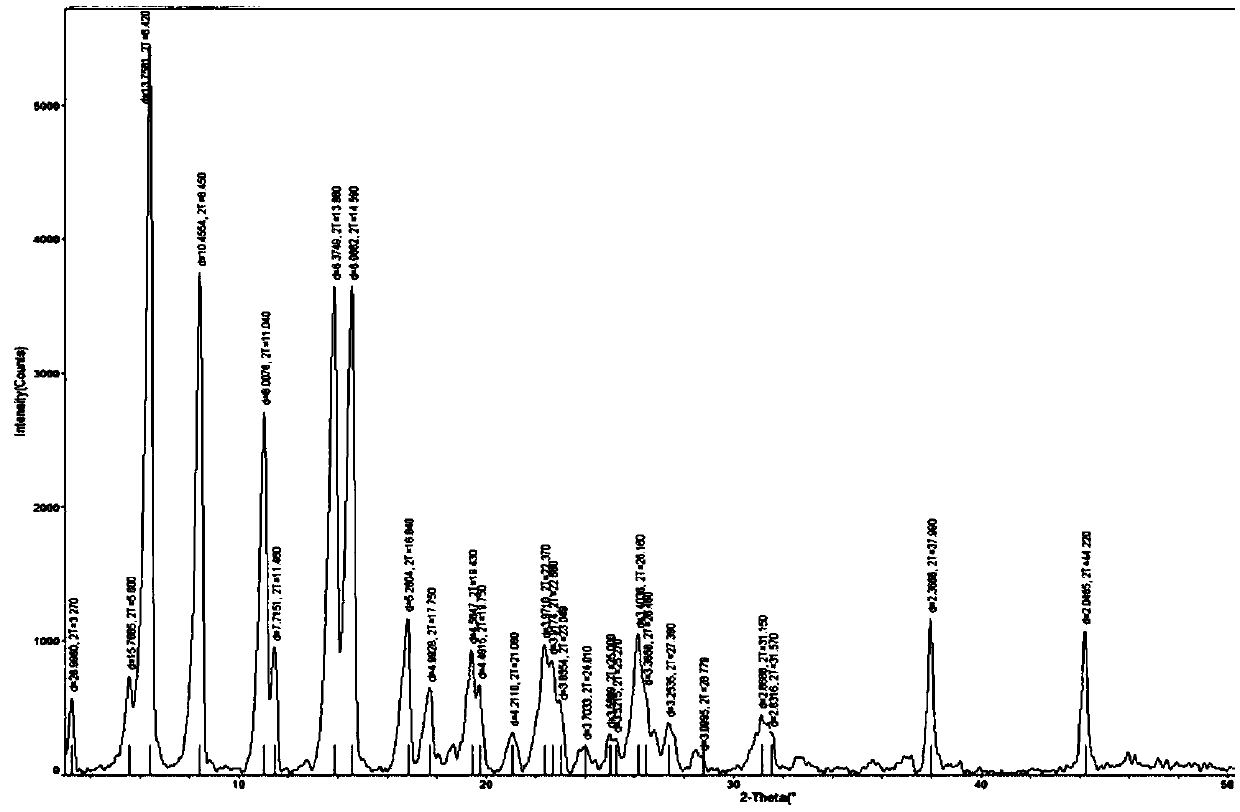

[0036] b) After the reaction, add 750ml of purified water dropwise to the reaction bottle. After the dropwise addition, stir to dissolve, control the temperature at 65-67°C, keep stirring, and wait for white solid to precipitate, then keep stirring at 65-67°C for 2 hour, cooled to about 25°C, stirred for 1 hour, filtered, and after the filter cake was drained, rinsed and drained with 500ml of purified water to obtain a white crystalline powder solid product D (120.40g, 210.2mmol), yield 95.30% , 99.935% purity. T...

Embodiment 2

[0045] Steps 1)-2) of Example 1 were used to prepare linagliptin, the difference being that the heat preservation and crystallization temperature of step b) in step 1) was 56-58°C. After step 1), a white crystalline powder solid product D (120.31 g, 210.1 mmol) was obtained with a yield of 95.23% and a purity of 99.877%. After step 2), a white solid E (35.93 g, 76.0 mmol) was obtained with a yield of 87.09% and a purity of 99.905%.

[0046] Example 2(b)

[0047] Steps 1)-2) of Example 1 were used to prepare linagliptin, the difference being that the heat preservation and crystallization temperature of step b) in step 1) was 72-74°C. After step 1), a white crystalline powder solid product D (120.29 g, 210.1 mmol) was obtained with a yield of 95.22% and a purity of 99.930%. After step 2), a white solid E (35.91 g, 76.00 mmol) was obtained with a yield of 87.04% and a purity of 99.923%.

Embodiment 3

[0049] Steps 1)-2) of Example 1 were used to prepare linagliptin, the difference being that the solvent used in step a) in step 1) was 475ml of acetonitrile, 25ml of N,N-dimethylformamide, Reaction time 18 hours. After step 1), a white crystalline powder solid product D (120.16 g, 209.8 mmol) was obtained with a yield of 95.11% and a purity of 99.896%. After step 2), a white solid E (36.02 g, 76.2 mmol) was obtained with a yield of 87.30% and a purity of 99.911%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com