Production process for separation and purification of beta-glucan in oat bran based on ultrafiltration membrane technology

An oat bran, separation and purification technology, applied in membrane technology, semi-permeable membrane separation, ultrafiltration and other directions, can solve the problems of industrial production and large-scale clinical application limitations, increase production costs, and long production cycles, and achieve single High separation efficiency, easy extraction and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

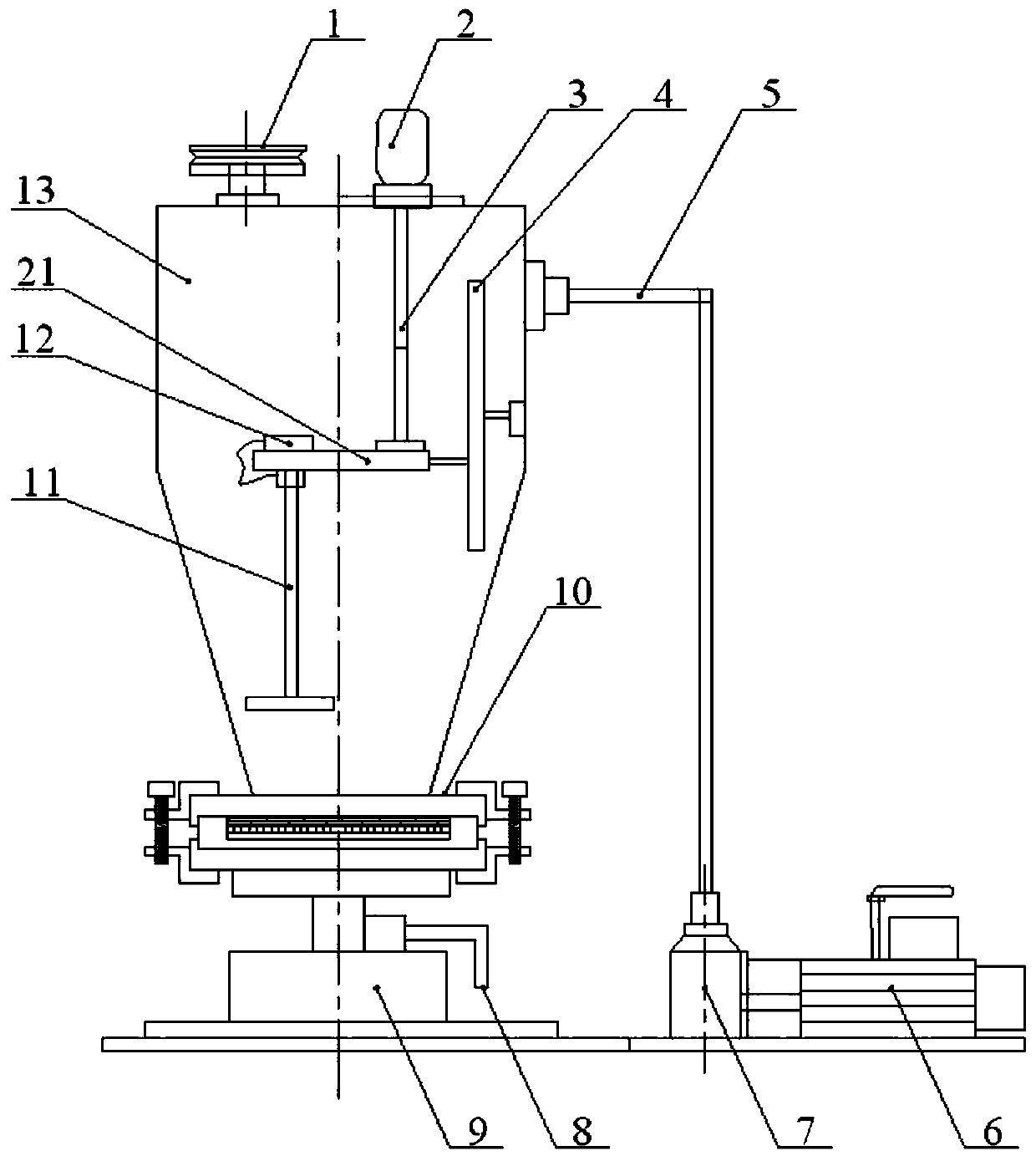

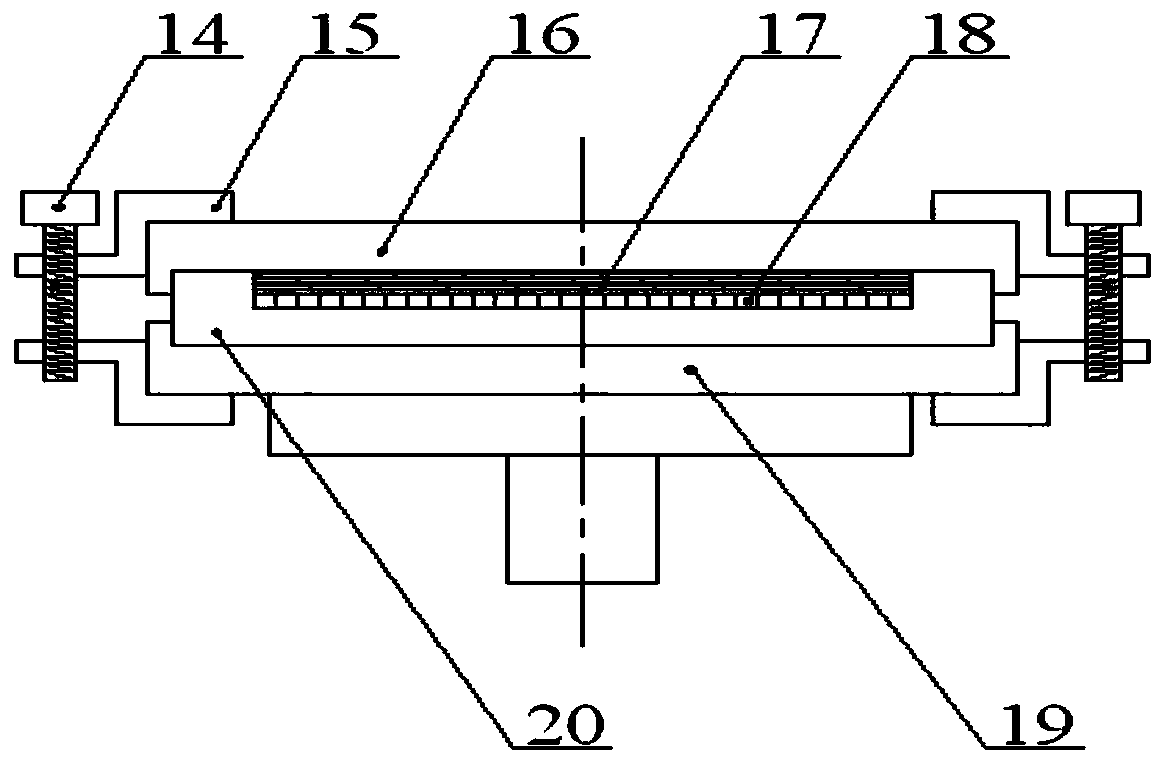

[0030] A production process for the separation and purification of β-glucan in oat bran based on ultrafiltration membrane technology, oat bran crushing → β-glucan extraction → preparation of β-glucan aqueous solution → microfiltration → ultrafiltration → freeze-drying → β-glucan finished product, the specific process steps are as follows:

[0031] (1) Oat bran pulverization: screen bran after raw oat pulverization, mesh 60-120;

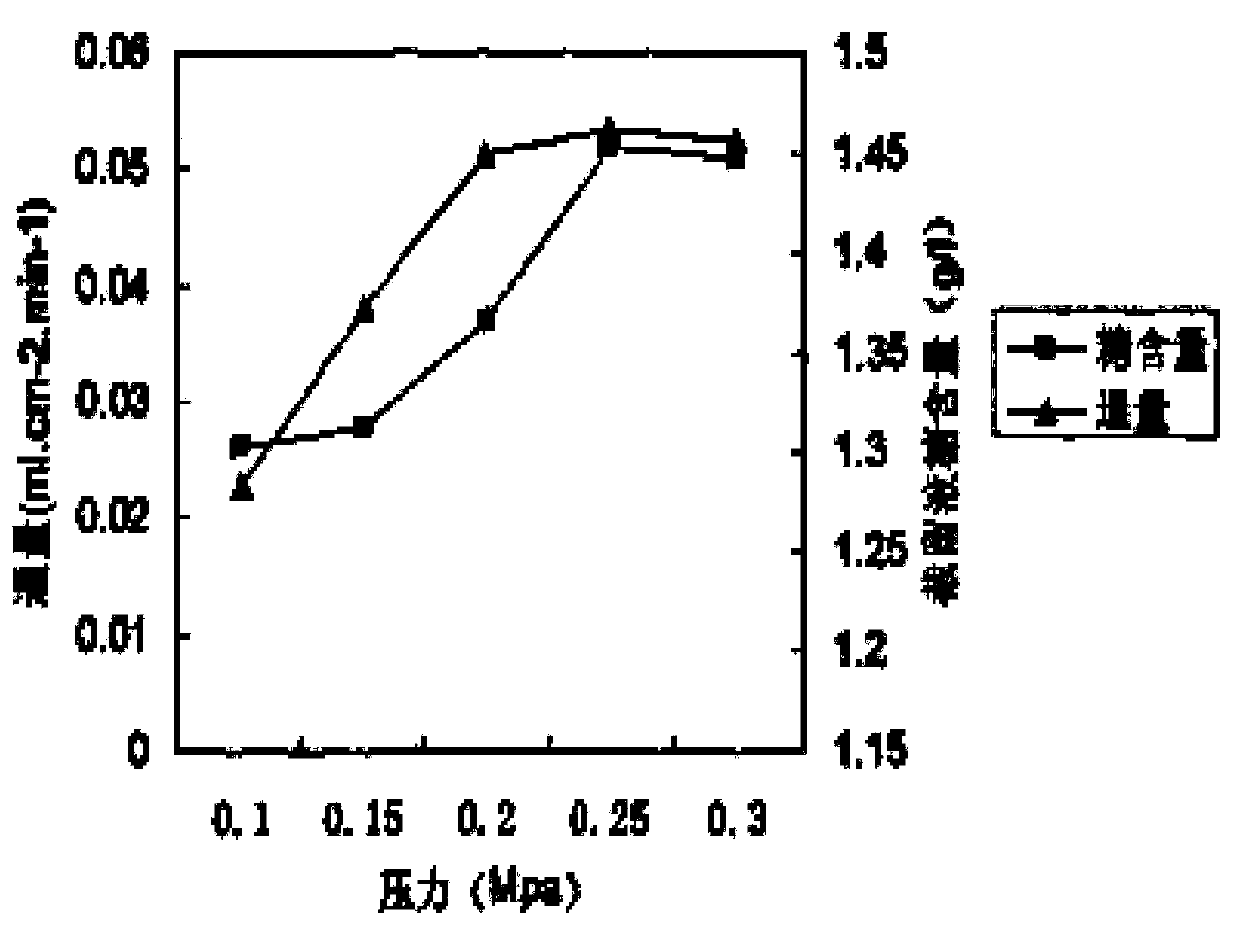

[0032] (2) Extraction of β-glucan: Take a buffer solution with pH 4-6 and containing α-amylase, the ratio of bran to liquid is 1:80-100, the extraction temperature is 80-90°C, extract for 5-6 hours, and cool to room temperature , adjusting the pH to 6-8, centrifuging to take the supernatant, alcohol precipitation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com