Method for reducing proportion of succinic acid fermentation by-products of actinobacillus succinogenes

A technology of actinomycetes and succinic acid, which is applied in the field of fermentation engineering, can solve the problems of high proportion of by-products and reduce the proportion of by-products of succinic acid fermentation, and achieve the effects of low cost, low content and low accumulation concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for reducing the ratio of succinic acid fermentation by-products of Actinobacillus succinate, comprising the following steps:

[0026] (1) Preparation of culture medium

[0027] The composition and concentration of the seed medium (g / L): glucose 20, yeast extract 10, corn steep liquor 5, NaCl 2, NaHCO 3 2. NaH 2 PO 4 8.5,K 2 HPO 4 15.5, sterilized at 115°C for 20 minutes;

[0028] Composition and concentration of fermentation medium (g / L): glucose 50, yeast extract 10, corn steep liquor 15, NaHCO 3 4, (NH 4 ) 2 SO 4 2. MgCl 2 .6H 2 O1, CaCl 2 0.3, MnCl 2 0.08, ZnSO 4 0.08, basic MgCO 340, sterilized at 115°C for 20 minutes;

[0029] (2) Seed cultivation

[0030] Inoculate the Actinobacillus succinogenes PZ on the plate into the seed medium, and culture it in an anaerobic box at 37°C or in a common incubator for 16 hours, and the number of bacteria reaches more than 300 million to obtain first-class seeds; then the volume ratio is 5% of ...

Embodiment 2

[0037] Control group: fermentation without addition of bisulfite or metasulfite

[0038] (1)~(2) are with embodiment 1 step (1)~(2);

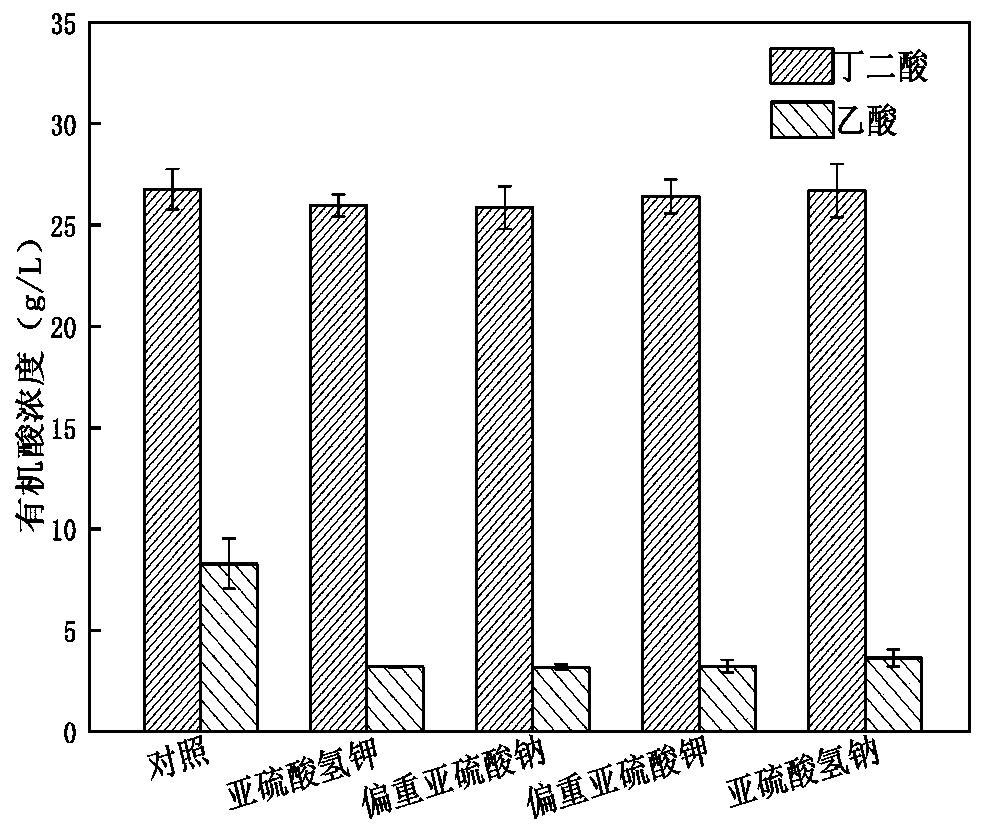

[0039] (3) Insert the secondary seeds into a 250mL anaerobic bottle with 150mL fermentation medium at an inoculum size of 10% by volume. 2 Fermentation in an environment, use basic magnesium carbonate to adjust the fermentation pH to maintain at 6.5-7.0, and carry out fermentation at a speed of 200r / min and a temperature of 37°C for 60h. After the fermentation is over, samples are taken to detect the content of organic acids. The fermentation results are shown in the figure figure 1 shown.

Embodiment 3

[0041] A method for reducing the ratio of succinic acid fermentation by-products of Actinobacillus succinate, comprising the following steps:

[0042] (1) Preparation of culture medium

[0043] The composition and concentration of the seed medium (g / L): glucose 20, yeast extract 10, corn steep liquor 5, NaCl 2, NaHCO 3 2. NaH 2 PO 4 8.5,K 2 HPO 4 15.5, sterilized at 115°C for 20 minutes;

[0044] Composition and concentration of fermentation medium (g / L): glucose 70, yeast extract 10, corn steep liquor 15, NaHCO 3 4, (NH 4 ) 2 SO 4 2. MgCl 2 .6H 2 O1, CaCl 2 0.3, MnCl 2 0.08, ZnSO 4 0.08, basic MgCO 3 Sterilize at 60,115°C for 20 minutes;

[0045] (2) Seed cultivation

[0046] Inoculate the Actinobacillus succinogenes PZ on the plate into the seed medium, and culture it in an anaerobic box at 37°C or in a common incubator for 16 hours, and the number of bacteria reaches more than 300 million to obtain first-class seeds; then the volume ratio is 5% of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com