Microwave-assisted method for efficiently extracting germanium from low-grade germanium-containing material

A microwave-assisted, low-grade technology, applied in the fields of metallurgy and energy, can solve the problem of low germanium recovery rate, achieve the effects of increasing germanium content, low germanium loss rate, and shortening the process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

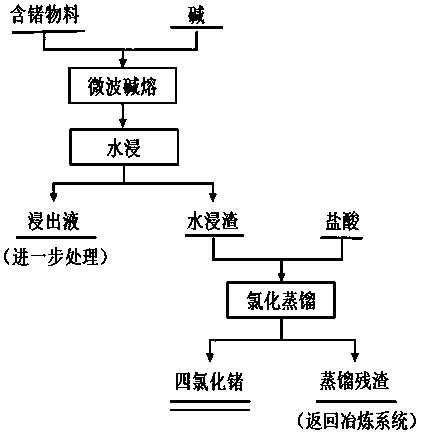

[0021] Embodiment 1: A kind of microwave-assisted method for efficiently extracting germanium in low-grade germanium-containing materials (see figure 1 ),Specific steps are as follows:

[0022] (1) Mix the low-grade germanium-containing material with alkali (potassium hydroxide) to obtain mixture A, heat the mixture A to 200 ° C and keep it warm for 60 minutes, cool to room temperature, and crush to obtain mixture B; the low-grade germanium-containing The composition of the material is shown in Table 1. The mass ratio of low-grade germanium-containing material to alkali (potassium hydroxide) is 1:3; low-grade germanium-containing material and alkali (potassium hydroxide) form germanate, and the reaction formula is

[0023] GeO 2 +2KOH=K 2 GeO 3 +H 2 o

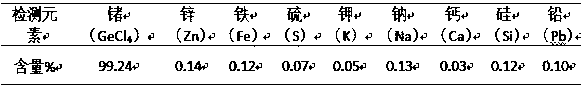

[0024] Table 1 Components of low-grade germanium-containing materials

[0025]

[0026] (2) Add water to the mixture B in step (1) for water immersion reaction for 5 minutes to remove the soluble impurities in the mixt...

Embodiment 2

[0032] Embodiment 2: A kind of microwave-assisted method for efficiently extracting germanium in low-grade germanium-containing materials (see figure 1 ),Specific steps are as follows:

[0033] (1) Mix the low-grade germanium-containing material with alkali (sodium hydroxide) to obtain a mixture A, heat the mixture A to 400 ° C and keep it warm for 30 minutes, cool to room temperature, and crush to obtain a mixture B; the low-grade germanium-containing The composition of the material is shown in Table 3. The mass ratio of low-grade germanium-containing material to alkali (sodium hydroxide) is 1:1; low-grade germanium-containing material and alkali (sodium hydroxide) form germanate, and the reaction formula is

[0034] GeO 2 +2NaOH=Na 2 GeO 3 +H 2 o

[0035] Table 3 Components of low-grade germanium-containing materials

[0036]

[0037] (2) Add water to mixture B in step (1) for water immersion reaction for 15 minutes to remove soluble impurities in mixture B, and sep...

Embodiment 3

[0043] Embodiment 3: A kind of microwave-assisted method for efficiently extracting germanium in low-grade germanium-containing materials (see figure 1 ),Specific steps are as follows:

[0044] (1) Mix low-grade germanium-containing materials with alkali (calcium hydroxide) to obtain mixture A, heat mixture A to 600°C with microwave ovens and keep it warm for 10 minutes, cool to room temperature, and crush to obtain mixture B; among them, low-grade germanium-containing materials The composition of the material is shown in Table 5. The mass ratio of low-grade germanium-containing material to alkali (calcium hydroxide) is 3:1; low-grade germanium-containing material and alkali (calcium hydroxide) form germanate, and the reaction formula is

[0045] GeO 2 +Ca(OH) 2 = Ca 2 GeO 3 +H 2 o

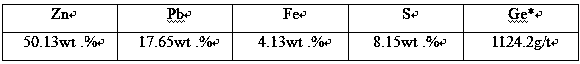

[0046] Table 5 Components of low-grade germanium-containing materials

[0047]

[0048] (2) Add water to the mixture B in step (1) for water immersion reaction for 30 minutes to remove t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com