Air-cooled phase-change cooling motor

A phase-change cooling and air-cooling technology, which is applied in the direction of cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of unguaranteed safety, unfavorable large-scale promotion, and large space occupation, and achieves wide application range and compact structure , the effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

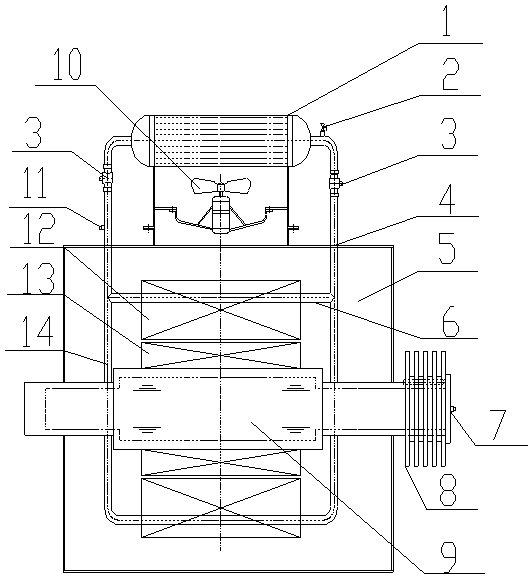

[0036] like figure 1 As shown, it is an air-cooled phase-change cooling motor of the present invention, including a motor casing 5, a motor stator 12, a motor rotor 13, an evaporation tube 6, a stator condenser 7, a rotor condenser, a working medium chamber 9 and a fan 10. The evaporating tube 6 of the present invention runs through the motor stator 12 in the axial direction. A stator condenser 1 is arranged above the motor stator 12. The stator condenser 1 has a working fluid inlet and a working fluid outlet. One end of the evaporating tube 6 passes through the gas phase working fluid The pipeline 14 communicates with the working medium inlet, and the other end communicates with the working medium outlet through the liquid phase working medium pipeline 4 , and the gas phase working medium pipeline 4 is provided with a first working medium fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com