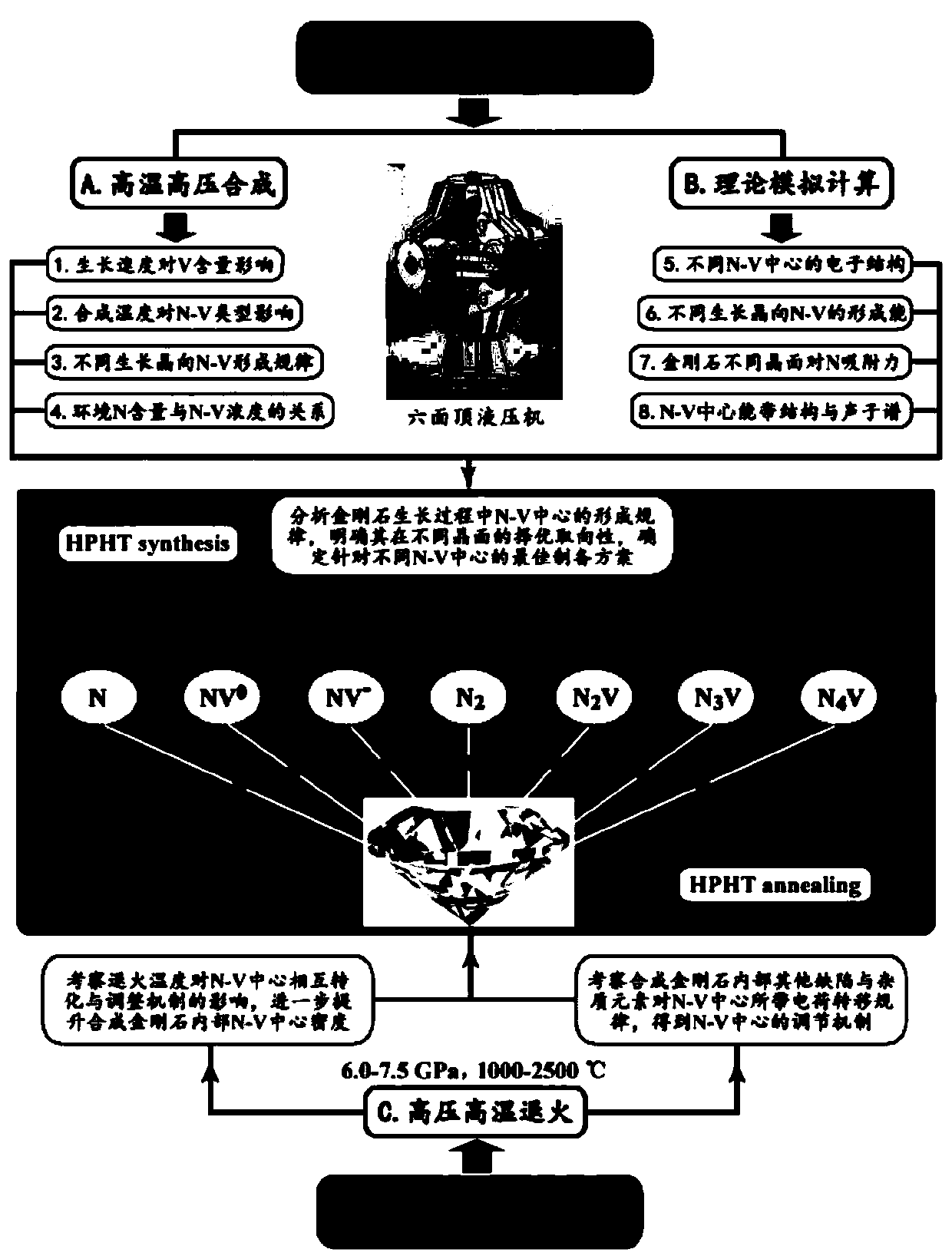

Method for non-destructive controllable preparation of nitrogen vacancy center in diamond

A diamond, non-destructive technology, applied in the field of quantum technology and precision testing materials, to achieve long-term stability of the temperature field, promote the application field, and broaden the application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

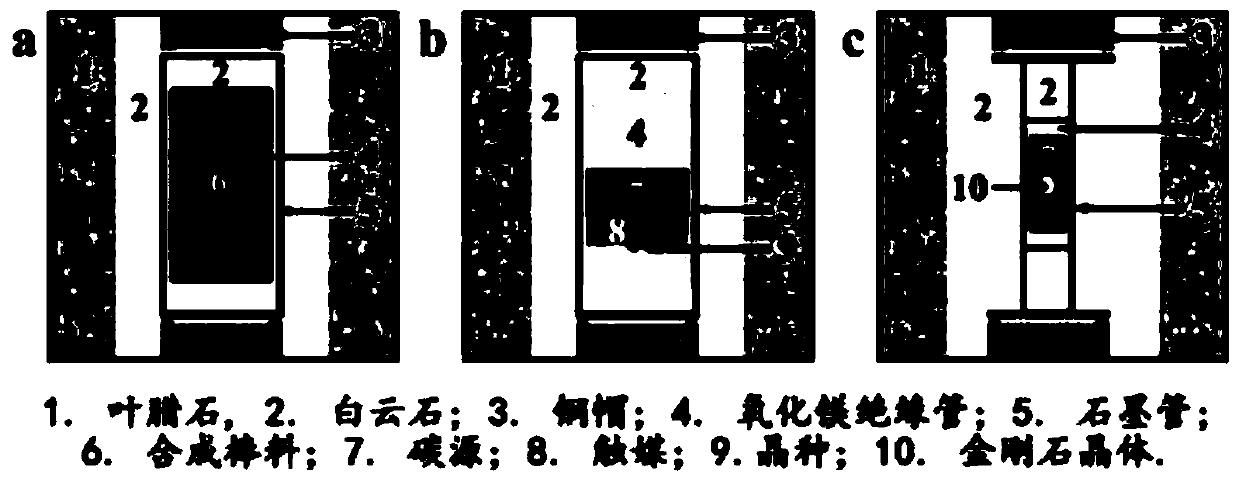

[0043] A method for preparing nitrogen-vacancy centers in diamond without damage and controllable, using the following steps:

[0044] S1: Preparation of diamond single crystals with different content of nitrogen vacancy centers

[0045] (1) Diamond synthesis: Select sulfur to improve the iron-nickel catalyst system, use high-purity flake graphite as the carbon source, and keep it warm for 10 hours at 5.0GPa, 1850°C, and the size of the synthesized high-quality diamond single crystal is 3-5mm;

[0046] (2) Regulate the nitrogen content inside the diamond: Add 0.1wt.% titanium flakes in the catalyst according to the mass ratio to obtain a diamond single crystal with a nitrogen concentration ranging from 0-1 ppm;

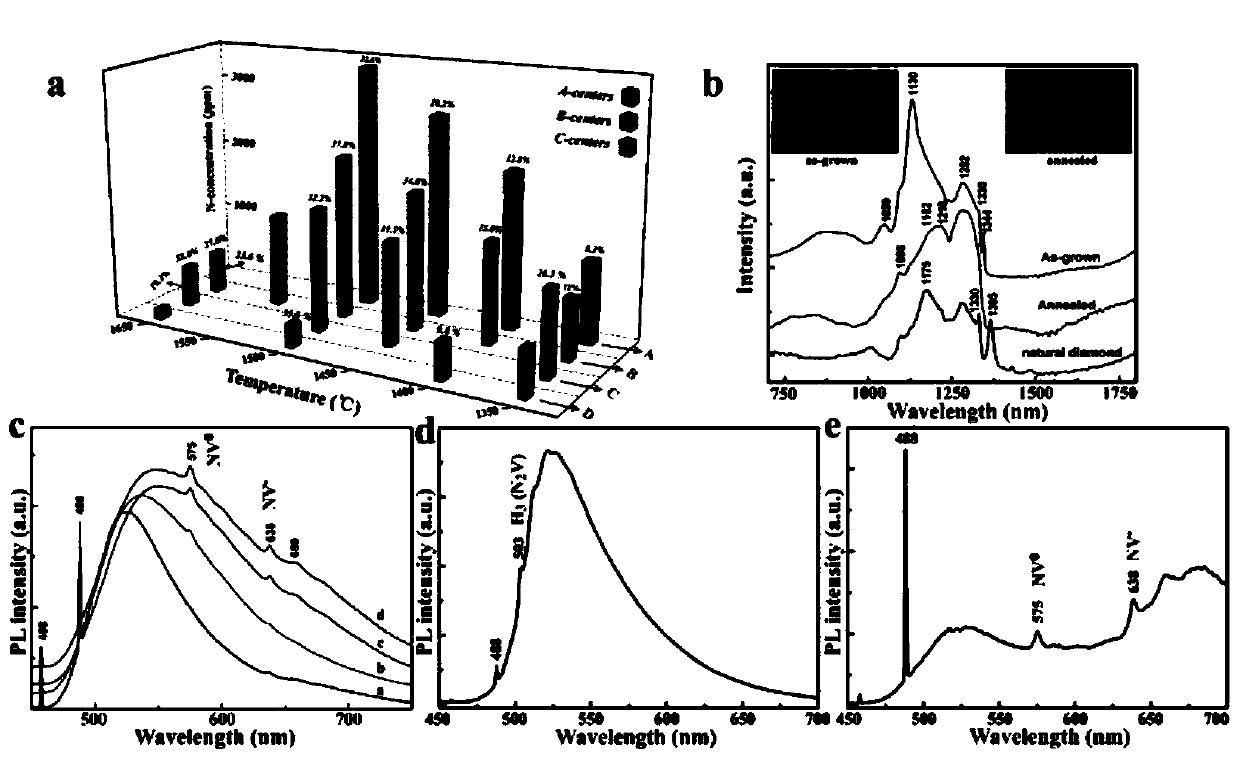

[0047] (3) Controllable nitrogen vacancy type: select {100} seeds respectively, control the diamond growth temperature in the range of 1400-1450°C, and obtain the internal N vacancy 2 V-centered {100} crystals;

[0048] S2: Adjust the type of nitrogen hole center in...

Embodiment 2

[0052] A method for preparing nitrogen-vacancy centers in diamond without damage and controllable, using the following steps:

[0053] S1: Preparation of diamond single crystals with different content of nitrogen vacancy centers

[0054] (1) Diamond synthesis: select phosphorus and other non-metallic elements to improve the iron-nickel catalyst system, use high-purity flake graphite as the carbon source, and keep it at 5.0GPa, 1850°C for 10 hours. The size of the synthesized high-quality diamond single crystal is 3-5mm;

[0055] (2) Regulate the nitrogen content inside the diamond: add 0.1 wt.% C to the carbon source according to the mass ratio 3 N 3 (NH 2 ) 3 , to obtain a diamond single crystal with a nitrogen concentration in the range of 200-1000 ppm;

[0056] (3) Controllable nitrogen vacancy type: select {100} seeds respectively, control the diamond growth temperature in the range of 1400-1450°C, and obtain the internal N vacancy 2 V-centered {100} crystals;

[00...

Embodiment 3

[0061] A method for non-damaging and controllable preparation of nitrogen vacancy centers in diamond, characterized in that the following steps are adopted:

[0062] S1: Preparation of diamond single crystals with different content of nitrogen vacancy centers

[0063] (1) Diamond synthesis: select sulfur non-metallic elements to improve the iron-nickel catalyst system, use high-purity flake graphite as the carbon source, and keep it at 6.0GPa, 1550°C for 40 hours, and the size of the synthesized high-quality diamond single crystal is 3 -5mm;

[0064] (2) Regulate the nitrogen content inside the diamond: Add 1wt.% titanium flakes in the catalyst according to the mass ratio to obtain a diamond single crystal with a nitrogen concentration ranging from 0-1 ppm;

[0065] (3) Controllable nitrogen vacancy type: select {100} seeds, control the diamond growth temperature in the range of 1500-1550°C, and obtain the internal NV 0 with NV - Center-dominated {100} crystals;

[0066] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com