Magnesium oxide based desulfurizing agent and preparation method thereof

A magnesium oxide-based, desulfurizing agent technology, applied in chemical instruments and methods, separation methods, ceramic products, etc., can solve the problems of large pollution emissions, high cost of magnesium oxide desulfurizing agents, and low desulfurization efficiency of calcium-based desulfurizing agents. Achieve excellent performance, realize comprehensive and efficient utilization of resources, and achieve good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

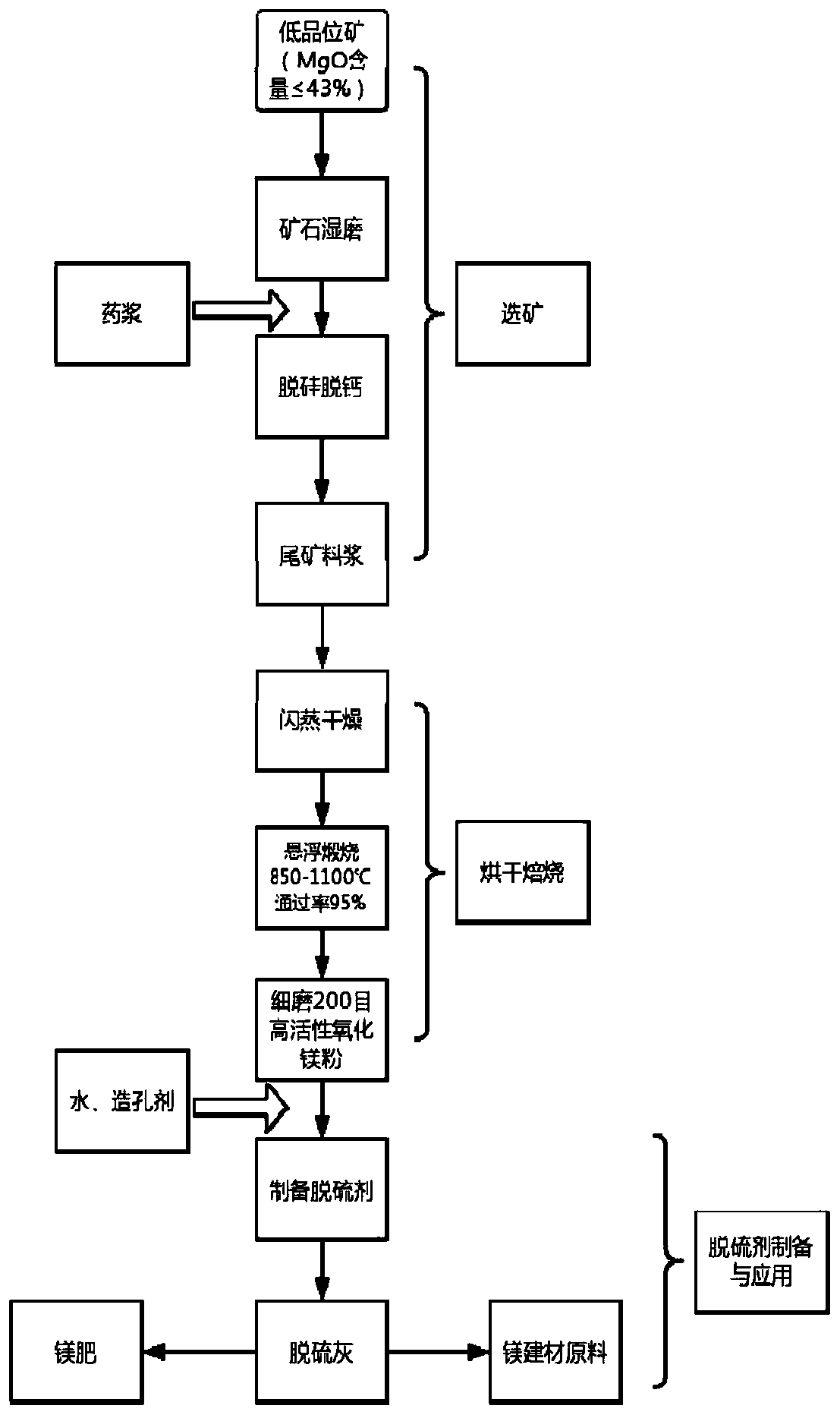

[0031] This embodiment provides a magnesium oxide-based desulfurizer, and the preparation method of the magnesium oxide-based desulfurizer includes the following steps:

[0032] (1) Take magnesite tailings with a magnesium oxide content of ≤43.0%, crush them with a jaw crusher, and feed them into a ball mill for ball milling. Add medicament for desilication and decalcification to obtain a tailing slurry with a fineness of 120 mesh. ;

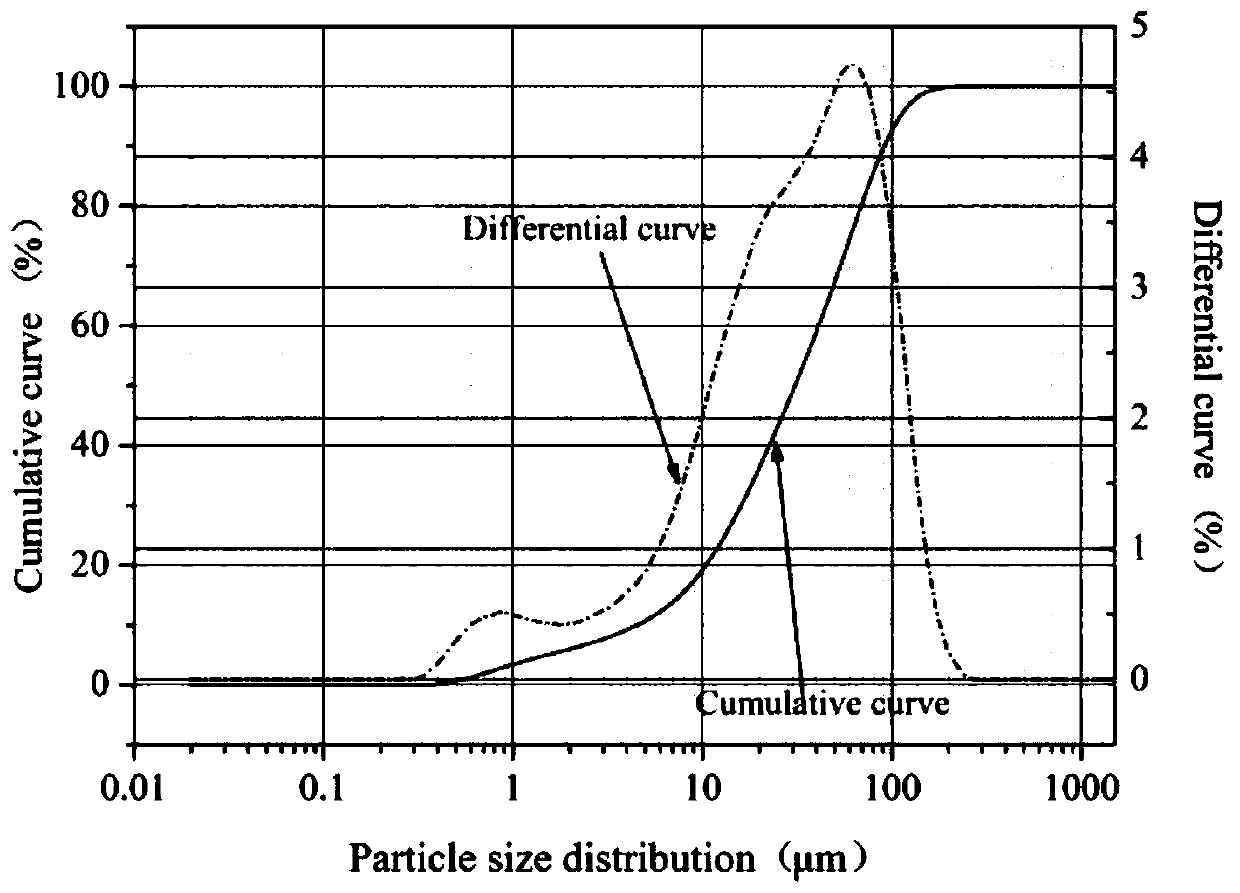

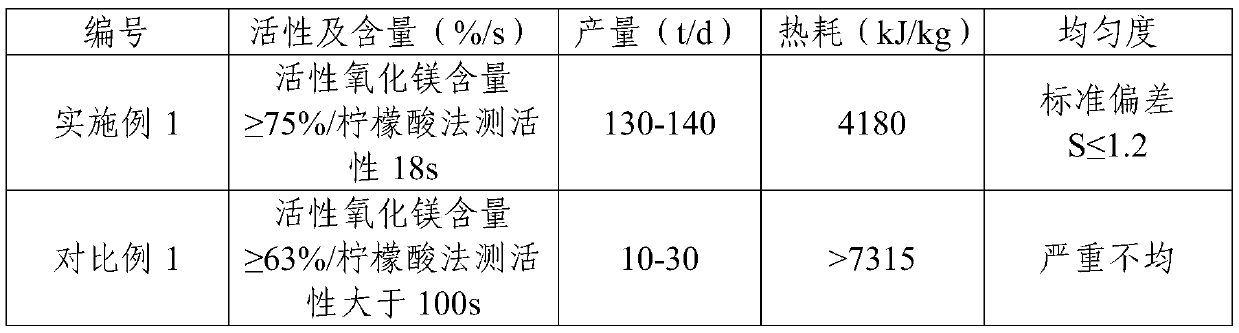

[0033] (2) Feed the tailings slurry through a raw material feeder into a flash dryer for drying, and then feed the dried powder into a suspension kiln. After calcination at 1100°C for 50 minutes, a fineness of 200 meshes, 95% pass rate, and active ≥75% active light-burned magnesia powder (the citric acid method activity determination time is 18 seconds) (where, such as figure 2 As shown, the fineness distribution of the obtained activated light-burned magnesia powder is uniform);

[0034] (3) Add 500 parts by weight of the active light-burned magnes...

Embodiment 2

[0036] This embodiment provides a magnesium oxide-based desulfurizer, and the preparation method of the magnesium oxide-based desulfurizer includes the following steps:

[0037] (1) Take magnesite tailings with a magnesium oxide content of ≤43.0%, crush them with a jaw crusher, and feed them into a ball mill for ball milling. Add medicament for desilication and decalcification to obtain a tailing slurry with a fineness of 120 mesh. ;

[0038] (2) Feed the tailings slurry through a raw material feeder into a flash dryer for drying, and then feed the dried powder into a suspension kiln. After calcination at 850°C for 30 minutes, a fineness of 200 meshes, 95% pass rate, and active ≥75% active light burned magnesium oxide powder;

[0039] (3) Add 500 parts by weight of the active light-burned magnesia powder obtained in step (2), 20 parts by weight of pore-forming agent talc, and 480 parts by weight of water, and mix uniformly to prepare a magnesium oxide-based desulfurizer. The averag...

Embodiment 3

[0041] This embodiment provides a magnesium oxide-based desulfurizer, and the preparation method of the magnesium oxide-based desulfurizer includes the following steps:

[0042] (1) Take magnesite tailings with a magnesium oxide content of ≤43.0%, crush them with a jaw crusher, and feed them into a ball mill for ball milling. Add medicament for desilication and decalcification to obtain a tailing slurry with a fineness of 120 mesh. ;

[0043] (2) Feed the tailings slurry through a raw material feeder into a flash dryer for drying, and then feed the dried powder into a suspension kiln, and pass it through suspension calcination at 1100°C for 50 minutes to obtain a fineness of 200 mesh with a pass rate of 95% and an activity ≥75% active light burned magnesium oxide powder;

[0044] (3) Add 500 parts by weight of the active light-burned magnesia powder obtained in step (2), 50 parts by weight of pore-forming agent talc powder, and 520 parts by weight of water, and mix uniformly to prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com