Preparation method of high-density fine-grain easy-to-form W target material

A fine-grained, high-density technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of difficult, difficult, and expensive process implementation, and reduce the probability of cracking and process. Easy to operate and improve the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

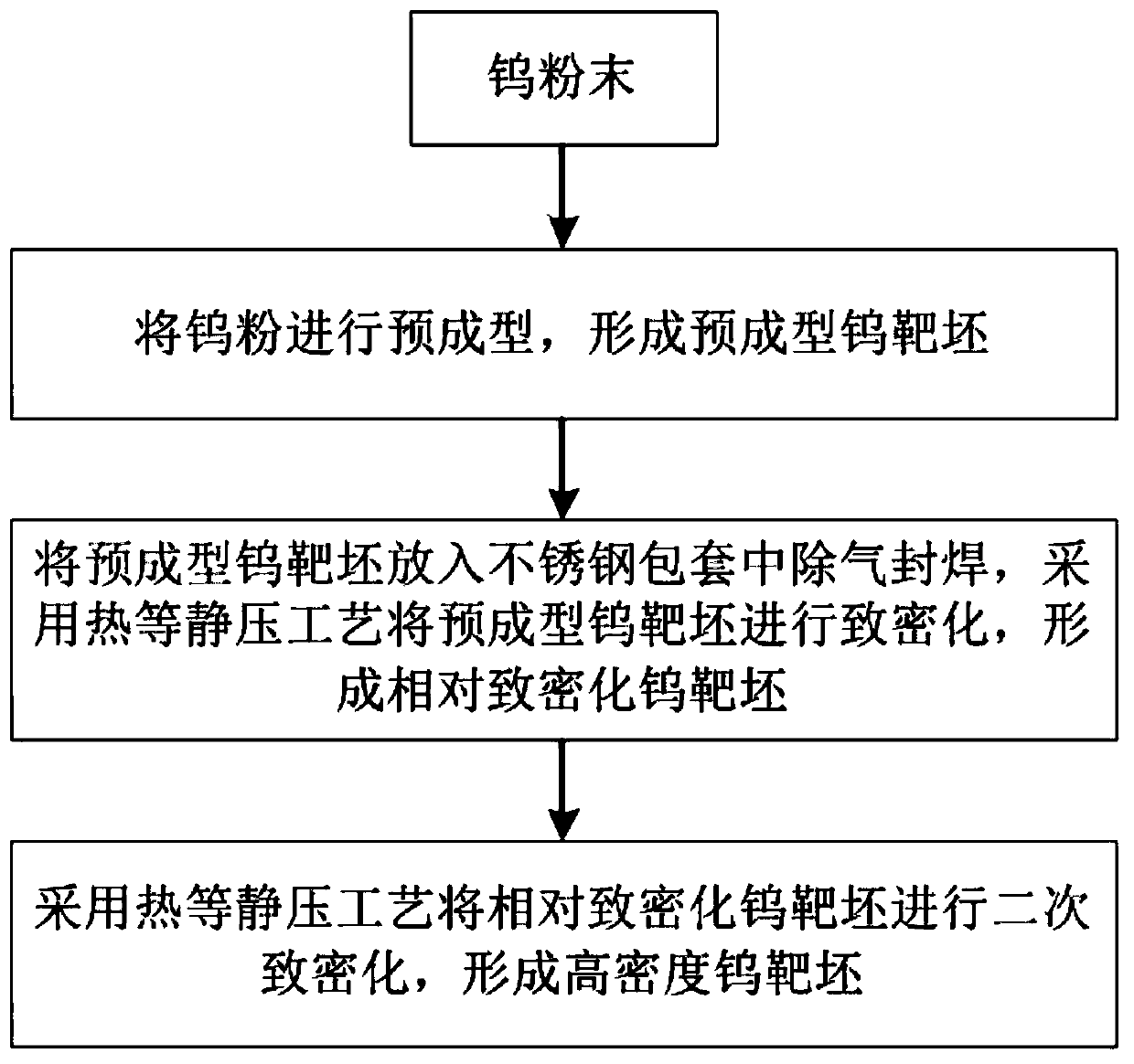

[0030] A method for preparing a high-density fine-grain easy-to-form W target, comprising the following steps:

[0031] S1. Preforming is performed by cold pressing to obtain a preformed W target blank, and the relative density of the preformed W target blank is 60% to 70%;

[0032] S2. Densifying the preformed W target blank by hot isostatic pressing to obtain a densified W target blank. The relative density of the densified W target blank is 93% to 96%;

[0033] S3. Densify the densified W target blank by secondary hot isostatic pressing sintering to obtain a W target; the density of the W target is >99%, the average grain size is 95% %.

[0034] A method for preparing a high-density fine-grain easy-to-form W target, comprising the following steps:

[0035] 1) Weigh the W powder corresponding to the volume of the package, the W powder purity is >5N, and the average particle size is 0.2-0.9 μm;

[0036] 2) Preforming the W powder in step 1) by molding or cold isostatic pre...

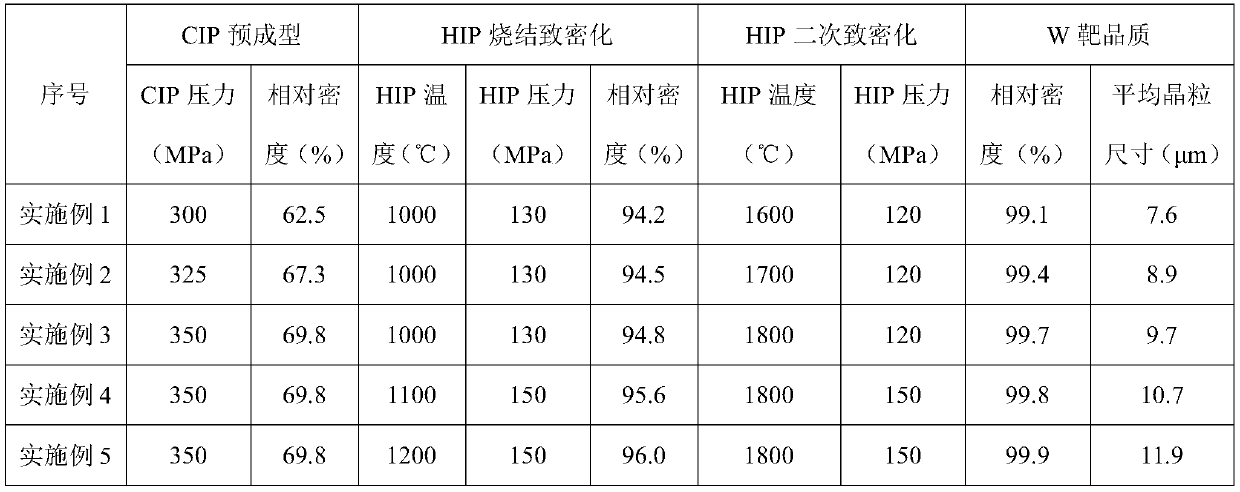

Embodiment 1~5

[0043] 1. Weighing: Weigh the W powder corresponding to the volume of the package, the purity is >5N, and the average particle size is 0.2-0.9 μm.

[0044] 2. Cold isostatic pressing: The weighed W powder is used as raw material, packaged in a rubber sheath, and then preformed by cold isostatic pressing. Density reaches 60% to 70%.

[0045] 3. Degassing and sealing welding: put the preformed W target blank into the stainless steel sheath, and carry out vacuum sealing and welding to make the vacuum degree less than 6×10 -3 Pa.

[0046] 4. Hot isostatic pressing sintering and densification: put the sample after degassing and sealing into the hot isostatic pressing furnace for pressing and sintering. ℃, heat-preservation and pressure-holding for 1-3 hours to obtain a sintered and densified W target blank with a density of 93%-96%.

[0047] 5. Removal of sheath: Take out the sintered and densified W target blank, and remove the stainless steel sheath by machining.

[0048] 6. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com