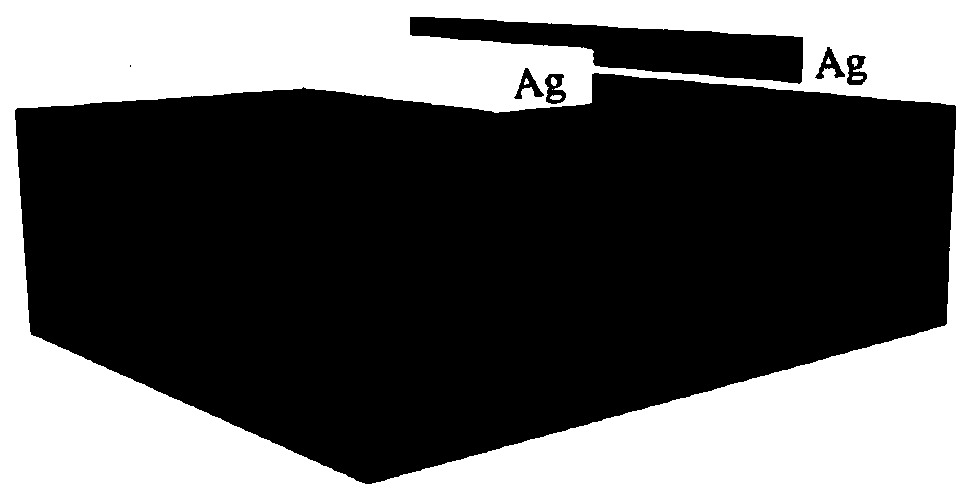

Lead-free double perovskite solar cell and preparation method thereof

A solar cell, double perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low photocurrent, low device efficiency, poor optical absorption capacity, etc., and achieve the effect of improving photocurrent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

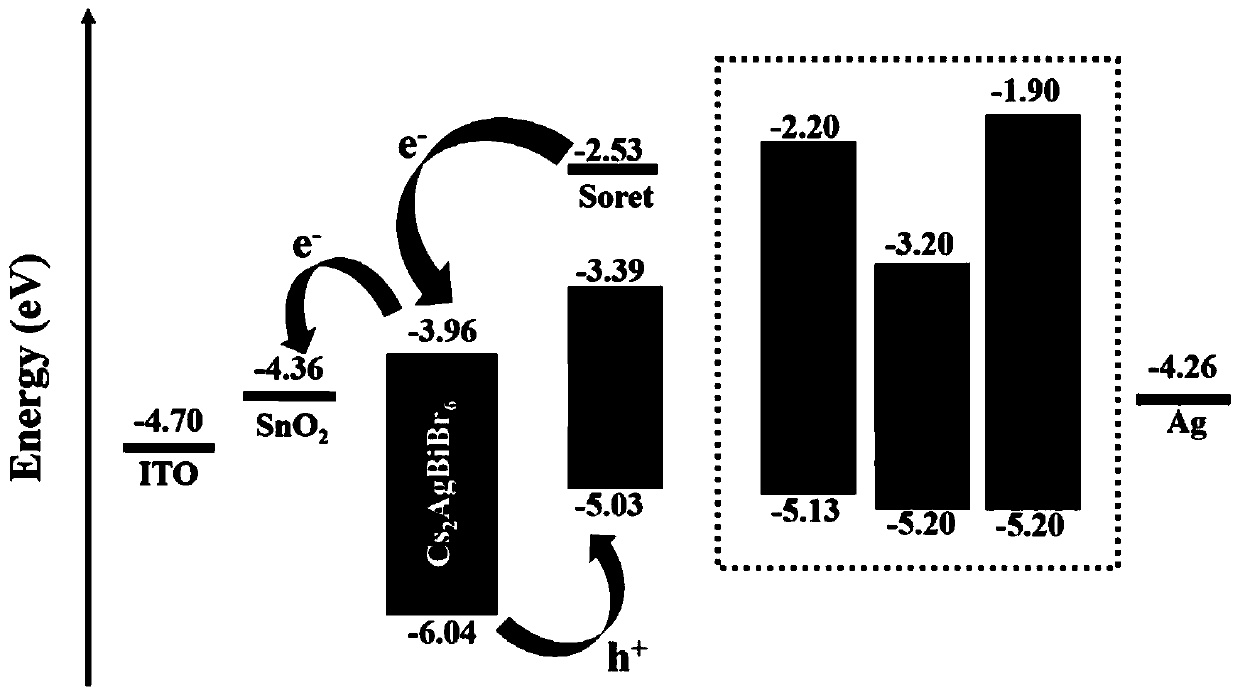

[0051] The present invention provides a kind of preparation method of lead-free double perovskite solar cell, comprising the following steps:

[0052] 1) Treatment of transparent conductive glass cathode:

[0053] Pretreat the cleaned transparent conductive glass with ultraviolet ozone for 30 minutes;

[0054] 2) Preparation and treatment of electron transport layer:

[0055] Put the transparent conductive glass pretreated by UV ozone in step 1) in a homogenizer, spin-coat the colloidal solution of the electron transport layer at a speed of 3000rpm for 30s, and then place it on a hot stage for annealing treatment. The annealing temperature and time are 150 ℃ annealing for 30 minutes; UV ozone treatment for 30 minutes after annealing;

[0056] 3) Preparation of perovskite layer:

[0057] The perovskite precursor Cs 2 AgBr 6 The solution was magnetically stirred on a hot stage at 100°C for 2 hours. After the solution dropped to room temperature, the perovskite precursor Cs ...

Embodiment 1

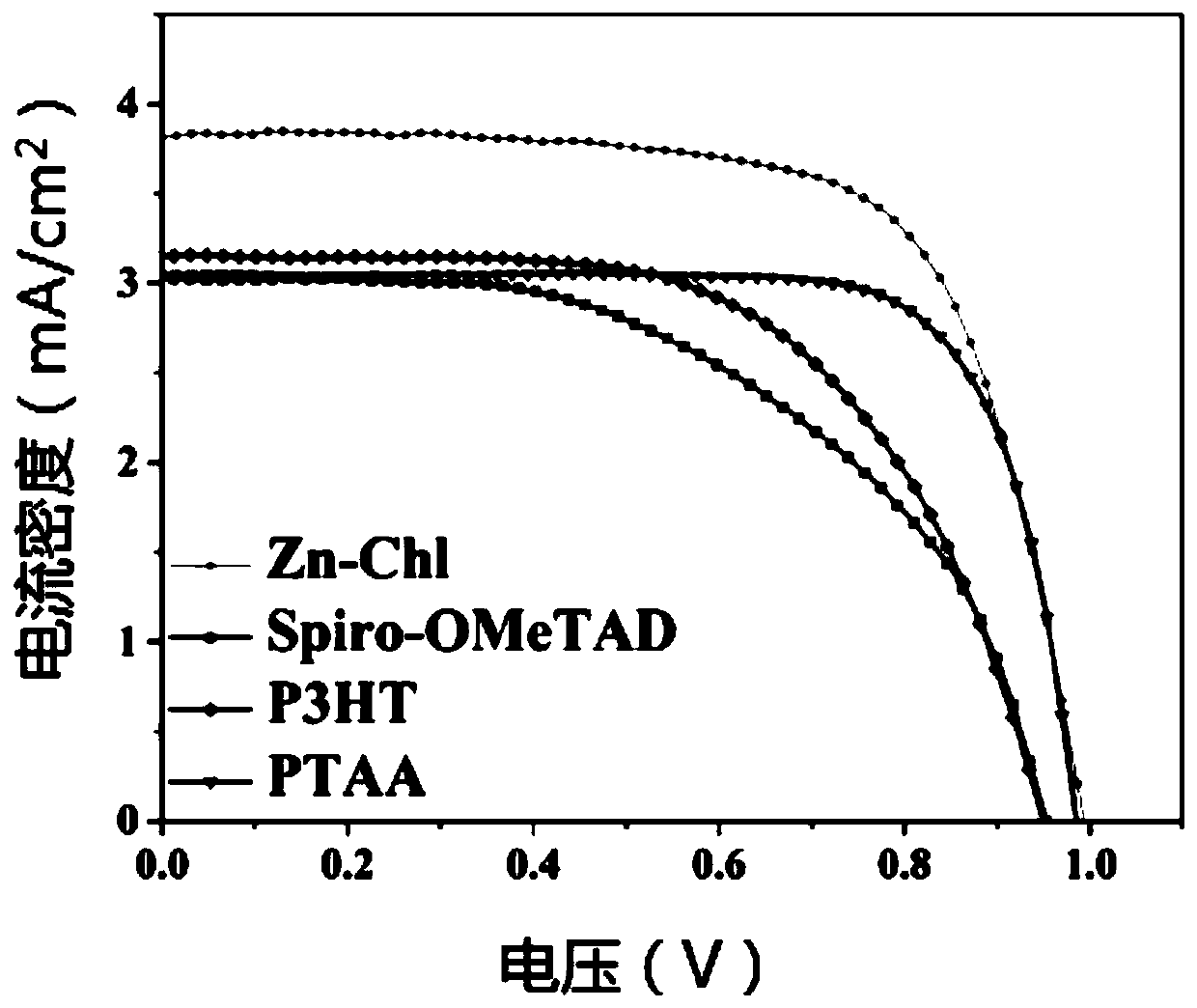

[0069] Sonicate the etched ITO with ITO cleaning agent, deionized water, acetone, alcohol, and isopropanol for 30 minutes, and then prepare SnO 2 colloid, the SnO 2 (15wt.%) hydrocolloid and deionized water are mixed at a volume ratio of 1:4 to obtain SnO 2 (3 wt.%) hydrocolloid. Place the ITO ultraviolet ozone pretreatment on the glue machine after 30 minutes, and the SnO 2 (3.0wt.%) colloid is spin-coated with the rotating speed of 3000rpm 30s, then is placed on the hot stage immediately and carries out annealing treatment, and its annealing temperature and time are 150 ℃ of annealing 30 minutes, then substrate is carried out ultraviolet ozone pretreatment 30 minutes. Preparation of Cs in a nitrogen glove box 2 AgBr 6 Precursor solution, 0.5mM BiBr 3 (224.3 mg) and 0.5 mMol of AgBr (93.9 mg) and 1 mMol of CsBr (212.8 mg) were dissolved in 1 mL of DMSO solution and stirred at 280° C. for 2 hours. Put the substrate into the glove box, spin-coat the perovskite precursor s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com