Liquid pollen food and production method thereof

A technology of liquid pollen and production method, which is applied in the field of dry food and can solve the problems of single ingredient and poor health care function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

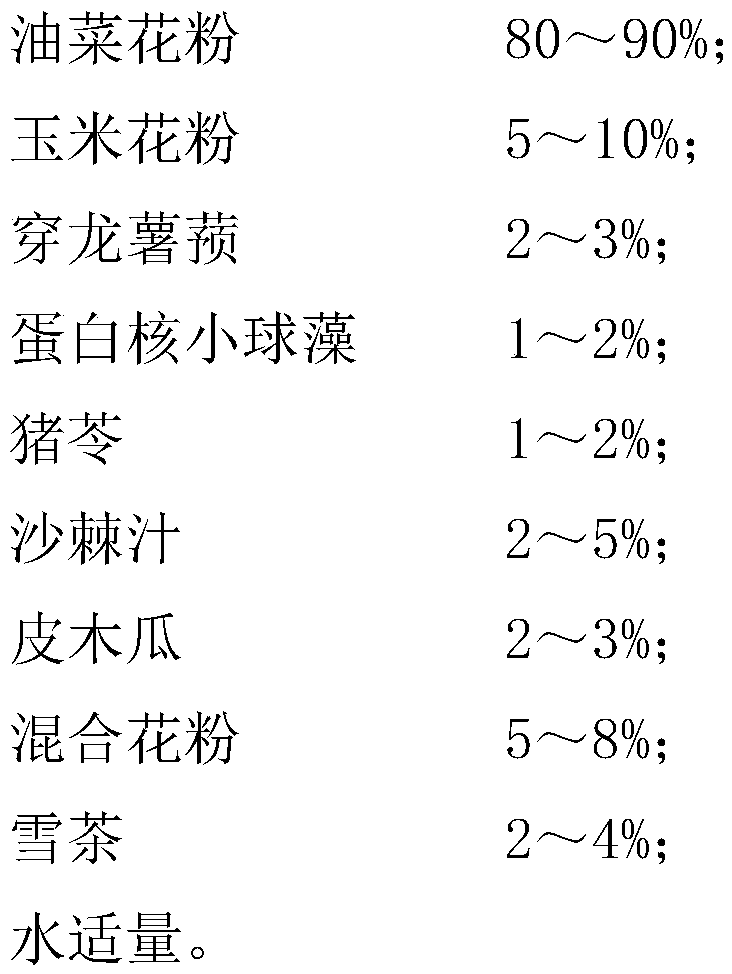

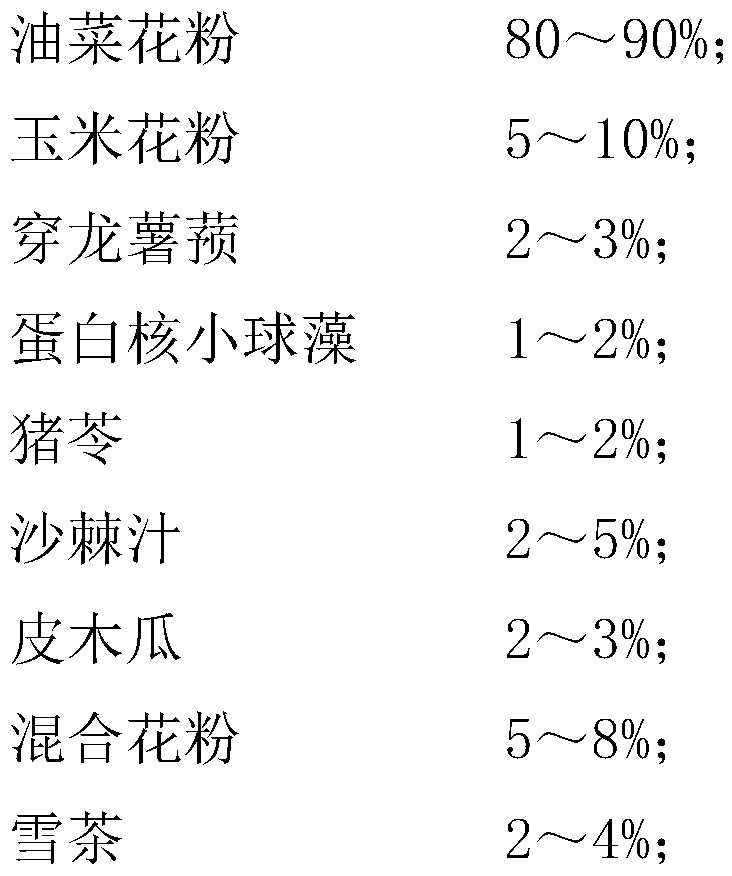

[0062] 1) Mix 80% by weight of rapeseed pollen, 5% by weight of corn pollen and 5% by weight of mixed pollen, put them into a container, take out the treated mixture, add water at 90°C, and place it for 1min. discharge;

[0063] 2) Put the mixture into an aqueous solution containing food-grade hydrogen peroxide, pass oxygen into the aqueous solution, soak for 3 to 8 minutes, then drain the solution, and put it in a heavy metal ion treatment cabinet for treatment;

[0064] 3) Stir and break the treated mixture, add appropriate amount of water, cellulase and α-amylase to the broken mixture, heat to 40°C, soak for 0.5h, then heat to 80°C, and then add Protease, glycosidase and peptidase were stirred for enzymolysis, and reacted for 12 hours to obtain a mixed solution;

[0065] 4) Get 2% by weight of Dioscorea chinensis, 1% by weight of Chlorella pyrenoidosa, 1% by weight of Polyporus, 2% by weight of papaya and 2% by weight of snow tea and mix and soak in 5min in water at 55°C,...

Embodiment 2

[0075] 1) Mix 90% by weight of rapeseed pollen, 10% by weight of corn pollen and 8% by weight of mixed pollen, put them into a container, take out the treated mixture, add water at 95°C, and place it for 2 minutes. discharge;

[0076] 2) Put the mixture into an aqueous solution containing food-grade hydrogen peroxide, pass oxygen into the aqueous solution, soak for 3 to 8 minutes, then drain the solution, and put it in a heavy metal ion treatment cabinet for treatment;

[0077] 3) Stir the treated mixture to break the wall, add appropriate amount of water, cellulase and α-amylase to the broken mixture, heat to 50°C, soak for 0.5h, then heat to 90°C, and then add Protease, glycosidase and peptidase were stirred for enzymolysis, and reacted for 12 hours to obtain a mixed solution;

[0078] 4) Get 3% by weight of Dioscorea chinensis, 2% by weight of chlorella pyrenoidosa, 2% by weight of polyporus, 3% by weight of papaya and 4% by weight of snow tea and mix and soak in 10 minut...

Embodiment 3

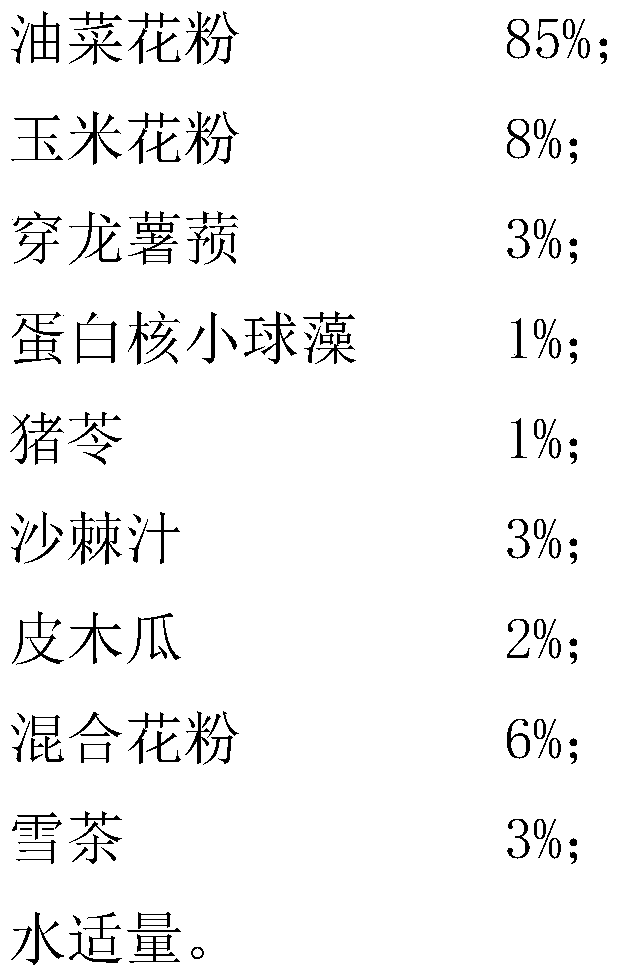

[0088] 1) Mix 85% by weight of rapeseed pollen, 8% by weight of corn pollen and 6% by weight of mixed pollen, put them into a container, take out the treated mixture, add water at 92°C, and place it for 2 minutes. discharge;

[0089] 2) Put the mixture into an aqueous solution containing food-grade hydrogen peroxide, pass oxygen into the aqueous solution, soak for 5 minutes, then drain the solution, and put it into a heavy metal ion treatment cabinet for processing;

[0090] 3) Stir and break the treated mixture, add appropriate amount of water, cellulase and α-amylase to the broken mixture, heat to 45°C, soak for 0.5h, then heat to 88°C, and then add Protease, glycosidase and peptidase were stirred for enzymolysis, and reacted for 12 hours to obtain a mixed solution;

[0091] 4) Get 3% by weight of Dioscorea chinensis, 1% by weight of chlorella pyrenoidosa, 1% by weight of polyporus, 2% by weight of papaya and 3% by weight of snow tea, mix and soak in 8 minutes in water at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com