A kind of multi-layer structure tinicrnb-based self-lubricating pin material and preparation method thereof

A multi-layer structure and pin shaft technology, which is applied in the field of fasteners, can solve problems affecting the use accuracy and normal operation of mechanical parts, affecting the normal disassembly and assembly of mechanical parts, and pitting on the friction contact surface, etc., to achieve the preparation structure Good stability, good tribological properties in wide temperature range, and enhanced bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

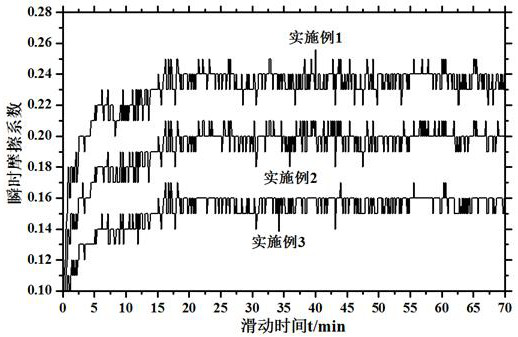

[0033]A multi-layer composite structure TiNiCrNb-based pin shaft material is made of TiNiCrNb-based alloy, friction reducer, anti-wear agent, and reinforcing agent. The structure is divided into friction film, load-bearing transition layer, and matrix load-bearing layer. The total thickness is 10mm. The thickness ratio is 4:17:49.

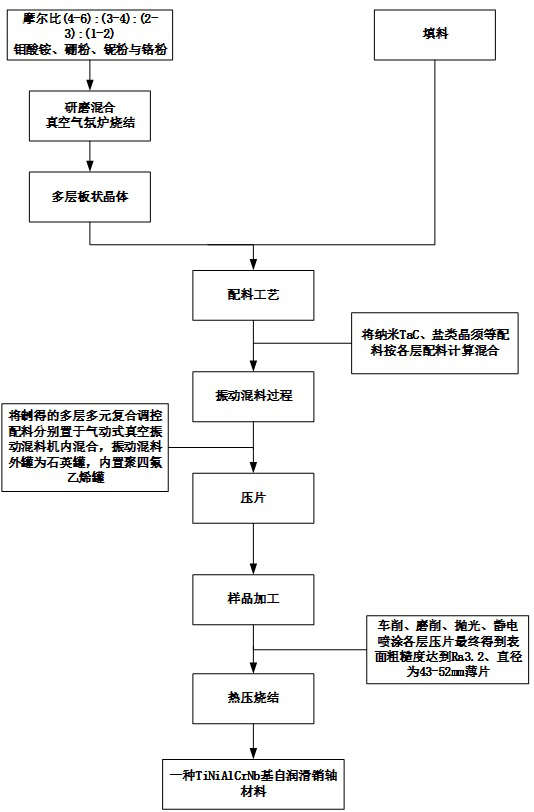

[0034] Such as figure 1 Shown, a kind of multilayer composite structure TiNiCrNb base pin material and preparation method thereof, it comprises the following steps:

[0035] 1) The friction film includes TiNiCrNb-based alloy, friction reducer, antiwear agent and reinforcing agent, and its mass fractions are 8wt.%, 26wt.%, 47wt.% and 19wt.%. The friction reducer is composed of 65wt.% PbSnCuInPt, 15wt.% cerium oxide and 20wt.% multilayer plate crystal MoBNbCrO; the mass ratio of each element of PbSnCuInPt is 18:16:14:12:10. The anti-wear agent is composed of 43wt.% nanometer TaC particles, 39wt.% silicon disulfide and 18wt.% tungsten disulfide. Th...

Embodiment 2

[0045] A multi-layer composite structure TiNiCrNb-based pin shaft material is made of TiNiCrNb-based alloy, friction reducer, anti-wear agent, and reinforcing agent. The structure is divided into friction film, load-bearing transition layer, and matrix load-bearing layer. The total thickness is 10mm. The thickness ratio is 6:23:65.

[0046] Such as figure 1 Shown, a kind of multilayer composite structure TiNiCrNb base pin material and preparation method thereof, it comprises the following steps:

[0047] 1) The contents of TiNiCrNb, friction reducer, antiwear agent and reinforcing agent in the friction film are 13wt.%, 39wt.%, 32wt.% and 16wt.%, respectively. The contents of TiNiCrNb, friction reducer, antiwear agent and reinforcing agent in the bearing transition layer are 40wt.%, 7wt.%, 17wt.% and 36wt.%, respectively. The friction film friction reducer is composed of 60wt.% soft alloy PbSnCuInPt, 30wt.% cerium oxide and 10wt.% multilayer plate crystal MoBNbCrO. The mass ...

Embodiment 3

[0057] A multi-layer composite structure TiNiCrNb-based pin shaft material uses TiNiCrNb-based alloys, friction reducers, anti-wear agents, and reinforcing agents as raw materials. The structure is divided into friction film, bearing transition layer, and matrix bearing layer. The total thickness is 10mm. The ratio is 8:41:72.

[0058] Such as figure 1 Shown, a kind of multilayer composite structure TiNiCrNb base pin material and preparation method thereof, it mainly comprises the following steps:

[0059] The friction film includes TiNiCrNb-based alloy, friction reducer, antiwear agent and reinforcing agent, the mass fractions of which are 13wt.%, 39wt.%, 31wt.% and 17wt.%. The friction reducer is composed of 45wt.% PbSnCuInPt, 31wt.% cerium oxide and 24wt.% multilayer plate crystal MoBNbCrO; the mass ratio of each element of PbSnCuInPt is 29:24:25:23:18. The anti-wear agent is composed of 56wt.% nanometer TaC particles, 21wt.% silicon disulfide and 23wt.% tungsten disulfid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com