Method for comprehensively utilizing seabed sludge

A sludge and sodium hydroxide technology, applied in the field of environmental engineering, can solve problems such as environmental impact, waste of effective resources, full utilization, increase in production costs, etc., and achieve high yield, good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

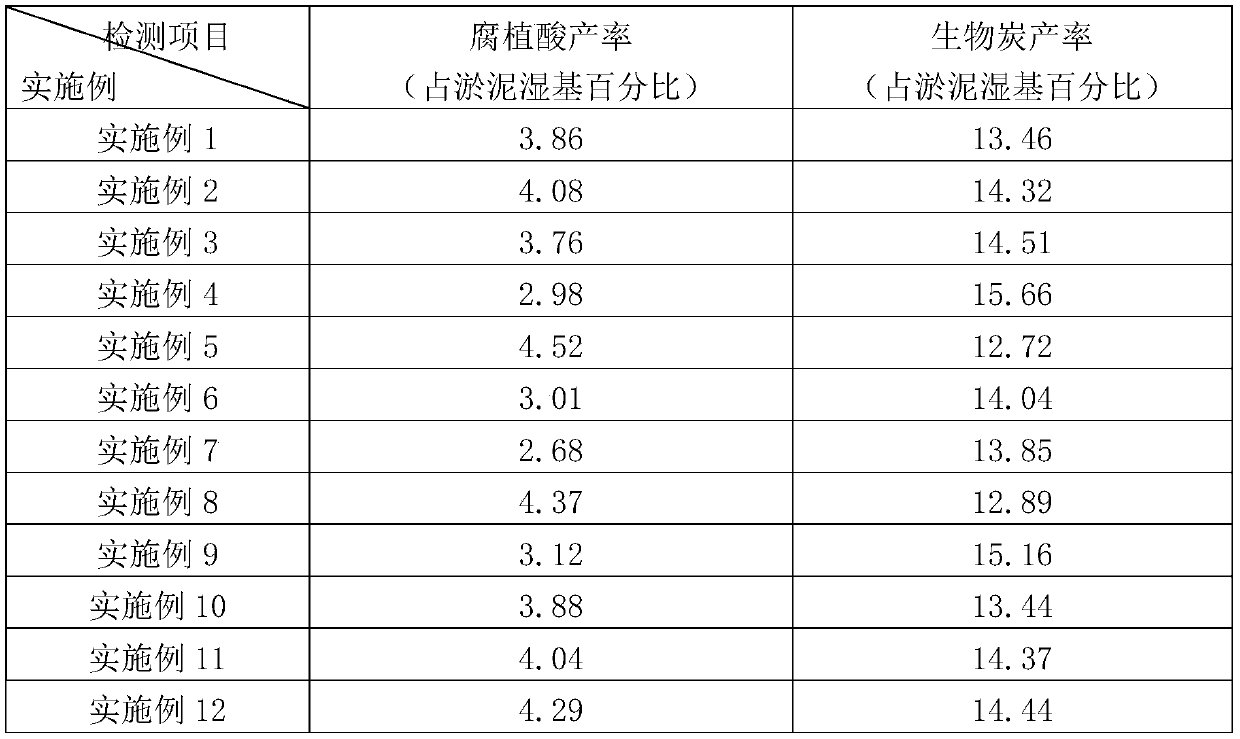

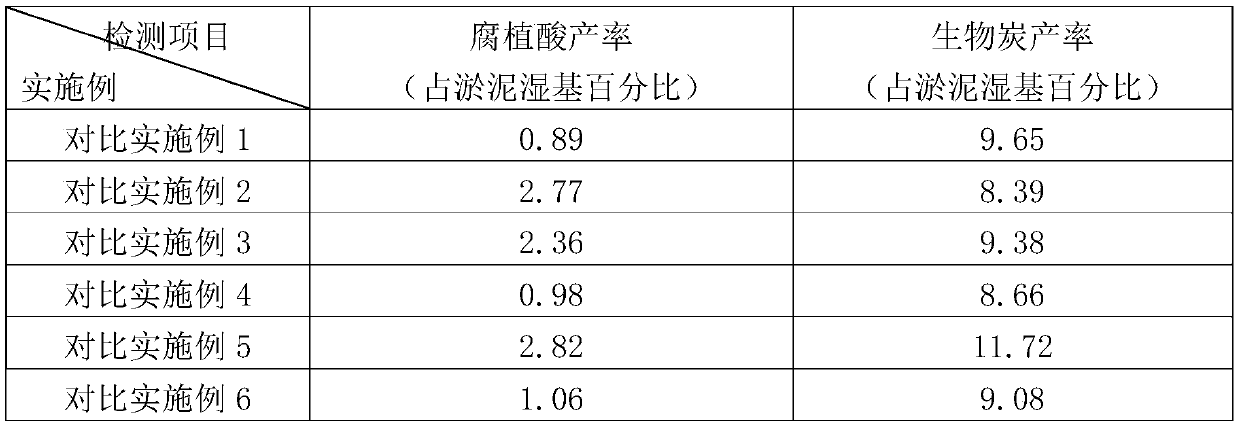

Examples

Embodiment 1

[0034] Suction the mud at the bottom of the tidal flat breeding pond, let it stand to remove the upper liquid, filter the solid part through an 80-mesh sieve, soak and activate it with 11% sodium hydroxide solution, the mass ratio of mud and sodium hydroxide solution is 1:4, stir for 2 hours, and let it stand Set aside for 12 hours, take the upper layer solution and adjust the pH value to 2.0 with hydrochloric acid solution, after standing still, remove the sediment in the lower layer, wash with distilled water for 3 times, and obtain humic acid after drying.

[0035] Add deionized water to the lower sediment after soaking the activated sludge with 11% sodium hydroxide solution, the ratio of the two is the lower sediment: the mass ratio of deionized water is 1:4, and place it in a high-pressure reactor for hydrothermal carbonization reaction. Before the temperature of the reaction kettle is raised, nitrogen gas is passed through the gas phase tube to the reaction chamber for 1...

Embodiment 2

[0038] Collect the seabed silt collected by the dredger, let it stand to remove the supernatant, filter the solid part through an 80-mesh sieve, soak and activate it with 14% sodium hydroxide solution, the mass ratio of sludge to sodium hydroxide solution is 1:5, and stir for 3 hours , stand still for 12 hours, take the upper layer solution and adjust the pH value to 2.2 with hydrochloric acid solution, after standing still, take the lower layer sediment, wash 3 times with distilled water, and obtain humic acid after drying.

[0039] Add deionized water to the lower sediment after soaking the activated sludge with 14% sodium hydroxide solution, the ratio of the two is the lower sediment: the mass ratio of deionized water is 1:3, and place it in an autoclave for hydrothermal carbonization reaction. Before the temperature of the reaction kettle is raised, nitrogen gas is passed through the gas phase tube to the reaction chamber for 15 minutes, and then the gas valve is tightened...

Embodiment 3

[0042] Collect the seabed silt collected by the dredger, let it stand to remove the supernatant, filter the solid part through an 80-mesh sieve, soak and activate it with 17% sodium hydroxide solution, the mass ratio of the sludge to the sodium hydroxide solution is 1:6, and stir for 3 hours , stand still for 12 hours, take the upper layer liquid and adjust the pH value to 2.4 with hydrochloric acid solution, after standing still, take the lower layer sediment, wash 4 times with distilled water, and obtain humic acid after drying.

[0043] Add deionized water to the lower sediment after soaking the activated sludge with 17% sodium hydroxide solution, the ratio of the two is the lower sediment: the mass ratio of deionized water is 1:5, and place it in an autoclave for hydrothermal carbonization reaction. Before the temperature of the reaction kettle is raised, nitrogen gas is passed through the gas phase tube to the reaction chamber for 15 minutes, and then the gas valve is tight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com