Device and method for quickly preparing lambda-Ti3O5 powder

A powder and fast technology, applied in the direction of titanium low-value oxides, titanium oxide/hydroxide, etc., can solve the problems of complex operation process, complex process, long reaction time, etc., and achieve λ-Ti3O5 phase stability, The operation process is simple and the preparation cycle is extremely short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

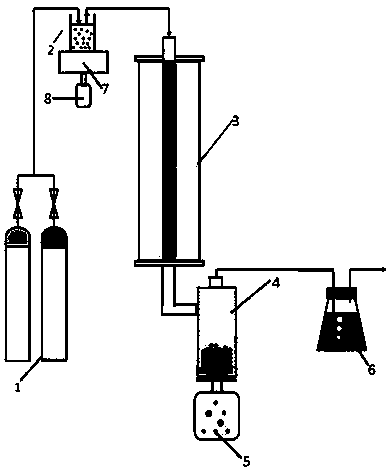

[0031] A Rapid Preparation of λ-Ti 3 o 5 Powder equipment, such as figure 1 As shown, it includes a hydrogen storage tank 1, a material tank 2, a reaction furnace 3, a gas-solid separator 4, a material collection tank 5, an exhaust gas purification device 6, a vibrator 7, and a straight line 8; the hydrogen storage tank 1 is connected to the inlet of the material tank 2 , the bottom of the material tank 2 is provided with a vibrator 7, the bottom of the vibrator 7 is provided with a linear motor 8, the outlet of the material tank 2 is connected to one end of the reaction furnace 3, the other end of the reaction furnace 3 is connected to the gas-solid separator 4, and the gas-solid separator 4 The bottom is connected to the material collection tank 5, the top of the gas-solid separator 4 is connected to the exhaust gas purification device 6, the material tank 2 is provided with a vertical track inside, and there is a groove on the material tank cover, and the groove matches th...

Embodiment 2

[0033] Adopt the device of embodiment 1, prepare λ-Ti rapidly 3 o 5 The powder method, the specific steps are as follows:

[0034] (1) First, replace the air in the reaction device with hydrogen repeatedly, so that the hydrogen atmosphere is maintained in the furnace device; the length of the high-temperature heating section in the reaction furnace 3 is 0.8 meters;

[0035] (2) Dry the commercial P25 powder and put it into the material tank 2, start the vibrator 7 and the linear motor 8, the vibration frequency of the vibrator 7 is 55Hz, the running speed of the output end of the linear motor 8 is 8mm / min, and the vibrator 7 drives The material tank 2 and the titanium dioxide powder inside vibrate, and the linear motor 8 drives the vibrator 7, the material tank 2 and the titanium dioxide powder inside the material tank 2 to move towards the material tank cover, so that the titanium dioxide powder is close to the hydrogen pipe;

[0036] (3) Open the valve of the hydrogen stor...

Embodiment 3

[0044] Adopt the device of embodiment 1, prepare λ-Ti rapidly 3 o 5 The powder method, the specific steps are as follows:

[0045] (1) First, replace the air in the reaction device with hydrogen repeatedly, so that the hydrogen atmosphere is maintained in the furnace device; the length of the high-temperature heating section in the reaction furnace 3 is 1.2 meters;

[0046] (2) Put the commercial P25 powder into the material tank 2 after drying, start the vibrator 7 and the linear motor 8, the vibration frequency of the vibrator 7 is 60Hz, the running speed of the output end of the linear motor 8 is 10mm / min, and the vibrator 7 drives The material tank 2 and the titanium dioxide powder inside vibrate, and the linear motor 8 drives the vibrator 7, the material tank 2 and the titanium dioxide powder inside the material tank 2 to move towards the material tank cover, so that the titanium dioxide powder is close to the hydrogen pipe;

[0047] (3) Open the valve of the hydrogen s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com