Green continuous process and device for purifying amino-dodecanoic acid product

A technology of aminododecanoic acid and products, which is applied in the field of green continuous process and equipment, to achieve the effects of high purity, color removal and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

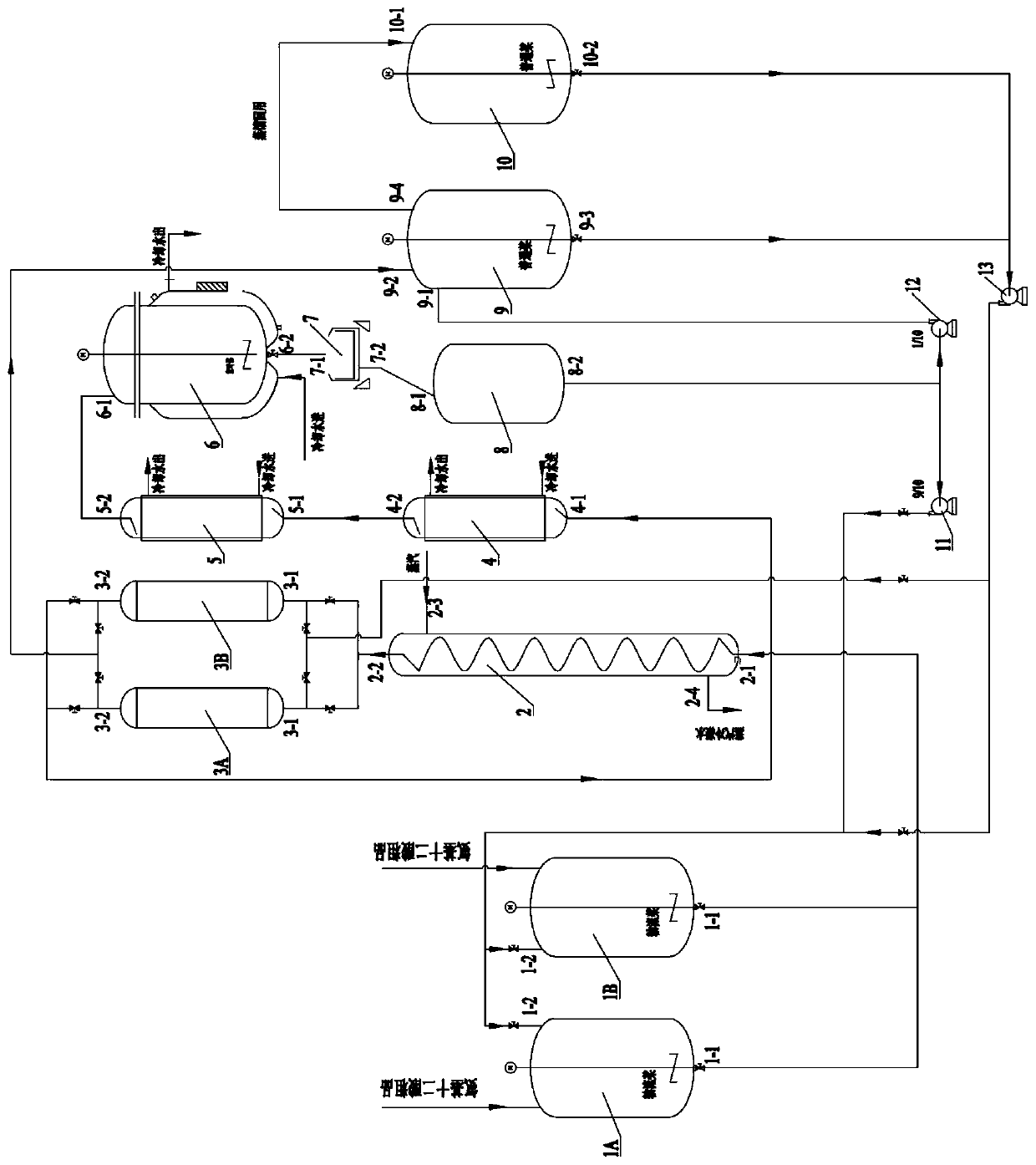

Method used

Image

Examples

Embodiment 1

[0067] A green continuous process for purifying aminododecanoic acid product, comprising the following steps:

[0068] (1) Put 100kg of aminododecanoic acid crude product and water into the slurry mixer at a ratio of 1:9, and stir well;

[0069] (2) Turn on nitrogen and pressurize to 0.21MPa, press the mixed material liquid into the heating melting processor at a speed of 9kg / h for heating and dissolving, make it reach the required temperature of 120°C, and then send the dissolved material liquid to the adsorption bed;

[0070] (3) Regulating the discharge temperature of the heating-up melting processor, so that the temperature of the feed liquid in the adsorption bed is 119° C., and the filtration of the fatty acid derivative and the desorption of char and pigment are carried out;

[0071] (4) Cool down by 4°C from the adsorption bed through the first pre-crystallizer, and the feed liquid slowly forms crystal nuclei during the cooling process;

[0072] The temperature of th...

Embodiment 2

[0076] With the same process conditions as in Example 1, the aminododecanoic acid crude product was purified by batching in another slurry mixer (the difference: the centrifuged liquid in the liquid collection tank was used for batching at 1:9), centrifugal sampling analysis (2#) Relevant index detection is shown in Table 2;

Embodiment 3

[0078] Continue to repeat the operation of embodiment 2, denoted as 3#, centrifuge sampling analysis test result relevant index detection is shown in Table 2:

[0079] After the above slurry ingredients are alternately used and cycled 11 times, adjust the pH value of the regeneration treatment solution to 9, regenerate the adsorption bed, circulate at a speed of 30kg / h, and regenerate at a temperature of 90°C for 140 minutes. Rinse with a little clean water. End when the pH value is 7;

[0080] Regeneration is completed, operate according to the process conditions of the above-mentioned embodiment 1, and the ingredients are purified to the crude product, and the relevant index detection of centrifugal sampling analysis (4#, 5#) is shown in Table 2:

[0081] Under different conditions, after refining and purifying the aminododecanoic acid crude product, the analysis results of 5 times were compared, and the results are shown in Table 2:

[0082] Table 2 Aminododecanoic acid qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

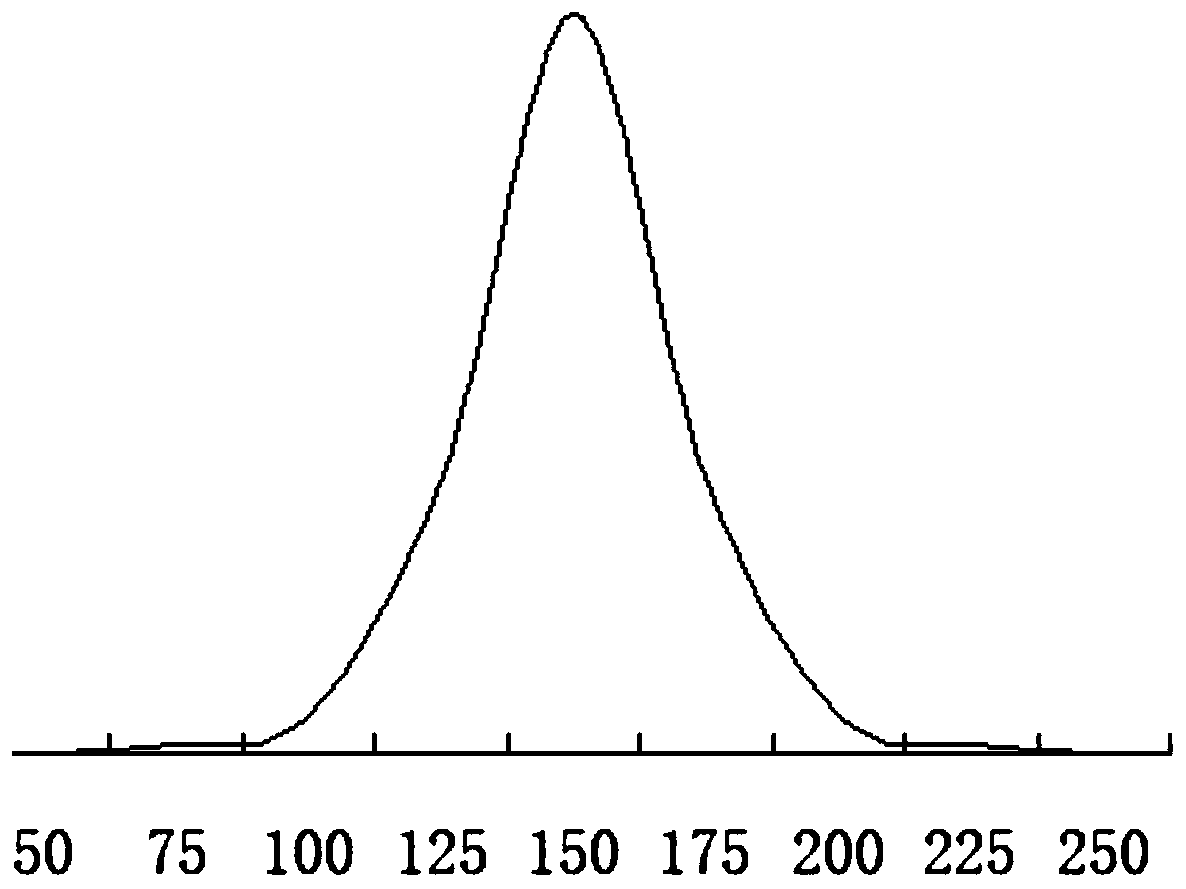

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com