Preparation method of nano carbon black reinforced HDPE water supply pipe

A technology of nano-carbon black and water supply pipes, which is applied in the direction of general water supply saving, tubular objects, applications, etc., can solve the problems of strong coloring ability, large specific surface area of nano-carbon black, and defects in oxidation resistance, and achieve strong coloring ability and anti-oxidation Increased oxidation degree and hydrostatic strength, wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

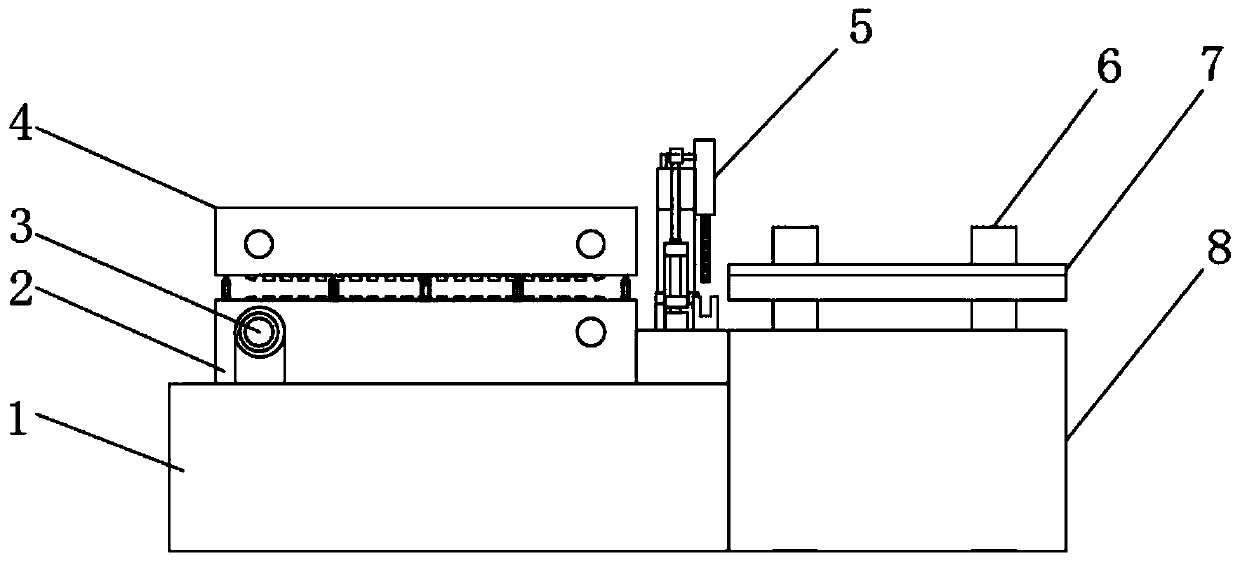

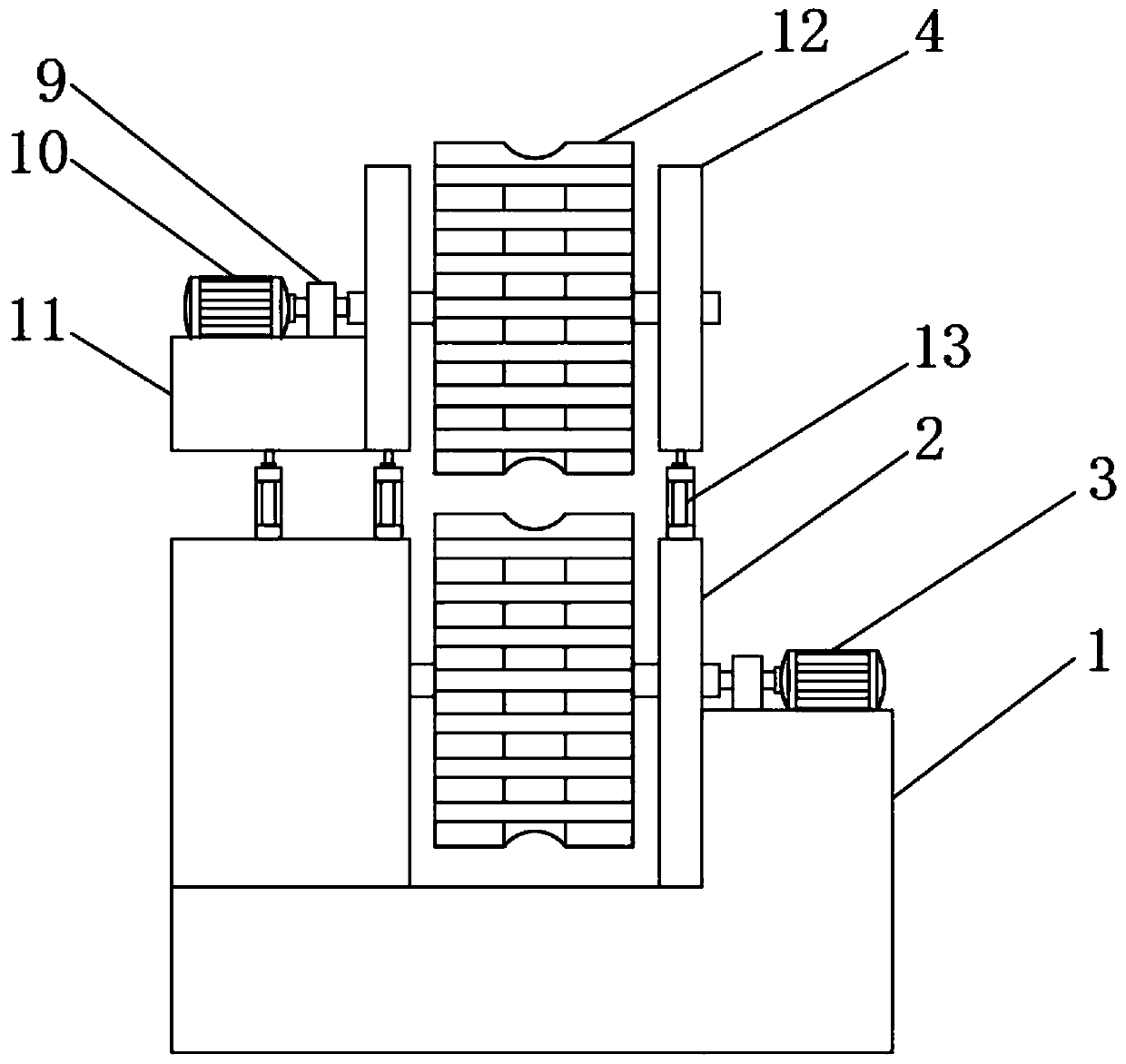

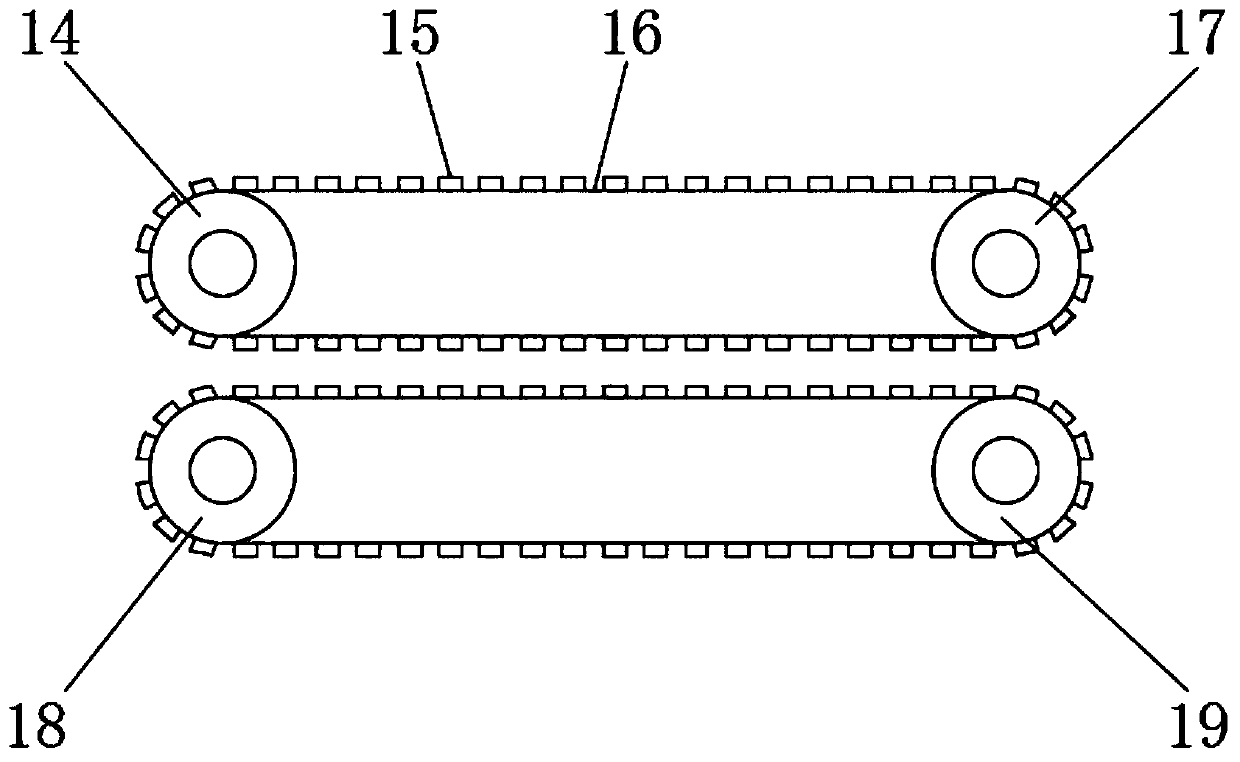

[0044] see Figure 1-10 As shown, this embodiment is a method for preparing a nano-carbon black reinforced HDPE water supply pipe, which includes the following components in parts by weight: 90 parts of HDPE resin, 10 parts of high-gloss black masterbatch;

[0045] The composition of the high-gloss black masterbatch includes the following components in parts by weight: 40 parts of HDPE resin, 30 parts of treated nano-carbon black, 2 parts of lubricant, 4 parts of processing aid, 1 part of antioxidant, and 2 parts of light stabilizer;

[0046] The treated nano carbon black comprises the following components by weight: 80 parts of nano carbon black, 8 parts of polyolefin hyperdispersant, 3 parts of graft copolymer hyperdispersant, and 1 part of surface synergist;

[0047] The nano-carbon black reinforced HDPE water supply pipe is prepared by the following steps:

[0048] Step 1: Weigh the raw materials by weight, send nano-carbon black evenly to the high-speed mixer by high-spe...

Embodiment 2

[0058] see Figure 1-10 As shown, this embodiment is a preparation method of nano-carbon black reinforced HDPE water supply pipes, the nano-carbon black reinforced HDPE water supply pipes include the following components by weight: 100 parts of HDPE resin, 15 parts of high-gloss black masterbatch;

[0059] The composition of the high-gloss black masterbatch includes the following components in parts by weight: 50 parts of HDPE resin, 40 parts of treated nano-carbon black, 4 parts of lubricant, 6 parts of processing aid, 2 parts of antioxidant, and 3 parts of light stabilizer;

[0060] The treated nano-carbon black comprises the following components by weight: 90 parts of nano-carbon black, 12 parts of polyolefin hyperdispersant, 6 parts of graft copolymer hyperdispersant, and 3 parts of surface synergist;

[0061] The nano-carbon black reinforced HDPE water supply pipe is prepared by the following steps:

[0062] Step 1: Weigh the raw materials by weight, send nano-carbon bla...

Embodiment 3

[0072] see Figure 1-10 As shown, this embodiment is a preparation method of nano-carbon black reinforced HDPE water supply pipes, the nano-carbon black reinforced HDPE water supply pipes include the following components by weight: 110 parts of HDPE resin, 20 parts of high-gloss black masterbatch;

[0073] The composition of the high-gloss black masterbatch includes the following components in parts by weight: 60 parts of HDPE resin, 50 parts of treated nano-carbon black, 6 parts of lubricant, 8 parts of processing aid, 3 parts of antioxidant, and 4 parts of light stabilizer;

[0074] The treated nano carbon black comprises the following components by weight: 100 parts of nano carbon black, 16 parts of polyolefin hyperdispersant, 9 parts of graft copolymer hyperdispersant, and 5 parts of surface synergist;

[0075] The nano-carbon black reinforced HDPE water supply pipe is prepared by the following steps:

[0076] Step 1: Weigh the raw materials by weight, send nano-carbon bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com