Production method of pumpkin polysaccharide yoghourt

A production method, pumpkin polysaccharide technology, applied in milk preparations, dairy products, bacteria used in food preparation, etc., to achieve the effects of inhibiting post-acidification process, improving quality, and delaying the rise of acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

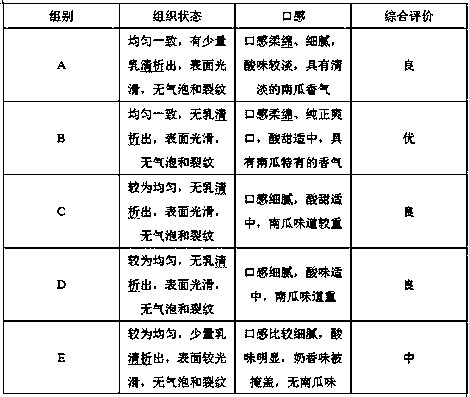

Image

Examples

Embodiment 1

[0025] The pumpkin polysaccharide yoghurt rich in dietary fiber produced in this implementation example is made by adding components and mixing fermentation according to the following weight percentages of fresh milk: 100 parts of fresh milk, 7% of high-quality white sugar, 0.50% of pumpkin crude polysaccharide, chrysanthemum 2% powder, 3% starter, 0.25% stabilizer (0.1% sodium carboxymethylcellulose, 0.05% xanthan gum, 0.1% pectin), 0.2% resistant dextrin %, monoglyceride 0.2%, whey protein powder 0.2%.

[0026] Making the above-mentioned pumpkin polysaccharide yogurt rich in dietary fiber includes the following steps:

[0027] (1) Extraction of pumpkin polysaccharides: Fresh pumpkins were peeled, fleshed, washed, sliced, baked in an oven at 70°C for 24 hours, crushed, and passed through a 100-mesh sieve to obtain pumpkin powder. Accurately weigh 50g of pumpkin powder, add 1500mL of distilled water, then add 1.0% of cellulase, 1.5% of pectinase, 1.0% of papain compound enzym...

Embodiment 2

[0034] The pumpkin polysaccharide yoghurt rich in dietary fiber of this embodiment is obtained by adding the components mixed and fermented according to the following weight percentages of fresh milk: 100 parts of fresh milk, 8% of high-quality white sugar, 0.6% of pumpkin crude polysaccharide, and 0.6% of inulin 3%, 4% starter culture, 0.43% stabilizer (0.20% sodium carboxymethyl cellulose, 0.03% xanthan gum, 0.2% pectin), 0.2% resistant dextrin, single Glyceride 0.2%, whey protein powder 0.2%.

[0035] Making the above-mentioned pumpkin polysaccharide yogurt rich in dietary fiber includes the following steps:

[0036] (1) Extraction of pumpkin polysaccharides: Fresh pumpkins were peeled, fleshed, washed, sliced, baked in an oven at 70°C for 24 hours, crushed, and passed through a 100-mesh sieve to obtain pumpkin powder. Accurately weigh 50g of pumpkin powder, add 1500mL of distilled water, then add 1.0% of cellulase, 1.5% of pectinase, 1.0% of papain compound enzyme, and pl...

Embodiment 3

[0043] The pumpkin polysaccharide yogurt rich in dietary fiber in this implementation example is obtained by adding components and mixing fermentation according to the following weight percentages of fresh milk: 100 parts of fresh milk, 8% of high-quality white sugar, 0.9% of pumpkin polysaccharide, and 4% of inulin , the amount of starter is 4.5%, the stabilizer is 0.45% (of which sodium carboxymethylcellulose is 0.20%, xanthan gum is 0.05%, pectin is 0.2%), resistant dextrin is 0.2%, monoglyceride 0.2%, whey protein powder 0.2%.

[0044] Making the above-mentioned pumpkin polysaccharide yogurt rich in dietary fiber includes the following steps:

[0045] (1) Extraction of pumpkin polysaccharides: Fresh pumpkins were peeled, fleshed, washed, sliced, baked in an oven at 70°C for 24 hours, crushed, and passed through a 100-mesh sieve to obtain pumpkin powder. Accurately weigh 50g of pumpkin powder, add 1500mL of distilled water, then add 1.0% of cellulase, 1.5% of pectinase, 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com