Magnesium-added limestone wet flue gas desulfurization method

A wet flue gas desulfurization and limestone technology, which is applied in the field of flue gas purification, can solve the problems of high price of magnesium oxide desulfurization raw materials, high power consumption, poor desulfurization performance of limestone, etc., and achieve excellent desulfurization performance, high desulfurization efficiency, The effect of increasing flexibility and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

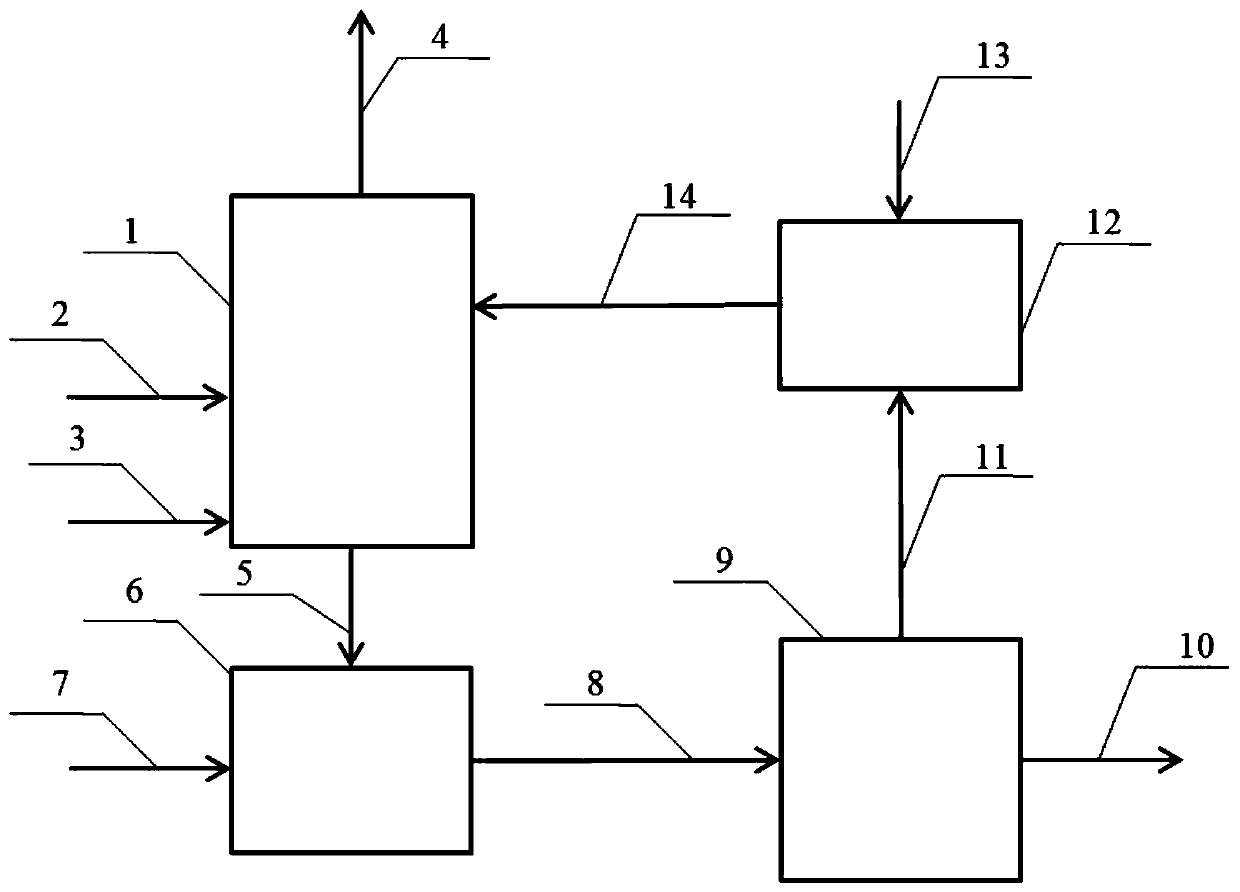

[0071] A magnesium limestone wet flue gas desulfurization method, the magnesium limestone wet flue gas desulfurization method is desulfurization absorption, oxidation, separation and dehydration, slurry recovery four steps cycle desulfurization method, the specific steps are as follows:

[0072] S1, desulfurization absorption

[0073] The raw flue gas containing sulfur dioxide passes through the desulfurization absorption system from bottom to top, and the sulfur dioxide absorbent is sprayed from the top of the desulfurization absorption system to perform absorption reaction with the flue gas containing sulfur dioxide. The sulfur dioxide absorbent is magnesium limestone, and the absorption reaction is , keep the magnesium ion concentration at 2,000-20,000ppm, the pH value of the slurry is 4.5-7.0, the solid matter content in the desulfurization slurry is 10-22%, Cl - The concentration is 10,000~20,000ppm;

[0074] S2, oxidation

[0075] Discharging the desulfurized slurry in...

Embodiment 2

[0081] A magnesium limestone wet flue gas desulfurization method, the magnesium limestone wet flue gas desulfurization method is desulfurization absorption, oxidation, separation and dehydration, slurry recovery four steps cycle desulfurization method, the specific steps are as follows:

[0082] S1, desulfurization absorption

[0083] The flue gas containing sulfur dioxide passes through the desulfurization absorption system from bottom to top, and the sulfur dioxide absorbent is sprayed from the top of the desulfurization absorption system to perform absorption reaction with the flue gas containing sulfur dioxide. The sulfur dioxide absorbent is magnesium limestone. During the absorption reaction, Keep the concentration of magnesium ions at 4,000-10,000ppm, the pH value of the slurry is 5.5-6.5, the solid matter content in the desulfurization slurry is 15-18%, Cl - The concentration is 15,000~18,000ppm;

[0084] S2, oxidation

[0085] Discharging the desulfurized slurry in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com