A kind of synthesis method of tetrazine hypercrosslinked porous photocatalyst

A technology of photocatalyst and synthesis method, applied in chemical instruments and methods, physical/chemical process catalysts, catalytic reactions, etc., can solve the problems of homogeneous catalysts that are difficult, difficult to recycle, expensive, etc., and achieve large specific surface area and density Effect of small and wide visible light absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

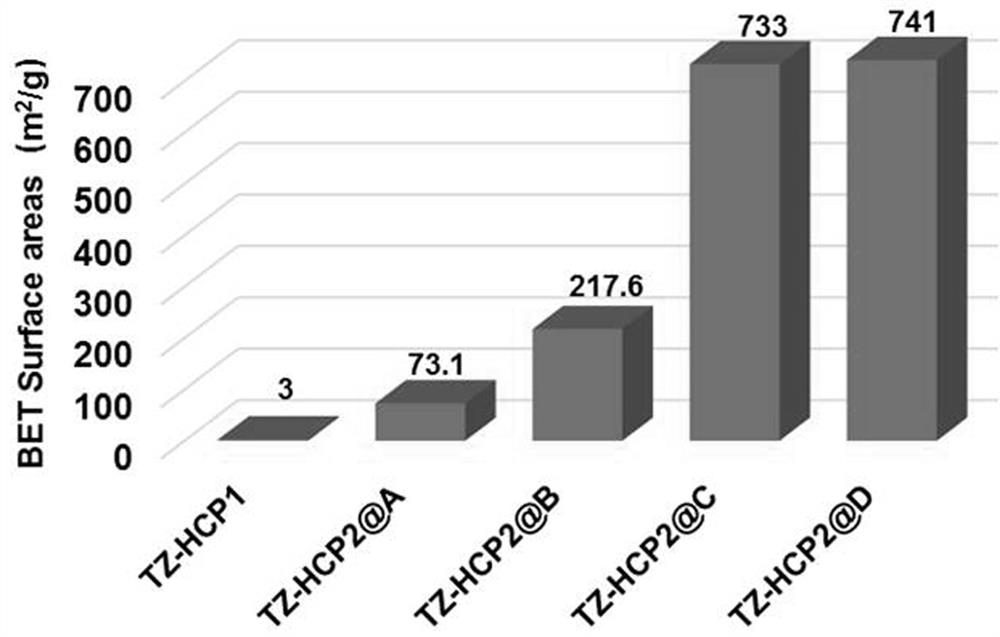

[0042] Place the methoxy-substituted bispyridine tetrazine monomer (165mg, 0.37mmol) and ferric chloride (2.4g, 14mmol) in a dry two-necked flask, vacuum 3-5 times under nitrogen protection, and then pass the needle Add 7.4mL of 1,2-dichloroethane into the flask, stir at room temperature for 0.5h, then add 1.33mL of dimethoxymethane into the flask, stir at 45°C for 5h, then raise the temperature to 90°C and continue the reaction for 19h. Then add 20mL of methanol to the flask, stir at 90°C for 0.5h, vacuum filter, wash with N,N-dimethylformamide and methanol, transfer the solid to the flask, add 20mL of concentrated hydrochloric acid, stir at room temperature for 2h, vacuum Suction filtration, after washing with N,N-dimethylformamide, methanol, and dichloromethane in sequence, the residue was subjected to Soxhlet extraction for 48 hours (methanol:dichloromethane=1:1), and dried in an oven to obtain the tetrazine Super-crosslinked porous photocatalyst TZ-HCP1 (brown black solid...

Embodiment 2

[0044] Place methoxy-substituted bispyridine tetrazine monomer (179mg, 0.4mmol) and iron trichloride (520mg, 3.2mmol) in a dry two-necked flask, vacuum 3-5 times under the protection of nitrogen, and then pour into the flask Add 1.6mL of 1,2-dichloroethane and 0.11mL of benzene, stir at room temperature for 0.5h, then add 0.29mL of dimethoxymethane into the flask, stir at 45°C for 5h, then raise the temperature to 90°C to continue the reaction for 19h. The reaction system was vacuum-filtered, washed successively with petroleum ether and acetone, the solid was transferred to a dry flask, 20 mL of hydrochloric acid (6M) was added, and stirred at room temperature for 2 h. Vacuum filtration, after washing with N,N-dimethylformamide, methanol and dichloromethane in sequence, Soxhlet extraction of the crude product with acetone as solvent for 48 hours, and drying in an oven at 80°C to obtain tetrazine supernatants Cross-linked porous photocatalyst TZ-HCP2@A (black solid powder) 241m...

Embodiment 3

[0046] Place methoxy-substituted bispyridine tetrazine monomer (103mg, 0.23mmol) and ferric trichloride (464mg, 2.86mmol) in a dry two-necked flask, evacuate 3-5 times under nitrogen protection, and then pour into the flask Add 1.43mL of 1,2-dichloroethane and 0.11mL of benzene, stir at room temperature for 0.5h, then add 0.26mL of dimethoxymethane into the flask, stir at 45°C for 5h, then raise the temperature to 90°C to continue the reaction for 19h. The reaction system was vacuum-filtered, washed successively with petroleum ether and acetone, the solid was transferred to a dry flask, 20 mL of hydrochloric acid (6M) was added, and stirred at room temperature for 2 h. Vacuum filtration, after washing with N,N-dimethylformamide, methanol and dichloromethane in sequence, Soxhlet extraction of the crude product with acetone as solvent for 48 hours, and drying in an oven at 80°C to obtain tetrazine supernatants Cross-linked porous photocatalyst TZ-HCP2@B (brown solid powder) 214m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com