PVD color-gradient coating technology for color-gradient cell phone rear cover

A mobile phone back cover and gradient color technology, which is applied in the direction of pretreatment surface, coating, and liquid coating device on the surface, etc., can solve the problems of difficult product quality, jagged patterns, waste, etc., and achieve rich patterns and colors. Guaranteed paint removal effect and improved paint removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

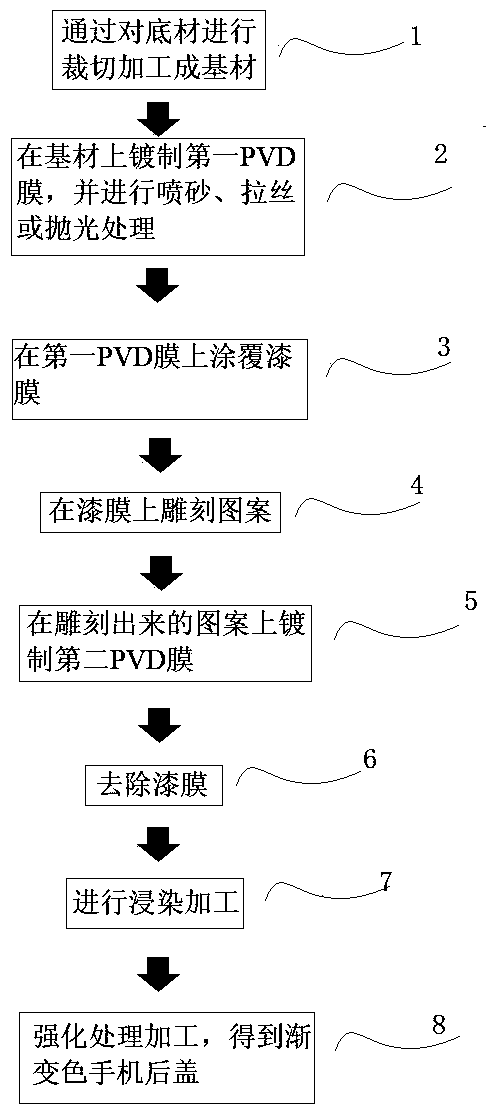

[0022] Examples, see attached figure 1 , a PVD gradient color coating process for the back cover of a gradient mobile phone, comprising the steps of:

[0023] 1) The base material is processed into a base material by cutting the base material, and the base material is a metal base material or a ceramic base material;

[0024] 2) The first PVD film is plated on the substrate by vacuum coating process: the surface of the substrate is sandblasted, brushed or polished;

[0025] 3) Coating a paint film on the first PVD film: coating the paint film by electrophoresis, spraying, dipping, rolling or brushing;

[0026] 4) Engraving patterns on the paint film, the engraving depth is greater than the thickness of the paint film: use a laser engraving machine to carve the pattern described on the paint film, and the pattern after the radium carving is a concave three-dimensional pattern;

[0027] 5) plate the second PVD film with a vacuum coating process on the carved pattern;

[0028]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com