Carbon quantum dot-CoFe type Prussian blue nanocomposite material as well as preparation method and application thereof

A nanocomposite material, Prussian blue-like technology, applied in the preparation/purification of carbon, manufacturing of hybrid/electric double layer capacitors, and compounding cyanide, etc., can solve the problem of poor rate performance of Prussian blue-like compounds, limiting the application of supercapacitors, Unsatisfactory rate performance and other issues, to achieve the effect of improving fast charge and discharge and cycle life, improving electronic conductivity, and high rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

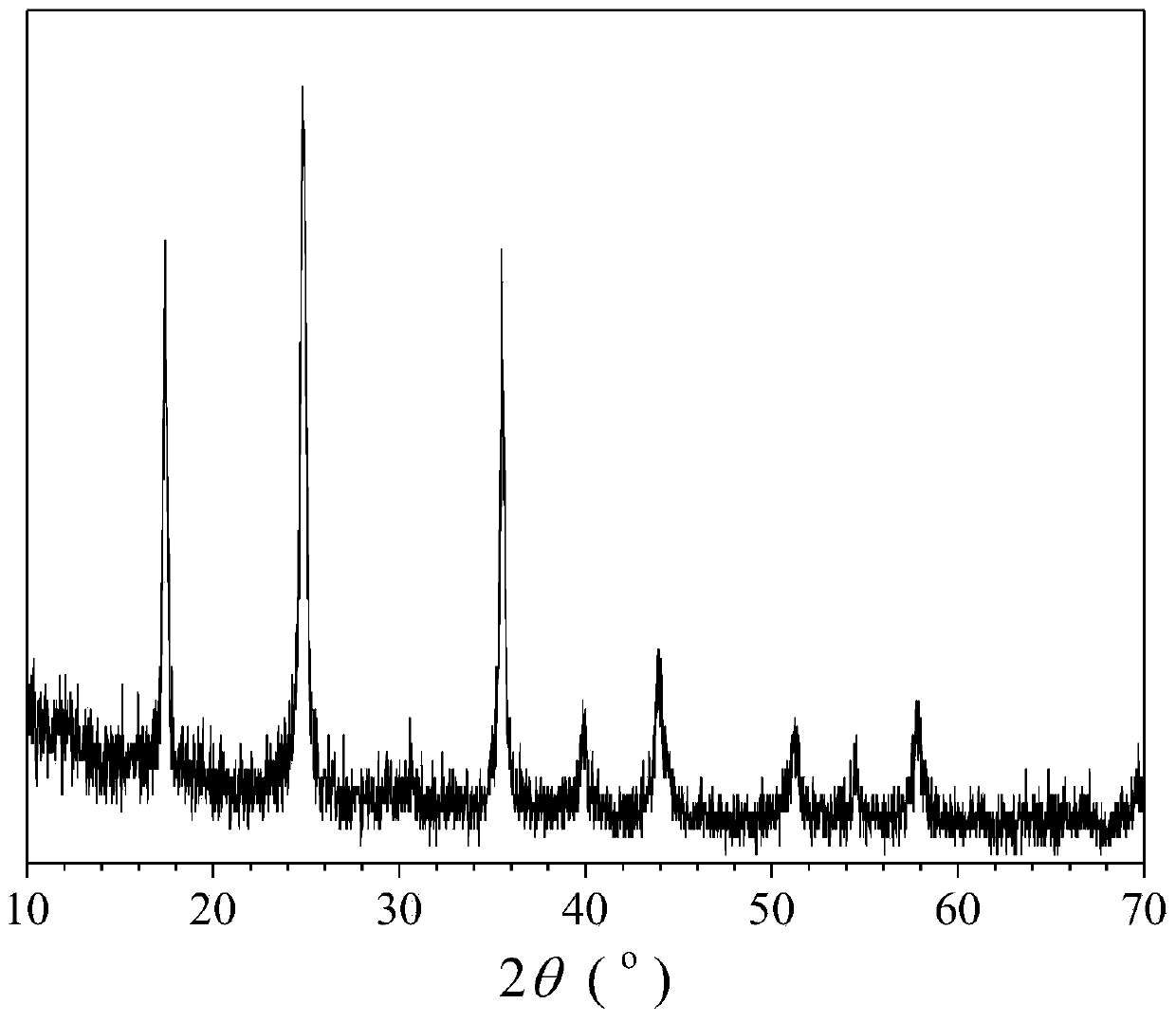

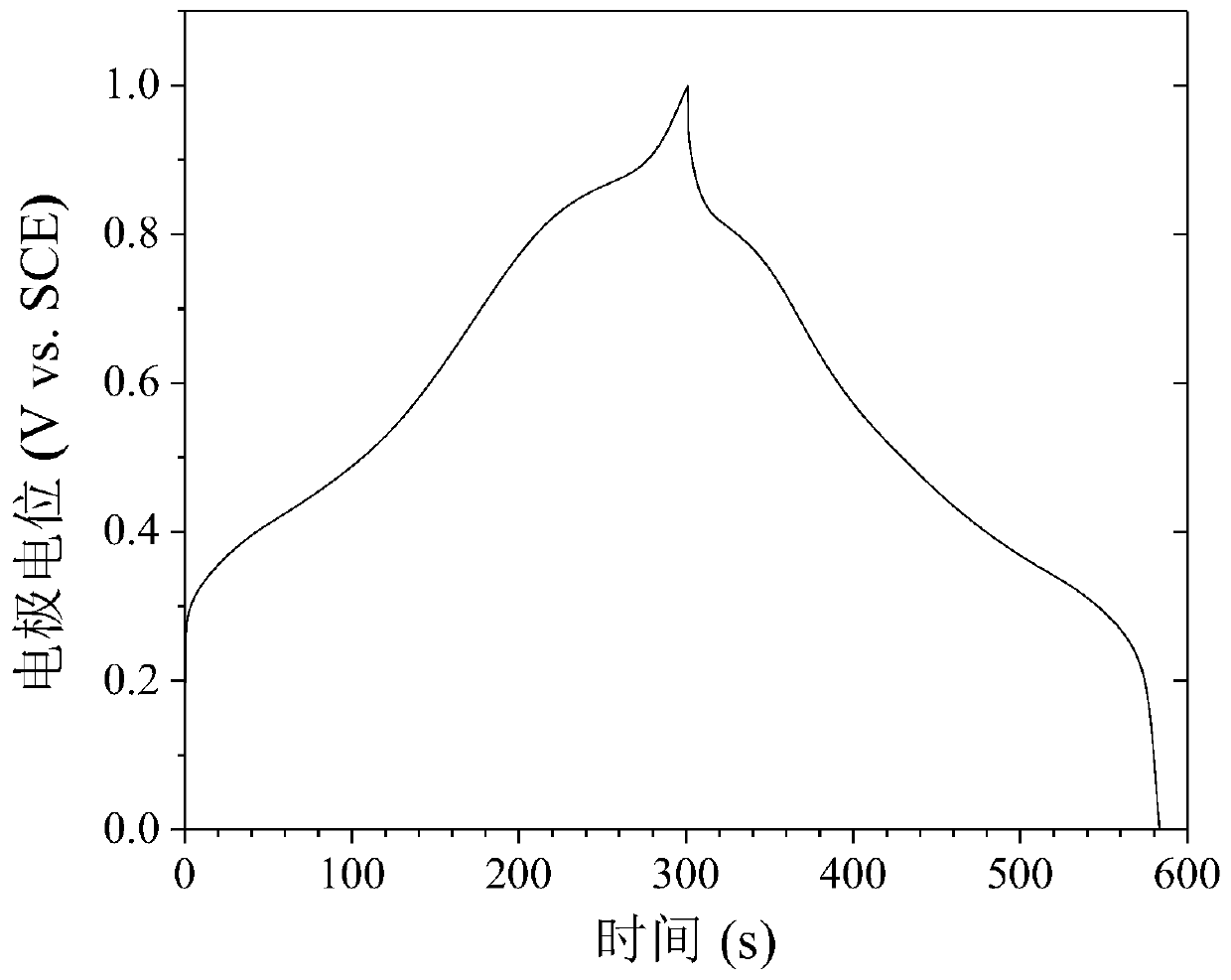

[0034] Take by weighing 2g potassium citrate and be dissolved in 20mL deionized water and be mixed with potassium citrate solution, transfer in the hydrothermal synthesizer, heat 180 degrees Celsius, the time obtains carbon quantum dot solution in 3 hours; Then take by weighing 0.146g cobalt nitrate hexahydrate ( 0.5mmol) was dissolved in the carbon quantum dot solution to prepare a carbon quantum dot-cobalt nitrate mixed solution, and the concentration of cobalt nitrate hexahydrate was 0.025mol / L; then weighed 0.099g potassium ferricyanide (0.3mmol) and dissolved it in 20mL Potassium ferricyanide solution was prepared in deionized water; under stirring, the potassium ferricyanide solution was slowly added dropwise to the carbon quantum dot-cobalt nitrate mixed solution, the stirring was stopped, and the room temperature was left to age for 24 hours; the sample was filtered, and the deionized Washed three times with deionized water and dried at 90°. from figure 1 with figur...

Embodiment 2

[0038] Take by weighing 4g potassium citrate and be dissolved in 20mL deionized water and be mixed with potassium citrate solution, transfer in the hydrothermal synthesizer, heat 200 degrees Celsius, the time obtains carbon quantum dot solution in 5 hours; Then take by weighing 0.175g cobalt nitrate hexahydrate ( 0.6mmol) is dissolved in carbon quantum dot solution and is mixed with carbon quantum dot-cobalt nitrate mixed solution, and the concentration of cobalt nitrate hexahydrate is 0.03mol / L; Then weigh 0.132g potassium ferricyanide (0.4mmol) and dissolve in 20mL Potassium ferricyanide solution was prepared in deionized water; under stirring, the potassium ferricyanide solution was slowly added dropwise to the carbon quantum dot-cobalt nitrate mixed solution, the stirring was stopped, and the room temperature was left to age for 18 hours; the sample was filtered, and the deionized Washed 5 times with deionized water and dried at 60°C. from Figure 5 with Image 6 A carbo...

Embodiment 3

[0042] Take by weighing 6g potassium citrate and be dissolved in 20mL deionized water and be mixed with potassium citrate solution, transfer in the hydrothermal synthesizer, heat 190 degrees Celsius, the time obtains carbon quantum dot solution in 6 hours; Then take by weighing 0.291g cobalt nitrate hexahydrate ( 1mmol) is dissolved in carbon quantum dot solution and is mixed with carbon quantum dot-cobalt nitrate mixed solution, and the concentration of cobalt nitrate hexahydrate is 0.05mol / L; Then weigh 0.165g potassium ferricyanide (0.5mmol) and dissolve in 20mL to Potassium ferricyanide solution was prepared in deionized water; under stirring, the potassium ferricyanide solution was slowly added dropwise into the carbon quantum dot-cobalt nitrate mixed solution, the stirring was stopped, and it was aged at room temperature for 24 hours; the sample was filtered and deionized using Wash 4 times with water and dry at 70°. from Figure 9 with Figure 10 A carbon quantum dot-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com