Graphene modified conductive polystyrene composite material for precision electronic carrier tape and preparation method thereof

A composite material and polystyrene technology, applied in the chemical field, can solve problems such as electronic carrier needs to be improved, molding shrinkage strength, toughness, surface crystal point surface resistance uniformity is difficult to meet the use requirements, carbon deposition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

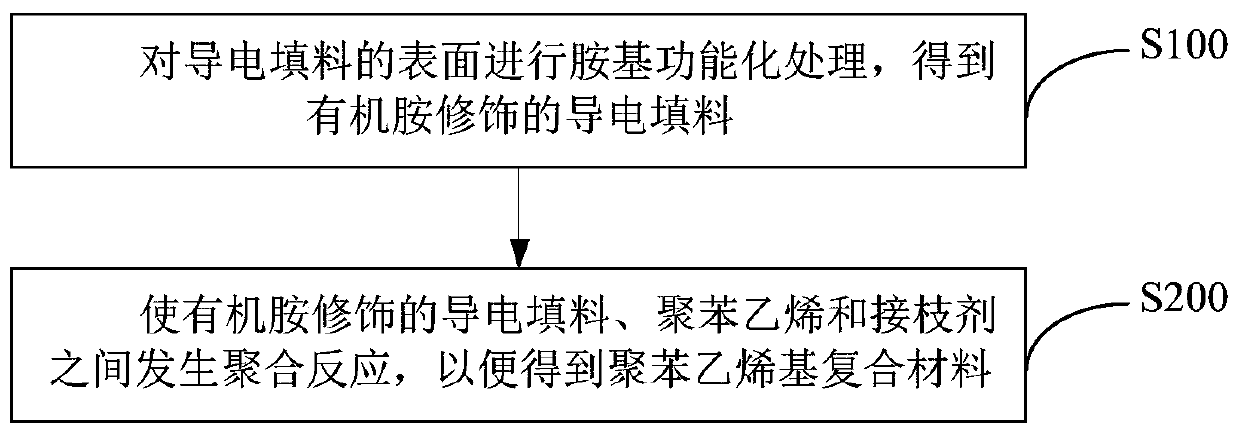

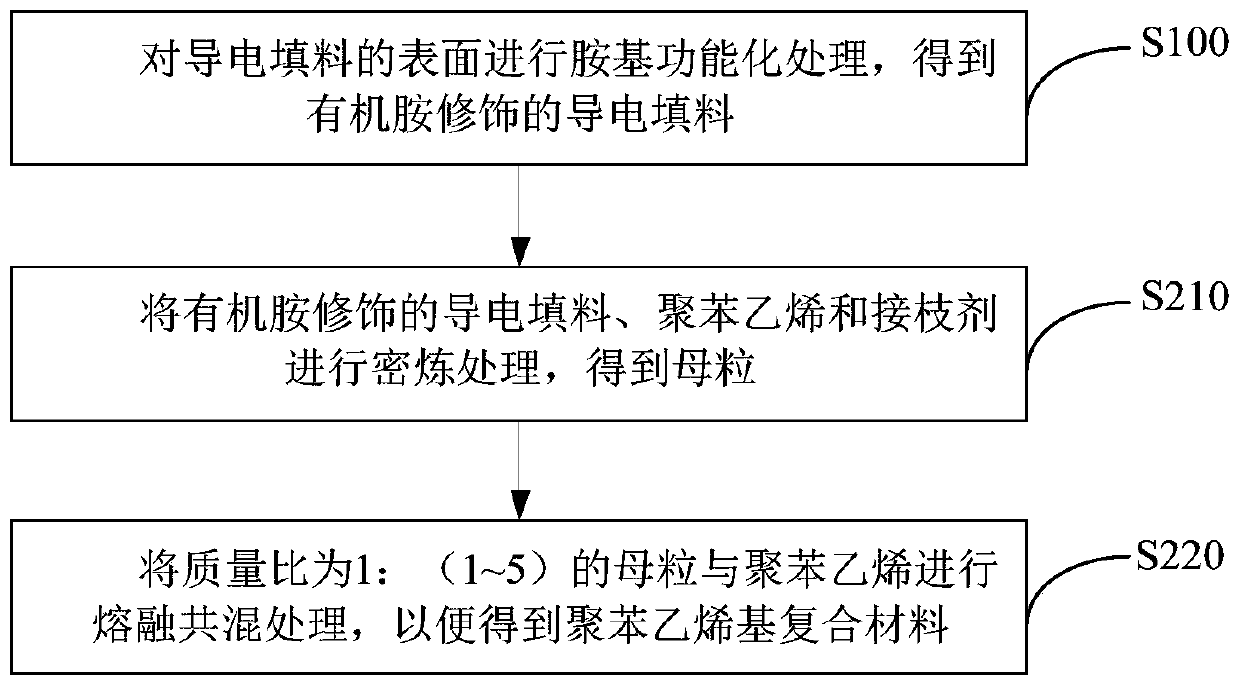

Method used

Image

Examples

Embodiment 1

[0078] Graphene was used as the main raw material to add hydrogen peroxide and ferrous ions for mild oxidation treatment, the mass ratio of the three was 2:4:2, and stirred at 90°C for 2 hours.

[0079] Put the obtained products into several centrifuge bottles respectively. Do not overfill the graphene solution to prevent liquid splashing during the centrifugation process. Then put the centrifuge bottles into the centrifuge. The centrifuge speed is set at 9000rpm, and the centrifugation time is controlled at about 5min. , then remove the supernatant, wash with deionized water or other organic solvents, and filter until neutral, put it in a drying oven for drying, the temperature of the drying oven can be adjusted to 100°C, dry for 4 hours, and then you can get Graphene oxide with a small amount of hydroxyl or epoxy groups.

[0080] Then put graphene oxide into octadecylamine and formaldehyde solvent, the volume ratio can be set to 1:5:20, ultrasonically disperse for 1 hour, an...

Embodiment 2

[0093] Graphene was used as the main raw material to add hydrogen peroxide and ferrous ions for mild oxidation treatment, the mass ratio of the three was 2:4:2, and stirred at 90°C for 2 hours.

[0094] Put the obtained products into several centrifuge bottles respectively. Do not overfill the graphene solution to prevent liquid splashing during the centrifugation process. Then put the centrifuge bottles into the centrifuge. The centrifuge speed is set at 9000rpm, and the centrifugation time is controlled at about 5min. , then remove the supernatant, wash with deionized water or other organic solvents, and filter until neutral, put it in a drying oven for drying, the temperature of the drying oven can be adjusted to 100°C, dry for 4 hours, and then you can get Graphene oxide with a small amount of hydroxyl or epoxy groups.

[0095] Then put graphene oxide into octadecylamine and formaldehyde solvent, the volume ratio can be set to 1:5:20, ultrasonically disperse for 1 hour, an...

Embodiment 3

[0108] Graphene was used as the main raw material to add hydrogen peroxide and ferrous ions for mild oxidation treatment, the mass ratio of the three was 2:4:2, and stirred at 90°C for 2 hours.

[0109] Put the obtained products into several centrifuge bottles respectively. Do not overfill the graphene solution to prevent liquid splashing during the centrifugation process. Then put the centrifuge bottles into the centrifuge. The centrifuge speed is set at 9000rpm, and the centrifugation time is controlled at about 5min. , then remove the supernatant, wash with deionized water or other organic solvents, and filter until neutral, put it in a drying oven for drying, the temperature of the drying oven can be adjusted to 100°C, dry for 4 hours, and then you can get Graphene oxide with a small amount of hydroxyl or epoxy groups.

[0110] Then put graphene oxide into octadecylamine and formaldehyde solvent, the volume ratio can be set to 1:5:20, ultrasonically disperse for 1 hour, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Charpy notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com