Lithium-ion battery and manufacturing method thereof

A technology of lithium-ion battery and manufacturing method, which is applied in the field of high-safety lithium-ion battery and its manufacturing, can solve problems such as inability to prevent thermal runaway, and achieve the effect of simple coating and low cost of materials and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

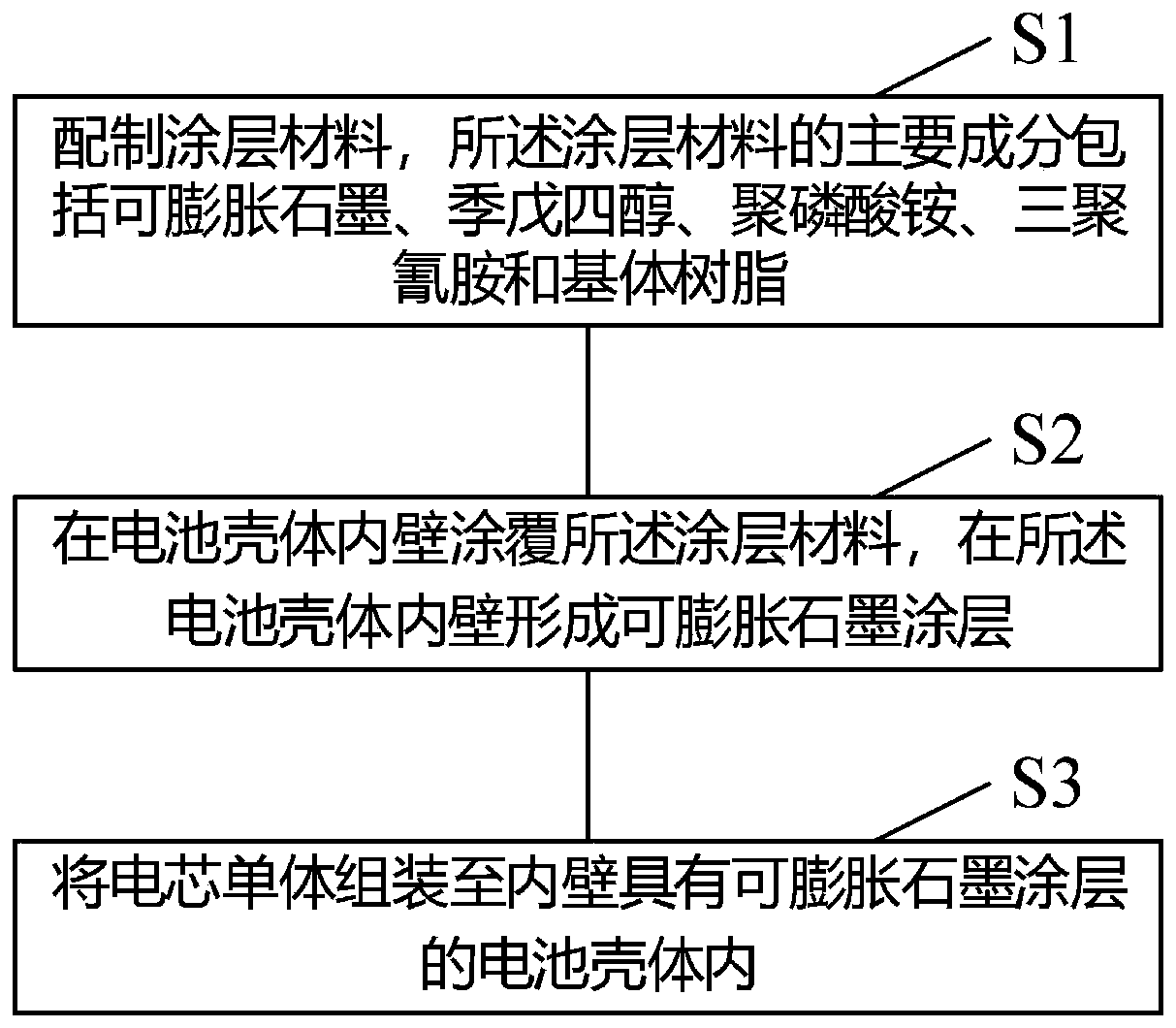

[0046] Step S1, preparing paint: Mix pentaerythritol, ammonium polyphosphate, melamine, and matrix resin with a high-speed electric mixer for 20 minutes, add expandable graphite, dispersant, and defoamer, continue mixing until uniform, and then set aside for use. Wherein the material ratio is: expandable graphite: pentaerythritol: ammonium polyphosphate: melamine: matrix resin: dispersant: defoamer = 12%: 18%: 20%: 12%: 35%: 2%: 1%.

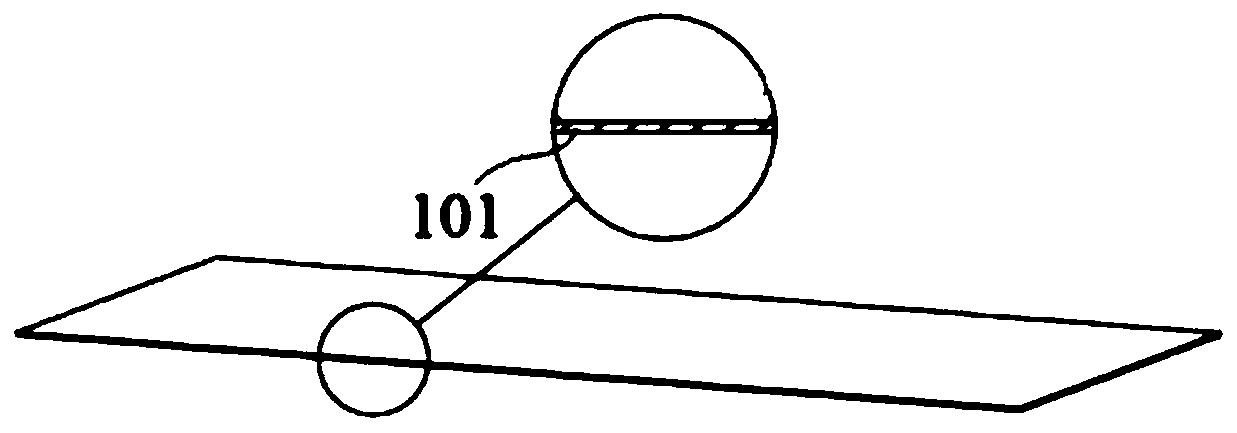

[0047] Step S2, shell coating: after removing the oxide film inside the battery shell, paint the prepared paint on the inner wall of the battery shell, let it dry naturally at room temperature, repeat the brushing and dry after drying, until the expandable graphite coating When the thickness reaches 4mm, put it in a constant temperature box at 45°C for 24 hours. The function of keeping it warm is to completely remove the moisture that may exist in the coating, so as to avoid the performance degradation of the battery caused by the introduction of ...

Embodiment 2

[0051] Step S1, preparing paint: Mix pentaerythritol, ammonium polyphosphate, melamine, and matrix resin with a high-speed electric mixer for 20 minutes, add expandable graphite, dispersant, and defoamer, continue mixing until uniform, and then set aside for use. Wherein the material ratio is: expandable graphite: pentaerythritol: ammonium polyphosphate: melamine: matrix resin: dispersant: defoamer = 14%: 18%: 18%: 10%: 37%: 2%: 1%.

[0052] Step S2, shell coating: after removing the oxide film inside the battery shell, paint the prepared paint on the inner wall of the battery shell, let it dry naturally at room temperature, repeat the brushing and dry after drying, until the expandable graphite coating When the thickness reaches 3mm, put it in a thermostat at 45°C for 24 hours.

[0053] Step S3, battery cell assembly: After putting the battery cells into the shell, inject liquid, seal, stand still, form, charge at 0.5C to 4.2V, cut off the current at 0.05C, and complete the b...

Embodiment 3

[0056] Step S1, preparing paint: Mix pentaerythritol, ammonium polyphosphate, melamine, and matrix resin with a high-speed electric mixer for 20 minutes, add expandable graphite, dispersant, and defoamer, continue mixing until uniform, and then set aside for use. Wherein the material ratio is: expandable graphite: pentaerythritol: ammonium polyphosphate: melamine: matrix resin: dispersant: defoamer = 12%: 18%: 20%: 12%; 35%: 2%: 1%.

[0057] Step S2, shell coating: after removing the oxide film inside the battery shell, paint the prepared paint on the inner wall of the battery shell, let it dry naturally at room temperature, repeat the brushing and dry after drying, until the expandable graphite coating When the thickness reaches 2mm, put it in a thermostat at 45°C for 24 hours.

[0058] Step S3, battery cell assembly: After putting the battery cells into the shell, inject liquid, seal, stand still, form, charge 4.2V at 0.5C, cut off the current at 0.05C, and complete the batt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com