Alkyl-modified carboxyl group-containing copolymer, thickener containing said copolymer, and method for preparing said copolymer

A technology of alkyl modification and copolymer, which is applied in medical preparations containing active ingredients, preparations for skin care, chemical instruments and methods, etc. Insufficient properties, etc., to achieve the effect of excellent dispersibility and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

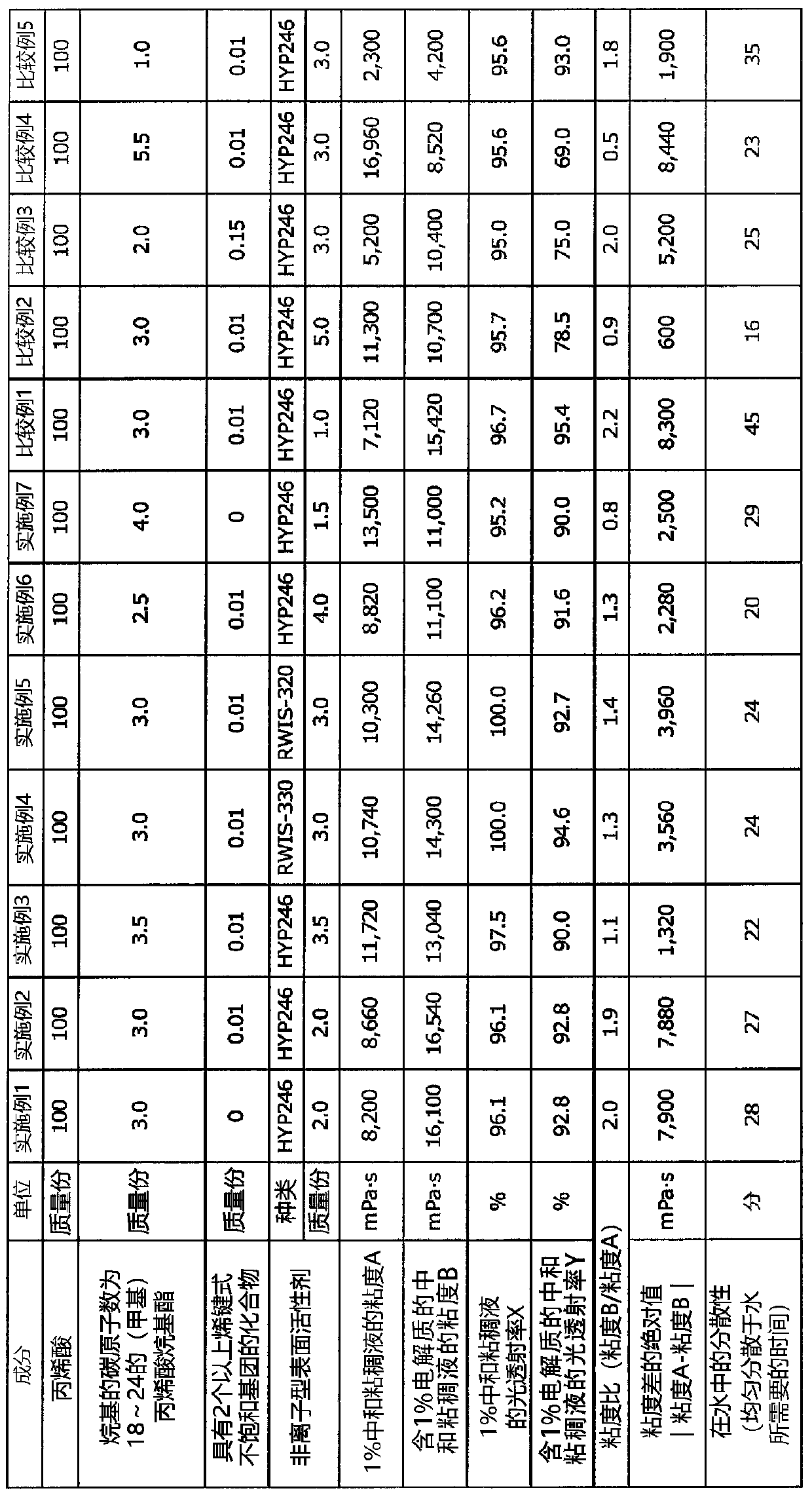

Examples

Embodiment 1

[0075] In a four-neck flask with a capacity of 500 mL (milliliters) equipped with a stirrer, a thermometer, a nitrogen gas blowing tube, and a condenser tube, 45 g of acrylic acid and an alkyl (meth)acrylate having 18 to 24 carbon atoms as an alkyl group were added. BLEMMER VMA70 (manufactured by NOF Corporation, 10-20 parts by mass of stearyl methacrylate, 10-20 parts by mass of eicosyl methacrylate, 59-80 parts by mass of behenyl methacrylate, and 59-80 parts by mass of behenyl methacrylate) 1.35 g of tetracosyl acrylate content of 1% by mass or less), 0.116 g of 2,2'-azobis(methyl isobutyrate) as a radical polymerization initiator, and 230.9g of n-hexane. Next, after stirring and mixing the solution uniformly, nitrogen gas was blown into the solution in order to remove oxygen present in the upper space of the reaction container (four-necked flask), the raw materials, and the reaction solvent. Next, the solution was heated to 60-65° C. under a nitrogen atmosphere. Two hour...

Embodiment 2

[0077] In Example 1, when adding the raw material before heating, 0.0045 g of pentaerythritol polyallyl ether as a compound having at least two ethylenically unsaturated groups was added, and the procedure was carried out in the same manner as in Example 1, 43 g of white fine particles of the alkyl-modified carboxyl group-containing copolymer were obtained.

Embodiment 3

[0079] In Example 2, BLEMMER VMA70 (manufactured by NOF Corporation, 10 to 20 parts by mass of stearyl methacrylate, 10 to 20 parts by mass of eicosyl methacrylate of behenyl methacrylate was 59 to 80 parts by mass and a mixture with a content of tetracosyl methacrylate of 1 mass % or less) was changed to 1.575 g, and the block of 12-hydroxystearic acid and polyethylene oxide Except having changed the usage-amount of a copolymer (manufactured by Croda, Hypermer B246) to 1.575 g, it carried out similarly to Example 2, and obtained 42 g of white fine particles of an alkyl-modified carboxyl group-containing copolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com