Weather-resistant and high-ductility finish paint

A ductile and weather-resistant technology, applied in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of large solvent volatilization, harmful to human health, and large VOC release, and achieve excellent tensile properties and dryness Fast speed and strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

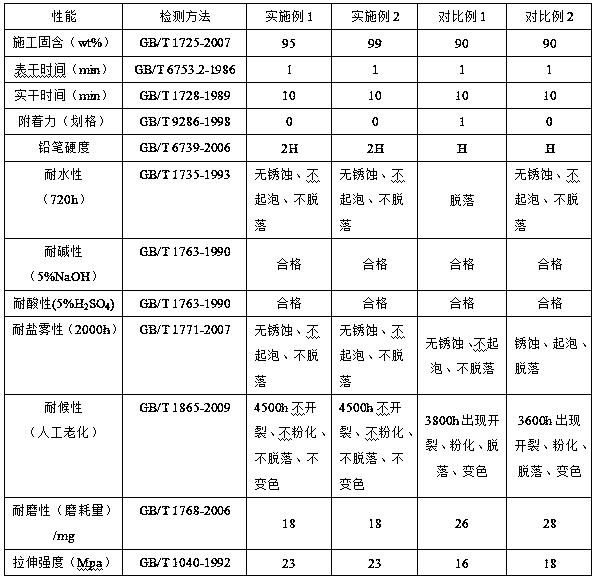

Examples

Embodiment 1

[0052] A weather-resistant, highly ductile topcoat comprising the following components in weight percent:

[0053] White pulp 78.2%

[0054] Black pulp 18.3%

[0055] Silicone leveling agent BYK331 0.2%

[0056] Acrylic leveling agent BYK354 0.5%

[0057] Ultraviolet light absorber TINUVIN 1130 1.0%

[0058] Light stabilizer TINUVIN 292 0.5%

[0059] Adhesion Promoter 1.3%

[0060] Among them, the adhesion promoter is the 2802 water-based epoxy phosphate baking paint adhesion promoter of Shenzhen Haineng Chemical Co., Ltd.

[0061] White pulp comprises the following components in weight percentage:

[0062] Titanium dioxide R902 66.0%

[0063] Dispersant BYK-110 1.0%

[0064] Polyaspartic resin 33.0%

[0065] The black slurry comprises the following components in weight percentage:

[0066] Carbon black FW200 12.0%

[0067] Dispersant BYK-163 12.0%

[0068] Polyaspartic resin 76.0%

[0069] A method for preparing a weather-resistant, high-extensibility topcoat, sp...

Embodiment 2

[0074] A weather-resistant, highly ductile topcoat comprising the following components in weight percent:

[0075] White pulp 80%

[0076] Black Pulp 17%

[0077] Silicone leveling agent BYK331 0.2%

[0078] Acrylic leveling agent BYK354 0.3%

[0079] Ultraviolet light absorber TINUVIN 1130 0.5%

[0080] Light stabilizer TINUVIN 292 0.5%

[0081] Adhesion Promoter 1.5%

[0082]Among them, the adhesion promoter is the 2802 water-based epoxy phosphate baking paint adhesion promoter of Shenzhen Haineng Chemical Co., Ltd.

[0083] White pulp comprises the following components in weight percentage:

[0084] Titanium dioxide R902 60%

[0085] Dispersant BYK-110 1.5%

[0086] Polyaspartic resin 32.5%

[0087] The black slurry comprises the following components in weight percentage:

[0088] Carbon black FW200 10%

[0089] Dispersant BYK-163 10%

[0090] Polyaspartic resin 80%

[0091] A method for preparing a weather-resistant, high-extensibility topcoat, specifically co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com