Manganese dioxide-porous carbon composite material as well as preparation method and application thereof

A manganese dioxide, composite material technology, applied in nanotechnology for materials and surface science, hybrid capacitor electrodes, nanotechnology, etc., can solve problems such as low conductivity, reduce structural damage, easy experimental conditions, and package. Even coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] Take 0.03g of porous carbon, ultrasonically disperse in 30ml of water for 30 minutes, KMnO 4 and Na 2 SO 4 Add it to the porous carbon suspension at a concentration of 0.2 mol / L, stir vigorously for 16 hours, filter, wash the obtained product with distilled water, and dry it under vacuum at 150°C.

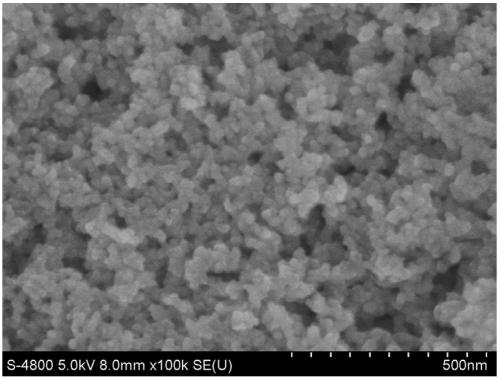

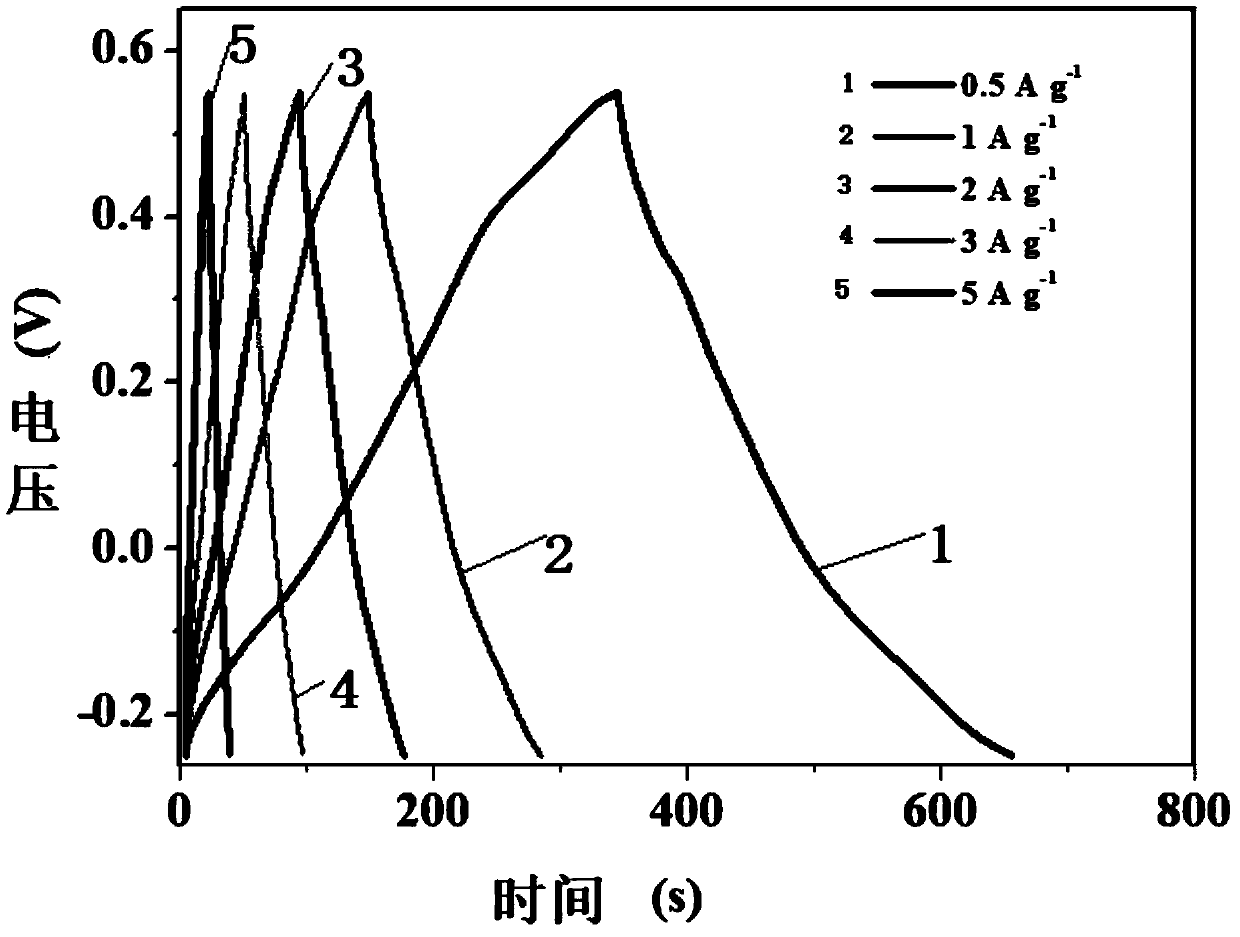

[0022] The morphology of the prepared product sample was observed by scanning electron microscope. figure 1 It can be seen that MnO 2 The 30nm spherical structure is attached to the porous carbon surface. This product was applied to supercapacitor electrode materials for electrochemical characterization. figure 2 It can be seen that at 0.5A·g -1 Under the current density, its capacity can be stabilized at 215F·g -1 .

example 2

[0024] Take 0.03g of porous carbon, ultrasonically disperse in 30ml of water for 30 minutes, KMnO 4 and Na 2 SO 4 Add it to the porous carbon suspension at a concentration of 0.3 mol / L, stir vigorously for 8 hours, filter, wash the obtained product with distilled water, and dry it under vacuum at 150°C.

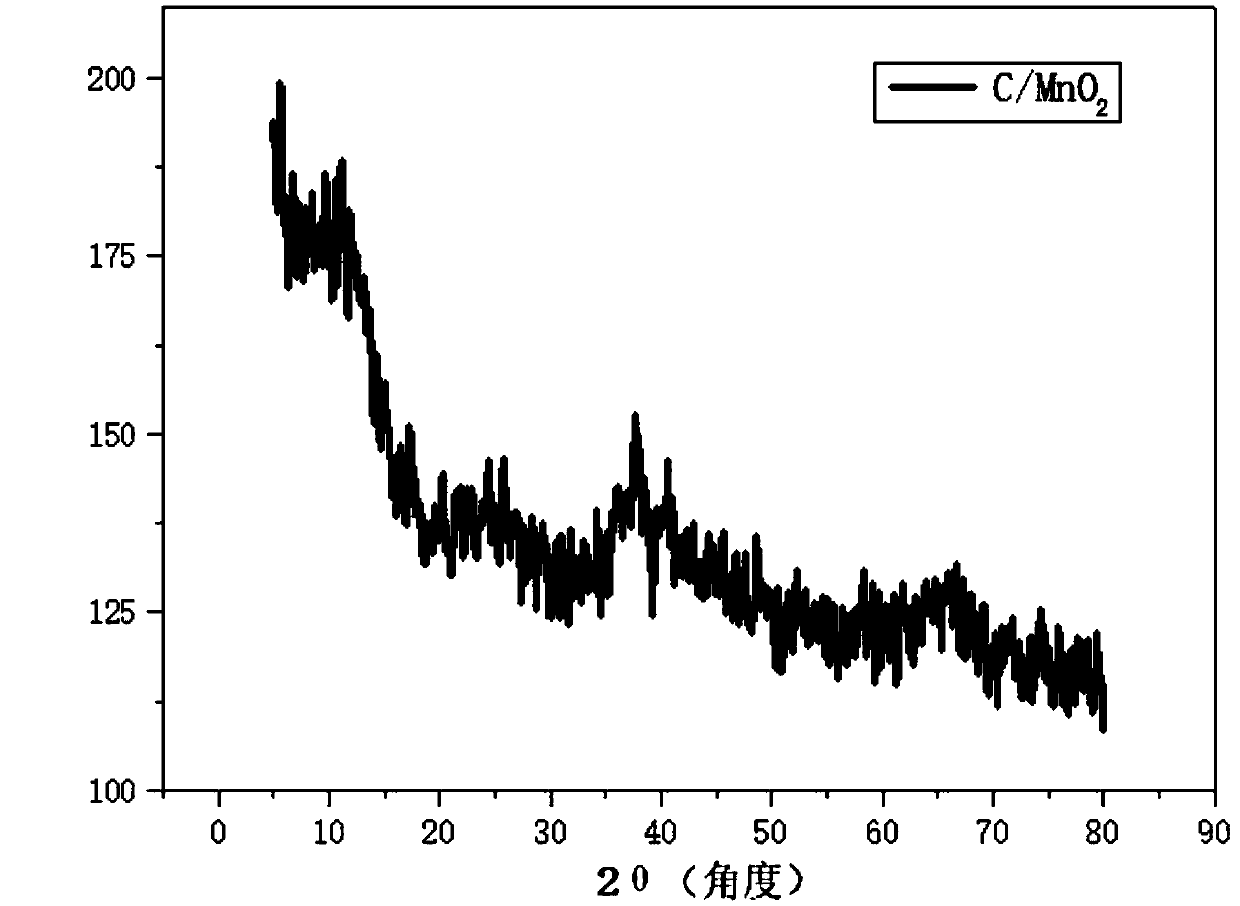

[0025] Using a scanning electron microscope to observe the morphology of the prepared product samples, it can be seen that the MnO 2 It is a spherical structure attached to the surface of porous carbon. attached image 3 is its X-ray diffraction pattern, where 2θ is 12.7°, 18.1°, 28.7°, 37.5°, 41.8°, 49.8°, 60.1° and 69.5°, the corresponding diffraction peaks are consistent with the standard card JCPDS00-044-0141, corresponding to On the (110), (200), (310), (211), (301), (411), (521) and (541) crystal planes, the composite structure of porous carbon and manganese dioxide was confirmed. This product was applied to supercapacitor electrode materials for electrochemical ch...

example 3

[0027] Take 0.03g of porous carbon, ultrasonically disperse in 30ml of water for 30 minutes, KMnO 4 and Na 2 SO 4 Add it to the porous carbon suspension at a concentration of 0.1 mol / L, stir vigorously for 3 hours, filter, wash the obtained product with distilled water, and dry it under vacuum at 150°C.

[0028] The morphology of the prepared product sample was observed by scanning electron microscope. Figure 4 It can be seen that MnO 2 It is a spherical structure attached to the surface of porous carbon. This product was applied to supercapacitor electrode materials for electrochemical characterization. -1 Under the current density, its capacity can be stabilized at 181F g -1 .

[0029] It can be seen from the above three examples that KMnO 4 and Na 2 SO 4 The concentration is critical. When KMnO 4 and Na 2 SO 4 The concentration is too low, the reduced MnO 2 If the particle size is too small, the capacity of the assembled supercapacitor will be low. When KMnO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com