Wet storage processing method of high-moisture corn

A processing method and high-moisture technology, applied in food processing, edible seed preservation, bacteria used in food preparation, etc., can solve the problems of corn kernel processing and storage difficulties, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

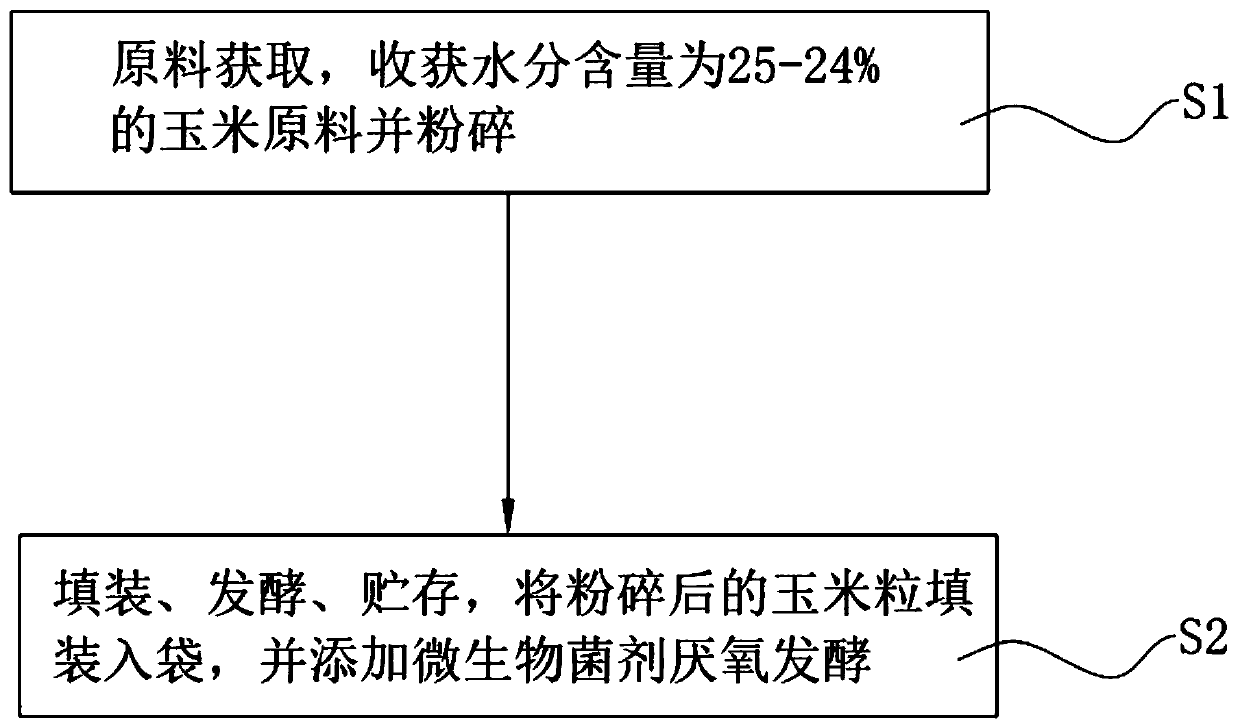

[0024] like figure 1 As shown, the embodiment of the present invention provides a kind of wet storage processing method of high-moisture corn, comprising:

[0025] S1. Raw material acquisition

[0026] A number of corn cobs or corn kernels with a moisture content of 25-45% are harvested, and the harvested corn material is ground.

[0027] Wherein, in the present invention, after the corn maturity reaches 25-40% of the water content, the corn combine harvester is used to harvest in advance, and the harvested corn raw material is transported to the special double-shaft pulverizer of HRT Xili for crushing, so that the corn raw material After being crushed by the upper rotor of the high-speed pulverizer, it is crushed again by the hammer of the rapidly rotating lower rotor. At the same time, the materials in the inner cavity collide with each other rapidly and crush each other to achieve the effect of hammer powder and material powder, which can crush corn raw materials. into pa...

Embodiment 2

[0045] The difference from Example 1 is that in the process of filling corn kernels, the pulverized corn kernels are first filled into fermentation bags in batches, and microbial agents are added in the fermentation bags at the same time. Finally, it is compacted, and the mouth of the bag is tightly sealed for anaerobic fermentation. By filling the crushed corn kernels into bags first and then compacting them, the filling of corn lumps and the sealing and molding of corn kernels can be completed quickly, and only the corn kernels filled into bags are put into the warehouse in batches and stored In about 3 weeks, the fermented corn can reach a stable state, can be fed and stored for a long time, is easy to operate, does not require a professional reserve with huge investment, and the storage cost is very low, about one-twentieth of the cost of professional grain storage. Moreover, if the package is not damaged, the storage is very safe, and it will not be corrupted for at least...

Embodiment 3

[0047] The difference from Example 1 is that because the moisture content of the crushed corn kernels is too low to be conducive to fermentation, before the crushed corn kernels are filled, the moisture content of the crushed corn kernels is measured by using a DSH series moisture quick tester. For the corn grains whose water content is lower than the range value of the harvested water content, an aqueous solution is added in a predetermined proportion to adjust the water content of the crushed corn to the value within the range value of the harvested water content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com