Vanadium ore beneficiation method

A mineral processing method and vanadium ore technology, applied in the field of vanadium ore dressing, can solve the problems of large environmental pollution, high roasting cost, no profit space, etc., and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

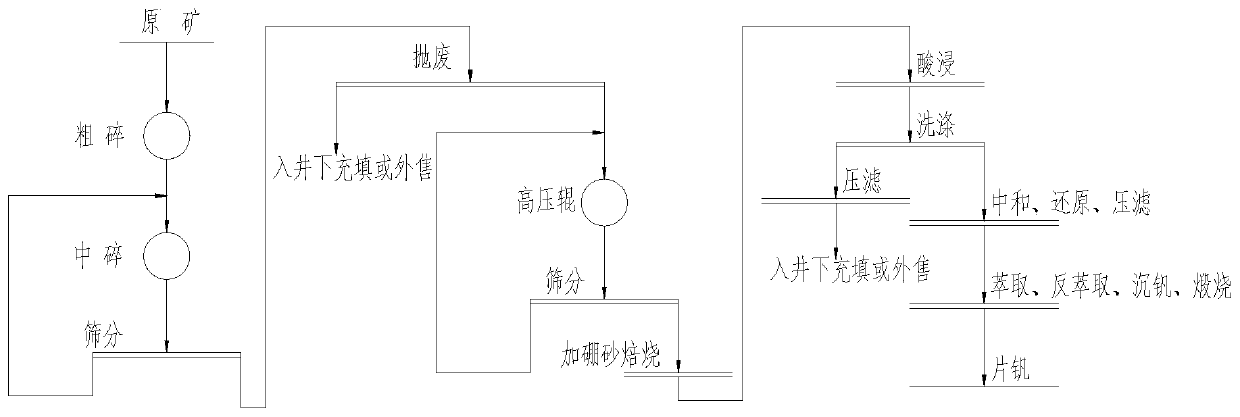

Method used

Image

Examples

Embodiment 1

[0022] In this embodiment, a stone coal vanadium mine in a certain place in Hubei is taken as an example, and the vanadium content of the raw ore is 0.8%.

[0023] 1) The stone coal vanadium ore is crushed in two stages and one closed circuit until the average particle size is 30mm, and then the crushed ore is discarded by an optical separator, the discarding rate reaches 25%, and the ore recovery rate is 95%; In the waste ore, the content of vanadium is enriched to 1.45%; the thrown gangue is directly sent to the underground for filling.

[0024] 2) Use the patent of Changsha Nonferrous Metallurgical Design and Research Institute Co., Ltd. (China Invention Authorization CN201310602621.2) to crush the discarded ore, that is, use a high-pressure roller mill in a closed circuit to crush it to an average particle size of 3mm.

[0025] 3) Add 3% borax relative to the total mass of the ore to the crushed ore, and after mixing, use a fluidized bed furnace to decarburize and roast fo...

Embodiment 2

[0027] In this embodiment, a stone coal vanadium mine in a certain place in Hubei is taken as an example, and the ore contains 0.6% vanadium.

[0028] 1) The stone coal vanadium ore is crushed in two stages and one closed circuit until the average particle size is 20mm, and then the crushed ore is discarded by an optical separator, the discarding rate reaches 30%, and the ore recovery rate is 90%; In the waste ore, the content of vanadium is enriched to 1.38%; the thrown gangue is directly sent to the underground for filling.

[0029] 2) Use the patent of Changsha Nonferrous Metallurgical Design and Research Institute Co., Ltd. (China Invention Authorization CN201310602621.2) to crush the discarded ore, that is, use a high-pressure roller mill to crush it in a closed circuit until the average particle size is 5mm.

[0030] 3) Add borax that is 5% relative to the total mass of ore in the crushed ore, and after mixing, use a fluidized bed furnace to carry out decarburization and...

Embodiment 3

[0032] In this embodiment, taking a stone coal vanadium mine in a certain place in Hubei as an example, the vanadium content of the raw ore is 1.4%.

[0033] 1) The stone coal vanadium ore is crushed in two stages and one closed circuit until the average particle size is 50mm, and then the crushed ore is discarded by an optical separator. The discarding rate reaches 20%, and the ore recovery rate is 93%; In the waste ore, the content of vanadium is enriched to 1.97%; the thrown gangue is directly sent to the underground for filling.

[0034] 2) Use the patent of Changsha Nonferrous Metallurgical Design and Research Institute Co., Ltd. (China Invention Authorization CN201310602621.2) to crush the discarded ore, that is, use a high-pressure roller mill in a closed circuit to crush the average particle size to 1.5mm.

[0035] 3) Add 2% borax relative to the total mass of the ore to the crushed ore, and after mixing, use a fluidized bed furnace to decarburize and roast at 850°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com