Method and device for dry-type medium- and high-temperature grading electrofiltration dust removal of carbon thermal reduction furnace flue gas

A reduction furnace, medium and high temperature technology, applied in the field of high temperature graded electric filter dust removal, to achieve the effect of preventing condensation and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

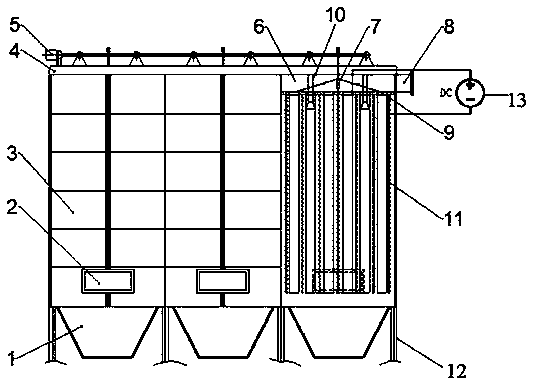

[0029] Embodiment 1: as figure 1 , 2 As shown, the device used in this embodiment includes 3 dust removal units, a blower 5, an insulating support 12, and a high-voltage power supply 13, wherein the dust removal unit includes an insulating shell 3, an air outlet channel 6, an insulating fixing bracket 7, a high-temperature electric heating electric filter Coupling assembly 9, cathode electrode 11, nozzle 10, insulating fixing bracket 7 are fixed below the fixing plate 4 on the top of the insulating shell 3, six high-temperature electric heating and electric filter coupling assemblies 9 are fixed under the insulating fixing bracket 7, and three cathode electrodes 11 Fixed on the insulating fixing bracket 7 and located around the high-temperature electric heating electric filter coupling assembly, two nozzles 10 are fixed under the fixing plate 4 and above the high-temperature electric heating electric filter coupling assembly 9, between the fixing plate 4 and the insulating fix...

Embodiment 2

[0031] Embodiment 2: The structure of the device used in this embodiment is the same as in Embodiment 1;

[0032] Pass the high-dust yellow phosphorus vapor at 150°C into the insulating shell 3 through the air inlet 2, in which the gas flow velocity is 15m / s, and the particle concentration is 60mg / m 3 , the oxygen content is lower than 4%; the cathode electrode 11 in the charging area adopts a conical grid electrode, the electrode material is silicon carbide, and the anode electrode is a high-temperature electric heating electric filter coupling assembly 9, which is made of aluminum alloy as a hollow cylinder , and then the cylinder is drilled with a laser to form micropores with a pore size of 60 μm; and the cathode and anode are connected to a 100kv AC high-voltage power supply 13, and the heating temperature of the high-temperature electric heating and electric filter coupling assembly 9 is 400°C; the gas Enter the charging area from the air inlet 2, and charge the particle...

Embodiment 3

[0034] Embodiment 3: The structure of the device used in this embodiment is the same as in Embodiment 1;

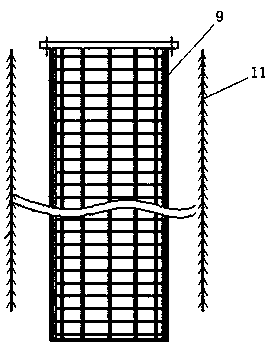

[0035] The 500°C copper smelting acid production flue gas is passed into the insulating shell 3 through the air inlet 2, where the flue gas flow rate is 10m / s, and the concentration of particulate matter in the flue gas is 200 mg / cm 3 , the flue gas also contains some gaseous heavy metal substances, such as As, etc., and the oxygen content is less than 2%; the cathode electrode 11 in the charging area adopts a double-area half-bone spur electrode, the electrode material is stainless steel, and the anode electrode is a high-temperature electric heating electric filter coupling component 9. It adopts silicon carbide material, which is a hollow cylindrical cage with micropores welded vertically and horizontally by longitudinal ribs and support rings, with a pore diameter of 20 μm; and the cathode and anode are connected to an 80kv DC high-voltage power supply 13. Corona disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com